What is an O-Ring?

An O-rings is a spherical elastic loop that is used as a seal for static and dynamic programs. Their principal purpose is to serve as a seal among structures which include pipes, tubes, in pistons, and cylinders. O-rings are made of diverse materials relying on how they’ll be used and are enormously pliable. When positioned among surfaces, they block the leakage of drinks or gases.

dependin.

When used as a static seal, an O-ring remains stationary to comprise strain or seal a vacuum. The dynamic shape of the O-ring can be reciprocating or rotating. O-ring are a self-energizing seal that applies stress inner a tube or pipe to form a seal.

Types of O-Rings

There are an endless wide variety of O-rings with simply as many packages. Although they’re a small round part fabricated from a huge assortment of materials, O-ring are an important part of mechanisms and gadgets. The type of O-ring depends on the form of cloth from which they’re made, and the software for which they’re intended. In the layout technique, engineers specify the sort of O-ring that could be essential for software.

Nitrile O-Rings

Nitrile O-rings have a temperature range of -50° C as much as 120° C (-58° F as much as 248° F). Known as buna-N or NBR O-rings, nitrile O-rings are usually used due to their resistance to ripping and having had an abrasive treatment. An issue regarding their use is their resistance to the effects of water, oils, and hydraulic fluids. Nitrile O-rings may be damaged by using sure hydrocarbons, brake fluid, ketones, and phosphate esters.

Viton O-Rings

Often called FKM O-rings due to their fluorocarbon base, VitonTM O-rings have excellent mechanical houses, low gas permeability, and low compression set with a temperature range of -forty° C as much as 250° C (-40° F up to 482° F). They are not susceptible to the effects of acids, halogenated hydrocarbons, petroleum, or silicone fluids and gases but ought to now not be used inside the presence of heated hydrofluoric acids, amines, esters, Skydrol & ethers, like dimethyl, methyl ethyl, or diethyl. The popularity of VitonTM O-ring is because of their capacity to be tailored to any set of conditions.

Silicone O-Rings

Capable of withstanding temperatures of -one hundred° C as much as three hundred° C (-148° F as much as 572° F), silicone O-rings have the widest temperature tolerance range of any of the O-ring substances with an extreme range of -one hundred fifteen° C to 315° C (-one hundred seventy five° F to 600° F) for brief durations of time. Regardless of their many advantageous homes, which include their resistance to the results of water, steam, and petroleum, silicone O-rings are liable to ripping and damage from abrasions, which makes them ideal for static applications.

Teflon (PTFE) O-Rings

One of the principles made use of for Teflon O-ring is in packages with intense warmness wherein chemical compounds, solvents, and anti-adhesives are getting used. They have splendid tensile and compressive homes because of their PTFE content, which offers them dielectric houses, a low friction coefficient, and non-toxicity. Teflon O-ring can be used constantly at 250°C (482°F) and have compressive plasticity near zero stages. The temperature range of Teflon O-rings is -2 hundred°C as much as 250°C (-328°F up to 482°F).

Clear O-Rings

Clear O-ring, called medical O-ring, are a uniqueness O-ring used in applications that require a seal that may be visually checked and monitored. They are made of silicone or fluorocarbon that lets in for easy detection of contamination, damage, or deformation. The necessity of visual inspection is vital in packages involving high-precision machines or laboratory equipment. They are a vital part of meal manufacturing and scientific devices as a means of hygiene.

Flat O-Rings

The traditional and not unusual profile of an O-ring is spherical. This isn’t the case with flat O-rings, that have a square or rectangular profile, called torus shapes. They are utilized in spaces in which traditional O-rings do not healthy however provide the equal tight seal of round O-ring. Flat O-ring are encouraged for rotary sealing and hydraulic and pneumatic device. They require much less stress to create a seal and may be without problems changed. Flat O-ring final longer, value much less, and have much less put on and tear, which removes the want for lubrication.

Large O-Rings

The manufacture of massive O-ring requires the usage of unique methods because the normal methods of O-ring production are unable to meet the desires of huge O-rings. A commonplace method used to produce huge O-rings is thermobonding, referred to as spliced and vulcanized. In the thermobonding system, the joints of the O-ring are sealed with an adhesive and cured, which gives the O-ring notable flexibility. Large O-rings are used in the chemical industry, meals processing, electronics industry, and prescription drugs where they’re carried out to a couple of programs from panel shows to string tube fittings.

Metal O-Rings

Metal O-rings have minimum spring back and are used for high temperature and high-pressure programs wherein there are fluids in exhausts, soften move plastics, combustion, hydraulics, and valves. They are adaptable to excessive warmth, bloodless, pressure, and vacuums and are used whilst the wishes of an software exceeds the capabilities of polymer O-rings.

Metal O-rings are pretty reliable and remaining for years. They are the only form of O-ring capable of creating a four-factor seal. Metal O-rings are corrosion, pressure, and temperature resistant and may be synthetic with a protection of plastic while complete contact is essential.

The metal used most to make metallic O-ring is stainless steel because of its amazing houses and traits. Metal O-rings have a temperature range of -267° C as much as 704° C (-450° F as much as 1300° F). They are crafted from coiled steel tubing this is cut and welded to length. Wall thickness, OD and ID, and cross-sectional profiles range to match the wishes of a utility.

Metric O-Rings

Metric O-ring serve the same features as imperial size gadget O-rings but are manufactured with the usage of metric measurements for the OD, ID, and cross-phase profile. They are designed to be used in nations that use the metric device for the manufacture of machines and equipment. Most producers provide O-rings in both imperial and metric measurements and are to be had inside identical substances as the ones produced the use of the imperial measurement gadget.

