What is Steam Engine?

A steam engine is a heat engine that uses steam as a working medium to do mechanical work. A steam engine uses the force generated with the aid of the stress of the steam to push a piston from side to side in a cylinder.

This thrust is converted through a connecting rod and a flywheel into rotational pressure for paintings. The term “steam engine” usually applies best to the piston engine just described, not to steam generators.

A steam engine is an outside combustion engine in which the running fluid is separated from the goods of combustion. The ideal thermodynamic cycle used to analyze this process is referred to as the Rankine cycle.

In not unusual usage, the time period steam engine can consult with a whole steam device (inclusive of boiler etc.), together with a steam locomotive or portable engine, or to most effective piston or turbine machines, along with a balancing engine or a stationary steam engine.

Although steam-powered devices have been known as early because the 1st century AD, inclusive of the aeolipile, and some different uses are recorded in the sixteenth and seventeenth centuries, Thomas Savery is credited with being the inventor of the primary commercially used steam-powered device. The device involves a steam pump working on steam stress that at once affects water.

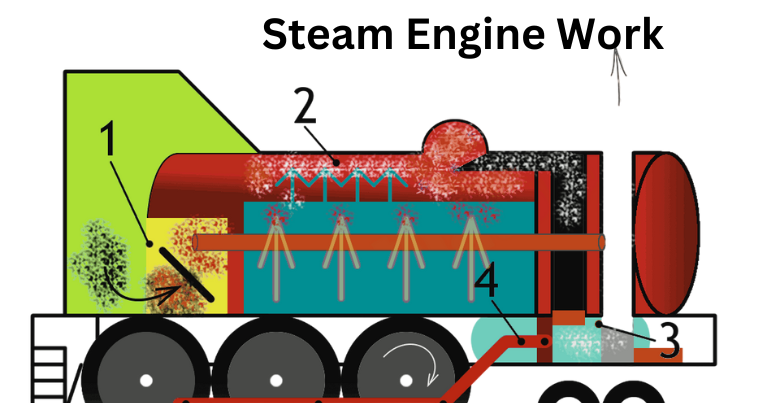

How Does a Steam Engine Work?

In a steam engine, hot steam, generally furnished through a boiler, expands underneath strain and a number of the thermal energy is converted into paintings. The residual warmth may be allowed to escape, or the steam may be condensed at particularly low temperatures and pressures in a separate device, the condenser, to obtain most engine performance.

To reap excessive efficiency, the steam have to skip through a extensive variety of temperatures as it expands inside the gadget. Maximum efficiency, this is, the most quantity of labor in line with unit of warmth furnished, is executed by using keeping the condenser temperature low and the boiler stress excessive.

The steam can be heated similarly with the aid of passing thru a superheater on its manner from the boiler to the system. A typical superheater is a sequence of parallel tubes whose surfaces are exposed to the recent gases inside the boiler furnace. Superheaters can be used to warmth steam above the temperature at which water boils and produces steam.

In a reciprocating or piston-cylinder steam engine, pressurized steam flows thru a valve mechanism into a cylinder. As the steam expands, it pushes on a piston, that is typically linked to a crank on a flywheel, inflicting rotational movement. In a double-performing engine, steam from the boiler flows alternately on either side of the piston.

In a simple steam engine, steam manufacturing takes area in most effective one cylinder, however in a compound engine there are one or extra cylinders of growing period to reap extra steam manufacturing and better energy output.

The first and smallest piston is pushed via the primary excessive-strain steam, and the second one piston is driven by means of the low-stress steam leaving the first piston. In a steam turbine, steam shoots out at excessive speed from a nozzle and passes via a sequence of fixed and moving blades to force a rotor at high speed. Steam generators are greater compact than reciprocating steam engines and can commonly acquire higher temperatures and more charges of expansion. Turbines are a common method of the use of steam to generate large amounts of electrical energy.