O-Ring Seals

O-ring seals are dynamic seals used on rotating or reciprocating equipment, which include pistons, cylinders, and rotating shafts. They rest in a gland or groove that holds them in place between equipment connections to create an air and water-tight seal. O-ring seals are capable of withstanding high strain, various temperatures, and intense pressure.

An O-ring seal rests in a gland until strain is applied. At this time, it rises within the sealing device, shifts away from the stress, and is robotically squeezed to plug the hole between the related equipment. O-ring seal temperature levels range in step with the kind of fabric used to create the seal with temperatures being as little as -fifty five° C (-sixty seven° F) to as excessive as 205° C (401° F).

Rubber O-Rings

The first O-ring, added for the duration of the first business revolution, have been fabricated from rubber through J. O. Lundberg of Sweden and were brought to the USA in 1891 via Niels Christensen, who filed a patent for his layout in 1937. Since its initial introduction, rubber O-ring were changed and altered with the addition of elastic polymers that provide a higher seal and feature extra balance. A dramatic exchange in O-ring production passed off in 1986 because of the Challenger catastrophe.

During an investigation of the catastrophe, it became observed that the explosion changed into as a result of an O-ring that failed due to too low of a temperature. Using what they had discovered, engineers have designed extra resilient and reliable O-rings.

The term rubber O-ring covers a wide collection of artificial rubbers used to supply O-ring, every of that is designed to meet the situations of a variety of programs, conditions, and environments. Each type of synthetic rubber O-ring has a unique temperature variety, chemical resistance, and pressure variant. Nitrile and VitonTM are of the maximum common styles of artificial rubbers used to provide synthetic rubber O-ring.

High Temperature O-Rings

One of the motives for the usage of O-ring is their potential to hold a seal via a huge variety of temperatures from intense lows to extreme highs. High-temperature O-ring are categorized by using the best temperature they can withstand for over 1000 hours determined via an evaluation of the software in which they will be used. The temperature range for high-temperature O-ring levels between 204°C (400°F) and 316°C (600°F).

Types of materials used for high-temperature O-ring and their most temperatures:

- Perfluorinated (FFKM) up to six hundred°F (316°C)

- Tetrafluoroethylene-Propylene (TFE, AFLAS) up to 450°F (232°C)

- Silicone (VMQ) as much as 400°F (204°C)

- Fluorocarbon (FKM, VITON) as much as 400°F (204°C)

- Fluorosilicone (FMQ, FVMQ) as much as 400°F (204°C)

When an O-ring is uncovered to a temperature beyond its abilities, it hardens and turns brittle, which ends up within the O-ring cracking, leaking, and compression set due to the loss of elasticity.

High-temperature O-ring are synthetic in diverse colors as a technique of differentiating them for OEM part identification, which allows avoid assembly and restoration mistakes. Of the various styles of O-ring, high-temperature O-rings are the most fantastically valued due to their reliability and balance.

How O-Rings are Used

O-ring were a staple part of numerous machines in view that their inception on the quit of the 19th Century. Their ability to seal and include gases and drinks have made them an vital part of device layout. As era has advanced, evolved, and superior, the simple O-ring and its use has advanced and grown from the simple primary rubber layout to a wide sort of materials and applications.

Applications O-Ring: Static vs Dynamic

The applications of O-rings are decided via the motion that occurs between two surfaces with static relating to two components that don’t flow even as dynamic refers to elements that circulate when it come to each other. Where there’s reciprocating, rotating, oscillating, or vertical and horizontal movement, the software is described as dynamic. Although the distinction among these programs is easy, the substances to produce them should be specially designed for the stress, tolerance, and conditions where the O-ring might be installed.

Static O-Ring

A static O-ring is designed to touch two or extra surfaces wherein there is no motion and sealing is parallel to the middle line of the seal. The sealing movement is at the top and bottom or face of the seal. With a face seal, a groove has been reduce in a flat surface. An O-ring of the right length and dimensions is located within the groove. A 2nd flat floor compresses the O-ring in location. Once the connection is made, the utility remains static, and the O-ring does not circulate. In the diagram beneath, the red component is the CS of the O-ring.

The carried-out stress forces the O-ring to the outdoor diameter of the groove, which fits the OD of the O-ring and minimizes the O-ring shifting or transferring inside the groove. Other forms of static O-rings consist of crush seals, dovetail glands, and radial seals.

Dynamic O-Ring

A dynamic seal occurs when there is motion between components and sealing is required. The movement can take several pieces of paperwork and might require multiple applications for an unmarried operation. The fabric used for dynamic O-ring has more complicated necessities since it has to be harder, stronger, and extra-proof against abrasion or friction.

The materials need to not abrade when the O-ring is in movement, which can tear and damage the O-ring. Unlike static applications, dynamic applications cause O-rings to wear quickly since the O-ring is constantly moving. For satisfactory results, dynamic O-rings should be often lubricated. Several factors affect the performance of dynamic O-rings, along with seal swell in fluids, surface end of metallic elements, lubrication, gadget strain, thermal cycling, O-ring squeeze, O-ring stretch, and friction. Since these elements do not arise personally, it is critical to study all feasible dynamic sealing situations.

Two not unusual sorts of dynamic O-ring uses are reciprocating and rotary. Valve stem sealing might also have a combination of these kinds.

- Reciprocating Seal A reciprocating seal refers to using a moving piston or rod, which is the maximum common form of dynamic O-ring usage. The elements that have to be taken into consideration for this form of utility are stress shock, squeeze, stretch, and thermal biking wherein there is a wide variation within the temperature. For the satisfactory effects with a reciprocating seal, surfaces ought to no longer be fairly finished due to the fact they will no longer be capable of preserve lubrication.