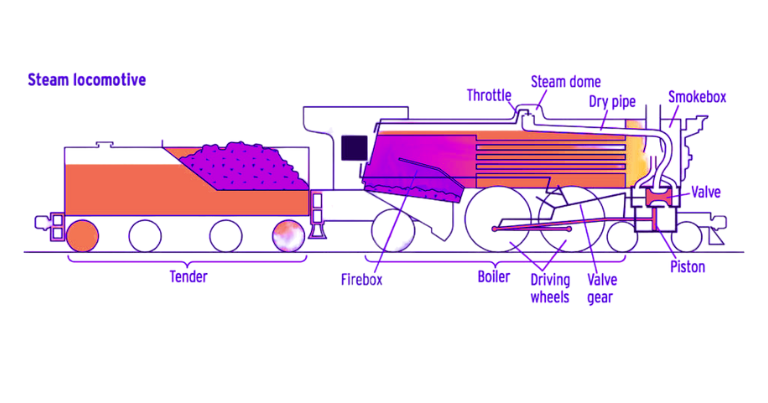

Parts of Steam Engine

- Firebox: Where fuel is burned to produce warmness.

- Boiler: Lindy uses a fireplace-tube boiler. Hot gases produced in the firebox are drawn into the boiler thru a framework of pipes. The pipes heat the encircling water, generating steam. The steam collects in a steam dome on the pinnacle of the boiler.

- Steam Dome: The manipulate valve, safety valve, and whistle are located inside the steam dome. The control valve is hooked up to a throttle manage in the cabin. The teach driving force uses the throttle to manipulate the quantity of steam provided to the cylinder. The whistle is a 1st Earl Baldwin of Bewdley whistle with 4 bells made in 1925, and is blown via steam stress. If the strain gets too excessive the protection valve opens to launch the steam.

- Valves, Cylinders and Pistons: In the cylinder, steam is transformed into mechanical electricity. Pressurized steam is admitted through the cylinder valve into a chamber which drives the piston. The Lindy, like maximum locomotives, uses a double-acting cylinder. This is executed via supplying steam alternately to both facet of the piston, pushing and pulling the piston rod, generating power on both strokes, thus reaching double energy.

- Rods: The piston is aligned within the cylinder by means of a move member which sits on a guide. The crosshead includes the small cease of the connecting rod. The different stop, the huge end, transmits electricity to the wheels thru the crank pin. Like maximum locomotives, the Lindy has numerous riding wheels to divide the electricity generated through the double-appearing cylinders. The cranks on either side of the locomotive are offset by way of 90° to distribute the strength until the wheels have finished one revolution.

- Smokebox: Spent steam leaves the cylinders via a blowpipe down the chimney. This arrangement creates a stress drop inside the smokebox, drawing firebox gases thru the boiler tubes. The tougher the locomotive works, the extra fuel is drawn thru the pipes and the extra steam is produced.

- Chimney: Spent steam from the blowpipe mixes with gases from the boiler pipes and exits through the chimney. The more difficult the locomotive works, the greater gas and steam pop out of the chimney.

- Cab: The team operates the machinery from the cab. The stoker’s process is to manipulate the hearth inside the firebox and the water supply to the boiler to provide steam. The educate motive force operates the throttle and video display units the steam strain, fuel, and water to apply the steam.

- Sand Dome: The dome includes sand that the teach motive force sprays in the front of and in the back of the using wheels to offer traction among the wheels and the rails.

Who Invented the Steam Engine?

The first commercially successful engine able to constantly transmitting strength to a system turned into evolved through Thomas Newcomen in 1712. James Watt made a essential improvement by way of directing the spent steam right into a separate vessel for condensation, thereby significantly improving the paintings received according to unit of gas ate up.

In the 19th century, desk bound steam engines powered factories at some stage in the Industrial Revolution. Steam engines replaced sails on paddle steamers, and steam locomotives ran on railroads.

Until the early 20th century, reciprocating steam engines were the number one supply of energy, however advances in electric powered motor and internal combustion engine layout gradually changed steam engines in industrial applications. Steam mills changed piston engines in producing electricity because of their decrease fee, faster operating speed, and more efficiency.