- Rotary Seal A rotary seal involves a turning shaft that protrudes from the ID. For this utility temperature, friction, seal stretch, squeeze, and type of shaft need to be examined. For rotary operations, shafts must be made from hard metallic with a 0.0005” TIR and with surfaces having a finish of sixteen RMS as well as being non-abrasive.

High Temperature

High-temperature programs require O-ring that are capable of withstanding elevated temperatures but be able to maintain their seal. The chart underneath gives a short review of a number of the famous kinds of O-ring substances and their temperature levels. Industries that require O-ring capable of withstanding high temperatures are refineries, chemical processing vegetation, rapid engines, and aerospace.

High Pressure

The most unusual use for the O-ring is in high-pressure packages, wherein pressure located at the O-ring creates deformation at the O-ring inside the groove. Uniform mechanical strain is placed on the floor of the O-ring. The key thing is that the strain gradient remains underneath the O-rings pressure rating. For the bulk of O-rings, it’s far impossible for seepage or leaks to occur whilst they’re placed below high stress.

In positive instances, extrusion and O-ring destruction can arise when there may be mechanical failure. This may be prevented by way of selecting the perfect O-ring material for the application.

In the case of an engine seal, O-rings need to be temperature, stress, and chemically well suited. Most rubbers and polymers do not have the power and resistance to be used for engine packages. In those instances, hybrid substances especially designed for the application are used.

Carbon Dioxide (CO2)

Carbon dioxide creates special issues for O-rings seeing that softer O-ring substances take in gasoline and swell, which ends up in an unreliable seal. If not contained, the O-ring will crack and wreck down.

Vacuum

Vacuum O-ring is used on compressors and UHV pumps. The material used for the manufacture of vacuum O-rings is impermeable, deforms into the sealing floor, and is outgassing. The sealing surface needs to be tough, flat, and have a surface finish, which lets in the O-ring to nicely deform into the groove.

Every O-ring has an exclusive permeation fee depending on the type of gasoline. Silicone has a high price of permeability for air, while FKM and Viton™ do now not. Vacuum seal O-rings are capable of adapting to the unevenness of the vacuum’s floor and feature grease applied to smooth the unevenness of the floor and the O-ring. O-rings used for vacuum applications are static.

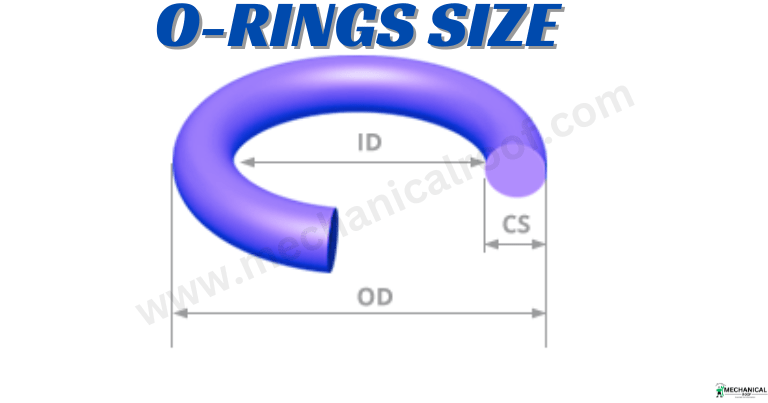

Sizes of O-Rings

The length of an O-ring is defined by means of its internal diameter (ID) and pass sectional diameter (CS). The ID dimensions of O-rings are determined by way of the AS568D sizing widespread (although there may be a Japanese sizing gadget).

AS568D is the aerospace size trendy for O-rings from the Society of Automotive Engineers (SAE). The records in AS568D specifies the internal diameters, go phase diameters, and tolerances in addition to together with a numbering code for O-ring for sealing applications. The chart for sizing O-rings using AS568D includes length configurations in inches and millimeters. The definitions it outlines are those that maximum manufacturers use for determining the scale of their products.

Each O-ring size is written as AS568-XXX to pick out any individual one. For general use, AS568 is removed leaving the last three digits. Each of the digits is an figuring out function of the O-ring, wherein the first digit identifies the CS and the second digit defines the ID. To completely apprehend the sizing, it is important to consult the AS568D chart.

Measuring an O-Ring

Inner Diameter

Measuring the inner diameter of an O-ring is a simple depend of putting the beginning of a tape degree at the internal fringe of one facet of the O-ring and reading the dimension on the internal area at the other aspect. The right size of the O-ring ID guarantees that once it’s miles positioned underneath stress that it’ll not extrude into the gap between the surfaces. The ID have to healthy the diameter of the groove where the O-ring may be located.

Cross Section

The go segment is the width of 1 side of the O-Ring, or the width of the material that makes up the ring. The CS is the width of the cloth that makes up the circumference of the O-ring. It may be measured via laying the O-ring on a flat surface and taking a dimension of the width of the material. O-Rings have CSs zero.040, zero.070, zero.103, and zero.139″.

Standard metric sizes start at 1 mm CS to five mm CS. Of the three measurements, the CS is the maximum critical on the grounds that it’s miles the portion of the O-ring that fits into the groove of the software and must be precisely decided to keep away from O-ring failure and leaks.

| Cross Section (MM) | Inside Diameter (MM) | Outside Diameter (MM) |

| 1.02 | 0.74 | 2.78 |

| 1.27 | 1.07 | 3.61 |

| 1.52 | 1.42 | 4.46 |

| 1.78 | 1.78 | 5.34 |

| 1.78 | 2.57 | 6.13 |

| 1.78 | 2.90 | 6.46 |

| 1.78 | 3.68 | 7.24 |

| 1.78 | 4.47 | 8.03 |

| 1.78 | 5.28 | 8.84 |

| 1.78 | 6.07 | 9.63 |

| 1.78 | 7.65 | 11.21 |

| 1.78 | 9.25 | 12.81 |

| 1.78 | 10.82 | 14.38 |

| 1.78 | 12.42 | 15.98 |

| 1.78 | 14.00 | 17.56 |

| 1.78 | 15.60 | 19.16 |

| 1.78 | 17.17 | 20.73 |

| 1.78 | 18.77 | 22.33 |

| 1.78 | 20.35 | 23.91 |

| 1.78 | 21.95 | 25.51 |

| 1.78 | 23.52 | 27.08 |

| 1.78 | 25.12 | 28.68 |

| 1.78 | 26.70 | 30.26 |

| 1.78 | 28.30 | 31.86 |

| 1.78 | 29.87 | 33.43 |

| 1.78 | 31.47 | 35.03 |

| 1.78 | 33.05 | 36.61 |

| 1.78 | 34.65 | 38.21 |

| 1.78 | 37.82 | 41.38 |

| 1.78 | 41.00 | 44.56 |

| 1.78 | 44.17 | 47.73 |

| 1.78 | 47.35 | 50.91 |

| 1.78 | 50.52 | 54.08 |

| 1.78 | 53.70 | 57.26 |

| 1.78 | 56.87 | 60.43 |

| 1.78 | 60.05 | 63.61 |

| 1.78 | 63.22 | 66.78 |

| 1.78 | 66.40 | 69.96 |

| 1.78 | 69.57 | 73.13 |

| 1.78 | 72.75 | 76.31 |

| 1.78 | 75.92 | 79.48 |

| 1.78 | 82.27 | 85.83 |

| 1.78 | 88.62 | 92.18 |

| 1.78 | 94.97 | 98.53 |

| 1.78 | 101.32 | 104.88 |

| 1.78 | 107.67 | 111.23 |

| 1.78 | 114.02 | 117.58 |

| 1.78 | 120.37 | 123.93 |

| 1.78 | 126.72 | 130.28 |

| 1.78 | 133.07 | 136.63 |

| 2.62 | 1.24 | 6.48 |

| 2.62 | 2.06 | 7.30 |

| 2.62 | 2.84 | 8.08 |

| 2.62 | 3.63 | 8.87 |

| 2.62 | 4.42 | 9.66 |

| 2.62 | 5.23 | 10.47 |

| 2.62 | 6.02 | 11.26 |

| 2.62 | 7.59 | 12.83 |

| 2.62 | 9.19 | 14.43 |

| 2.62 | 10.77 | 16.01 |

| 2.62 | 12.37 | 17.61 |

| 2.62 | 13.94 | 19.18 |

| 2.62 | 15.54 | 20.78 |

| 2.62 | 17.12 | 22.36 |

| 2.62 | 18.72 | 23.96 |

| 2.62 | 20.29 | 25.54 |

| 2.62 | 21.89 | 27.13 |

| 2.62 | 23.47 | 28.71 |

| 2.62 | 25.07 | 30.31 |

| 2.62 | 26.64 | 31.88 |

| 2.62 | 28.24 | 33.48 |

| 2.62 | 29.82 | 35.06 |

| 2.62 | 31.42 | 36.66 |

| 2.62 | 32.99 | 38.23 |

| 2.62 | 34.59 | 39.83 |

| 2.62 | 36.17 | 41.41 |

| 2.62 | 37.77 | 43.01 |

| 2.62 | 39.34 | 44.58 |

| 2.62 | 40.94 | 46.18 |

| 2.62 | 42.52 | 47.76 |

| 2.62 | 44.12 | 49.36 |

| 2.62 | 45.69 | 50.93 |

| 2.62 | 47.29 | 52.54 |

| 2.62 | 48.90 | 54.14 |

| 2.62 | 50.47 | 55.71 |

| 2.62 | 52.07 | 57.31 |

| 2.62 | 53.64 | 58.88 |

| 2.62 | 55.25 | 60.49 |

| 2.62 | 56.82 | 62.06 |

| 2.62 | 58.42 | 63.66 |

| 2.62 | 59.99 | 65.23 |

| 2.62 | 61.60 | 66.84 |

| 2.62 | 63.17 | 68.41 |

| 2.62 | 64.77 | 70.01 |

| 2.62 | 66.34 | 71.58 |

| 2.62 | 67.95 | 73.19 |

| 2.62 | 69.52 | 74.76 |

| 2.62 | 71.12 | 76.36 |

| 2.62 | 72.69 | 77.93 |

| 2.62 | 75.87 | 81.11 |

| 2.62 | 82.22 | 87.46 |

| 2.62 | 88.57 | 93.81 |

| 2.62 | 94.92 | 100.16 |

| 2.62 | 101.27 | 106.51 |

| 2.62 | 107.62 | 112.86 |

| 2.62 | 113.97 | 119.21 |

| 2.62 | 120.32 | 125.56 |

| 2.62 | 126.67 | 131.91 |

| 2.62 | 133.02 | 138.26 |

| 2.62 | 139.37 | 144.61 |

| 2.62 | 145.72 | 150.96 |

| 2.62 | 152.07 | 157.31 |

| 2.62 | 158.42 | 163.66 |

| 2.62 | 164.77 | 170.01 |

| 2.62 | 171.12 | 176.36 |

| 2.62 | 177.47 | 182.71 |

| 2.62 | 183.82 | 189.06 |

| 2.62 | 190.17 | 195.41 |

| 2.62 | 196.52 | 201.76 |

| 2.62 | 202.87 | 208.11 |

| 2.62 | 209.22 | 214.46 |

| 2.62 | 215.57 | 220.81 |

| 2.62 | 221.92 | 227.16 |

| 2.62 | 228.27 | 233.51 |

| 2.62 | 234.62 | 239.86 |

| 2.62 | 240.97 | 246.21 |

| 2.62 | 247.32 | 252.56 |

| 3.53 | 4.34 | 11.40 |

| 3.53 | 5.94 | 13.00 |

| 3.53 | 7.52 | 14.58 |

| 3.53 | 9.12 | 16.18 |

| 3.53 | 10.69 | 17.75 |

| 3.53 | 12.29 | 19.35 |

| 3.53 | 13.87 | 20.93 |

| 3.53 | 15.47 | 22.53 |

| 3.53 | 17.04 | 24.10 |

| 3.53 | 18.64 | 25.70 |

| 3.53 | 20.22 | 27.28 |

| 3.53 | 21.82 | 28.88 |

| 3.53 | 23.39 | 30.45 |

| 3.53 | 24.99 | 32.06 |

| 3.53 | 26.57 | 33.63 |

| 3.53 | 28.17 | 35.23 |

| 3.53 | 29.74 | 36.80 |

| 3.53 | 31.34 | 38.40 |

| 3.53 | 32.92 | 39.98 |

| 3.53 | 34.52 | 41.58 |

| 3.53 | 36.09 | 43.15 |

| 3.53 | 37.69 | 44.75 |

| 3.53 | 40.87 | 47.93 |

| 3.53 | 44.04 | 51.10 |

| 3.53 | 47.22 | 54.28 |

| 3.53 | 50.39 | 57.45 |

| 3.53 | 53.57 | 60.63 |

| 3.53 | 56.74 | 63.80 |

| 3.53 | 59.92 | 66.98 |

| 3.53 | 63.09 | 70.15 |

| 3.53 | 66.27 | 73.33 |

| 3.53 | 69.44 | 76.50 |

| 3.53 | 72.62 | 79.68 |

| 3.53 | 75.79 | 82.85 |

| 3.53 | 78.97 | 86.03 |

| 3.53 | 82.14 | 89.20 |

| 3.53 | 85.32 | 92.38 |

| 3.53 | 88.49 | 95.55 |

| 3.53 | 91.67 | 98.73 |

| 3.53 | 94.84 | 101.90 |

| 3.53 | 98.02 | 105.08 |

| 3.53 | 101.19 | 108.25 |

| 3.53 | 104.37 | 111.43 |

| 3.53 | 107.54 | 114.60 |

| 3.53 | 110.72 | 117.78 |

| 3.53 | 113.89 | 120.95 |

| 3.53 | 117.07 | 124.13 |

| 3.53 | 120.24 | 127.30 |

| 3.53 | 123.42 | 130.48 |

| 3.53 | 126.59 | 133.65 |

| 3.53 | 129.77 | 136.83 |

| 3.53 | 132.94 | 140.00 |

| 3.53 | 136.12 | 143.18 |

| 3.53 | 139.29 | 146.35 |

| 3.53 | 142.47 | 149.53 |

| 3.53 | 145.64 | 152.71 |

| 3.53 | 148.82 | 155.88 |

| 3.53 | 151.99 | 159.05 |

| 3.53 | 158.34 | 165.40 |

| 3.53 | 164.69 | 171.75 |

| 3.53 | 171.04 | 178.10 |

| 3.53 | 177.39 | 184.45 |

| 3.53 | 183.74 | 190.80 |

| 3.53 | 190.09 | 197.15 |

| 3.53 | 196.44 | 203.50 |

| 3.53 | 202.79 | 209.85 |

| 3.53 | 209.14 | 216.20 |

| 3.53 | 215.49 | 222.55 |

| 3.53 | 221.84 | 228.90 |

| 3.53 | 228.19 | 235.25 |

| 3.53 | 234.54 | 241.60 |

| 3.53 | 240.89 | 247.95 |

| 3.53 | 247.24 | 254.30 |

| 3.53 | 253.59 | 260.65 |

| 3.53 | 266.29 | 273.35 |

| 3.53 | 278.99 | 286.05 |

| 3.53 | 291.69 | 298.75 |

| 3.53 | 304.39 | 311.45 |

| 3.53 | 329.79 | 336.85 |

| 3.53 | 355.19 | 362.25 |

| 3.53 | 380.59 | 387.65 |

| 3.53 | 405.26 | 412.32 |

| 3.53 | 430.66 | 437.72 |

| 3.53 | 456.06 | 463.12 |

| 5.33 | 10.46 | 21.12 |

| 5.33 | 12.07 | 22.73 |

| 5.33 | 13.64 | 24.30 |

| 5.33 | 15.24 | 25.90 |

| 5.33 | 16.81 | 27.47 |

| 5.33 | 18.42 | 29.08 |

| 5.33 | 19.99 | 30.65 |

| 5.33 | 21.59 | 32.25 |

| 5.33 | 23.16 | 33.82 |

| 5.33 | 24.77 | 35.43 |

| 5.33 | 26.34 | 37.00 |

| 5.33 | 27.94 | 38.60 |

| 5.33 | 29.51 | 40.17 |

| 5.33 | 31.12 | 41.78 |

| 5.33 | 32.69 | 43.35 |

| 5.33 | 34.29 | 44.95 |

| 5.33 | 37.47 | 48.13 |

| 5.33 | 40.64 | 51.30 |

| 5.33 | 43.82 | 54.48 |

| 5.33 | 46.99 | 57.65 |

| 5.33 | 50.17 | 60.83 |

| 5.33 | 53.34 | 64.00 |

| 5.33 | 56.52 | 67.18 |

| 5.33 | 59.69 | 70.35 |

| 5.33 | 62.87 | 73.53 |

| 5.33 | 66.04 | 76.70 |

| 5.33 | 69.22 | 79.88 |

| 5.33 | 72.39 | 83.05 |

| 5.33 | 75.57 | 86.23 |

| 5.33 | 78.74 | 89.40 |

| 5.33 | 81.92 | 102.58 |

| 5.33 | 85.09 | 95.75 |

| 5.33 | 88.27 | 98.93 |

| 5.33 | 91.44 | 102.10 |

| 5.33 | 94.62 | 105.28 |

| 5.33 | 97.79 | 108.45 |

| 5.33 | 100.97 | 111.63 |

| 5.33 | 104.14 | 114.80 |

| 5.33 | 107.32 | 117.98 |

| 5.33 | 110.49 | 121.15 |

| 5.33 | 113.67 | 124.33 |

| 5.33 | 116.84 | 127.50 |

| 5.33 | 120.02 | 130.68 |

| 5.33 | 123.19 | 133.85 |

| 5.33 | 126.37 | 137.03 |

| 5.33 | 129.54 | 140.20 |

| 5.33 | 132.72 | 143.38 |

| 5.33 | 135.89 | 146.55 |

| 5.33 | 139.07 | 149.73 |

| 5.33 | 142.24 | 152.90 |

| 5.33 | 145.42 | 156.08 |

| 5.33 | 148.59 | 159.25 |

| 5.33 | 151.77 | 162.43 |

| 5.33 | 158.12 | 168.78 |

| 5.33 | 164.47 | 175.13 |

| 5.33 | 170.82 | 181.48 |

| 5.33 | 177.17 | 187.83 |

| 5.33 | 183.52 | 194.18 |

| 5.33 | 189.87 | 200.53 |

| 5.33 | 196.22 | 206.88 |

| 5.33 | 202.57 | 213.23 |

| 5.33 | 208.92 | 219.58 |

| 5.33 | 215.27 | 225.93 |

| 5.33 | 221.62 | 232.28 |

| 5.33 | 227.97 | 238.63 |

| 5.33 | 234.32 | 244.98 |

| 5.33 | 240.67 | 251.33 |

| 5.33 | 247.02 | 257.68 |

| 5.33 | 253.37 | 264.03 |

| 5.33 | 266.07 | 276.73 |

| 5.33 | 278.77 | 289.43 |

| 5.33 | 291.47 | 302.13 |

| 5.33 | 304.17 | 314.83 |

| 5.33 | 329.57 | 340.23 |

| 5.33 | 354.97 | 365.63 |

| 5.33 | 380.37 | 391.03 |

| 5.33 | 405.26 | 415.92 |

| 5.33 | 430.66 | 441.32 |

| 5.33 | 456.06 | 466.72 |

| 5.33 | 481.46 | 492.07 |

| 5.33 | 506.86 | 517.47 |

| 5.33 | 532.26 | 542.87 |

| 5.33 | 557.66 | 568.27 |

| 5.33 | 582.68 | 593.34 |

| 5.33 | 608.08 | 618.74 |

| 5.33 | 633.48 | 644.14 |

| 5.33 | 658.88 | 669.54 |

| 6.99 | 34.29 | 48.26 |

| 6.99 | 37.47 | 51.44 |

| 6.99 | 40.64 | 54.61 |

| 6.99 | 43.82 | 57.79 |

| 6.99 | 46.99 | 60.96 |

| 6.99 | 50.17 | 64.14 |

| 6.99 | 53.34 | 67.31 |

| 6.99 | 56.52 | 70.49 |

| 6.99 | 59.69 | 73.66 |

| 6.99 | 62.87 | 76.84 |

| 6.99 | 66.04 | 80.01 |

| 6.99 | 69.22 | 83.19 |

| 6.99 | 72.39 | 86.36 |

| 6.99 | 75.57 | 89.54 |

| 6.99 | 78.74 | 92.71 |

| 6.99 | 81.92 | 95.89 |

| 6.99 | 85.09 | 99.06 |

| 6.99 | 88.27 | 102.24 |

| 6.99 | 91.44 | 105.41 |

| 6.99 | 94.62 | 108.59 |

| 6.99 | 97.79 | 111.76 |

| 6.99 | 100.97 | 114.94 |

| 6.99 | 104.14 | 118.11 |

| 6.99 | 107.32 | 121.29 |

| 6.99 | 110.49 | 124.46 |

| 6.99 | 113.67 | 127.65 |

| 6.99 | 116.84 | 130.82 |

| 6.99 | 120.02 | 134.00 |

| 6.99 | 123.19 | 137.17 |

| 6.99 | 126.37 | 140.35 |

| 6.99 | 129.54 | 143.52 |

| 6.99 | 132.72 | 146.70 |

| 6.99 | 135.89 | 149.87 |

| 6.99 | 139.07 | 153.05 |

| 6.99 | 142.24 | 156.22 |

| 6.99 | 145.42 | 159.40 |

| 6.99 | 148.59 | 162.57 |

| 6.99 | 151.77 | 165.75 |

| 6.99 | 158.12 | 172.10 |

| 6.99 | 164.47 | 178.45 |

| 6.99 | 170.82 | 184.80 |

| 6.99 | 177.17 | 191.15 |

| 6.99 | 183.52 | 197.50 |

| 6.99 | 189.87 | 203.85 |

| 6.99 | 196.22 | 210.20 |

| 6.99 | 202.57 | 216.55 |

| 6.99 | 215.27 | 229.25 |

| 6.99 | 227.97 | 241.95 |

| 6.99 | 240.67 | 254.65 |

| 6.99 | 253.37 | 267.35 |

| 6.99 | 266.07 | 280.05 |

| 6.99 | 278.77 | 292.75 |

| 6.99 | 291.47 | 305.45 |

| 6.99 | 304.17 | 318.15 |

| 6.99 | 316.87 | 330.85 |

| 6.99 | 329.57 | 343.55 |

| 6.99 | 342.27 | 356.25 |

| 6.99 | 354.97 | 368.95 |

| 6.99 | 367.67 | 381.65 |

| 6.99 | 380.37 | 394.35 |

| 6.99 | 393.07 | 407.05 |

| 6.99 | 405.26 | 419.24 |

| 6.99 | 417.96 | 431.94 |

| 6.99 | 430.66 | 444.64 |

| 6.99 | 443.36 | 457.34 |

| 6.99 | 456.06 | 470.04 |

| 6.99 | 468.76 | 482.74 |

| 6.99 | 481.46 | 495.44 |

| 6.99 | 494.16 | 508.14 |

| 6.99 | 506.86 | 520.84 |

| 6.99 | 532.26 | 546.24 |

| 6.99 | 557.66 | 571.64 |

| 6.99 | 582.68 | 596.66 |

| 6.99 | 608.08 | 622.06 |

| 6.99 | 633.48 | 647.46 |

| 6.99 | 658.88 | 672.86 |

| 1.42 | 4.70 | 7.54 |

| 1.63 | 6.07 | 9.33 |

| 1.63 | 7.65 | 10.91 |

| 1.83 | 8.92 | 12.58 |

| 1.83 | 10.52 | 14.18 |

| 1.98 | 11.89 | 15.85 |

| 2.08 | 13.46 | 17.62 |

| 2.21 | 16.36 | 20.78 |

| 2.46 | 17.93 | 22.85 |

| 2.46 | 19.18 | 24.10 |

| 2.95 | 21.92 | 27.82 |

| 2.95 | 23.47 | 29.37 |

| 2.95 | 25.04 | 30.94 |

| 2.95 | 26.59 | 32.49 |

| 2.95 | 29.74 | 35.64 |

| 2.95 | 34.42 | 40.32 |

| 3.00 | 37.47 | 43.47 |

| 3.00 | 43.69 | 49.69 |

| 3.00 | 53.09 | 59.09 |

| 3.00 | 59.36 | 65.36 |

O-Ring Design and Materials

Though the original material used to produce O-ring became rubber, in recent years the range of substances has grown appreciably. The preference of a particular fabric depends on the final software for the O-ring, which is to serve as a seal among surfaces to prevent leakage of a gas or liquid.

The preference of material is a main factor in designing an O-ring. Other issues are the software, groove or gland layout and length, surrounding situations, and pass sectional diameter, or roundness, of the O-ring.

O-Ring Design

When analyzing the primary O-ring, the term design won’t appear to suit due to the fact that an O-ring is a circle made from an elastomer. In truth, there are numerous concerns that should be evaluated whilst generating an O-ring, which incorporates its internal diameter (ID) and go sectional (CS) diameter, hardness of its fabric, durability, and shape. Each of these factors is used to choose the perfect O-ring for the utility.

Steps to Designing an O-Ring

Step A- Choose a material that has the houses and traits for the utility.

Step B- A key component in selecting an O-ring is its capacity to withstand the situations it’s going to must bear. The fundamental subject is the temperature of the application, that may harm the pliability of the O-ring via increasing its cross-hyperlink density.

Step C– Different O-ring substances are capable of getting used with positive drinks and gases in view that some can resist the consequences of chemical substances and oil, while others are not designed for such conditions. During the layout phase, it’s far critical to consider, and carefully look at, the kinds of gases or liquids the O-ring can be subjected to.

Step D-The hardness of the O-ring has to suit the desires of the utility. O-ring range in hardness from rubber band softness to the hardened wheels of a shopping cart or conveyor.

Step E– A most important element within the layout of an O-ring is the dimensions of the groove or gland where it’ll be placed. The figuring-out element while selecting the right O-ring is the pass sectional (CS) dimensions of the O-ring, which may be visible in the chart under.

O-Ring Materials

As new programs for O-ring arise, one-of-a-kind substances had been adapted to match the multiplied need. The varieties of substances encompass several forms of rubber, silicone, and polymers. Materials which might be chosen for use as O-ring all have the equal primary features and traits, that’s their elasticity and strength considering that O-rings are typically positioned in crucial and traumatic situations.

Polytetrafluoroethylene (PTFE) O-Rings

Polytetrafluoroethylene, or PTFE, O-rings are white in shade and are valued for being nonreactive to acids, bases, solvents, oils, alkalis, and oxidants. They are able to perform in temperatures from -one hundred° F to 500° F (-seventy three° C to 260° C). PTFEO-rings are difficult and abrasive resistant however cannot be without difficulty compressed, resulting in a much less steady sealing.

Unlike different elastomers, PTFE O-rings do not degrade over time and feature a long shelf lifestyles. Additionally, they’re not affected by ultraviolet light and do no longer generate friction. PTFE O-rings are self lubricating and, because of their low friction, are perfect for use as hoses and pipes.

Silicone

Silicone is made from silicon, an detail that is taken from quartz. It is produced by way of combining it with organic companies like methyl, phenyl, or vinyl. The addition of those additional factors determines the residence of the silicone cloth. Silicone is resistant to the consequences of oils, chemical compounds, heat, ozone, corona, and solvents. It is known to preserve its flexibility at low temperatures. Typical silicone can operate at temperatures between -60° to 225° C with mainly designed versions capable of resisting temperatures starting from -100° to 300° C.

Viton

Viton is a synthetic fluoropolymer elastomer rubber used for O-rings in disturbing, harsh, and rigorous situations. They are the primary desire for packages that require an O-ring that may bear intense warmth and intense atmospheric situations where oxygen, mineral oil, various fuels, hydraulic fluids, chemical compounds, and solvents are gift. Viton O-rings keep splendid overall performance in hot temperature conditions.

Nitrile butadiene rubber (NBR)

NBR is referred to as acrylonitrile butadiene or Buna-N. It is a artificial rubber copolymer crafted from butadiene and acrylonitrile. NBR has excellent mechanical residences and put on resistance, that’s encouraged through the percentage of the numerous compounds from which it’s far produced. The higher the nitrile content material, the higher is its resistance to the effects of oil and fuels. It is used in packages which have dilute acids, alkalis, and salt answers present and springs in a extensive form of colors.

Ethylene Propylene (EPDM or EPM)

EPDM is a terpolymer made from ethylene and propylene with a monomer along with diolefin to set off vulcanization. It has resistance to ozone, daylight, and weathering with precise flexibility at low temperatures. EPDM is used for O-rings because of its resistance to dilute acids, alkalis, and positive solvents as well as its electric insulation homes. It is available in numerous shades for programs that require sealing phosphate ester based totally hydraulic fluids and glycol based brake fluids. Some of EPDM’s further packages are situations in which there’s hot water or steam as much as a hundred and fifty° C.

Polyurethane

Polyurethane rubber is a thermoplastic elastomer that is made with the aid of reacting a polyol with a diisocyanate or polymeric isocyanate with some form of catalyst. It has high power and is proof against tears and abrasions with superb preventative leakage capability. The many features of polyurethane O-ring consist of resistance to hydraulic oil, gas, hydrocarbons together with propane, grease, water, oxygen, and getting older. It is frequently used for hydraulic, cylinder, and valve fittings as well as pneumatic gear and firearms.

Fluorosilicone (FLS)

Fluorosilicone has the same homes as silicone however incorporates trifluoropropyl, which increases its resistance to solvents, oil, gas, acid, and alkaline. It is used as a static seal in aerospace, car, and aviation applications. Fluorosilicone has homes that are commonplace for fluorocarbons. Some of its blessings encompass excellent flexibility, getting old qualities, and UV ray resistance. The use of fluorine in its production affords its resistance to a wide range of chemicals as well as lower floor power.

Neoprene (CR)

Neoprene is a homopolymer made from chloroprene. It is one of the earliest of the synthetic rubbers utilized for sealing. In the manufacturing method, neoprene starts as a polychloroprene in powder form. Other substances are introduced to persuade mobile length, adhesion, bulk, and colour. Once the elements are combined, they may be positioned in a heat press and formed into sheets for the extrusion technique. There are numerous uses for neoprene in view that it is proof against oxidation and weather. One of its principal benefits is its low value.

Chlorosulfonated polyethylene (CSM)

CSM O-rings are made by means of treating polyethylene with a aggregate of chlorine and sulfur dioxide inside the presence of UV radiation. The variation in chlorine content is between 20 and 40% with a small percentage of chlorosulfonyl. The aggregate of those factors enables inside the vulcanization process, which impacts the strength of the very last product. CSM O-rings are resistant to dilute acids, alcohol, ozone, oxidation, and weathering. They are mainly used for static programs seeing that they’ve a low compression resistance.

How O-Rings are Made

The production and production of O-rings involves the usage of extrusion or injection, compression, and switch molding. The extrusion part of the system is used to form elastomers for the molding process.

Selecting the Mold

The mold for O-rings has two halves. The fabric is compressed between the two sections. The preference of the O-ring mildew depends on the favored diameter. Since the fabric expands while it’s far compressed, the groove width need to be 1.5 instances its diameter. For custom O-rings, new mould equipment are computer designed and produced to suit any length this is required. O-ring blanks are reduce from metal the use of a lathe.

For immediately manufacturing of O-ring, spliced and vulcanized O-ring manufacturing can be used and does no longer contain the usage of a tooled die but is crafted from extruded elastomer twine.

Material Selection

Choosing the correct material for the O-rings application is vital to ensure its right performance. The chemical compatibility, temperature resistance, and miscellaneous other factors decide the sort of fabric to be chosen as well as its utility.

O-rings are made from numerous sorts of elastomers with the greater traditional ones being PTFE, Nitrile (Buna), Neoprene, EPDM Rubber, Fluorocarbon (VitonTM), and Silicone with silicone being used for high-temperature packages. The chart underneath is a quick listing of some O-ring materials and their residences. Elastomers get their overall performance and traits from the substances that are jumbled in them.

O-ring Properties

| O-ring Properties | Nitrile | Viton | Ethylene Propylene | Fluorosilicone | PTFE |

| Property | |||||

| Tensile Strength | Fair-Good | Good-Excellent | Good-Excellent | Good-Excellent | Excellent |

| Electrical Properties | Poor | Excellent | Excellent | Good | Excellent |

| Weather Resistance | Good | Good | Excellent | Good | Excellent |

| Ozone Resistance | Fair | Good | Excellent | Excellent | Excellent (450°F) |

| Heat Resistance | Good (225°F) | Excellent (400°F) | Excellent (275°F) | Excellent (400°F) | Excellent (-100°F) |

| Cold Resistance | Fair-Good (-40°F) | Fair (-25°F) | Good (-70°F) | Fair (-20°F) | Excellent |

| Steam Resistance | Good | Good | Good | Good | Excellent |

| Tear Resistance | Good | Good | Good | Fair | Excellent |

| Abrasion Resistance | Good | Good | Good | Good | Excellent |

| Acid Resistance | Good | Good | Good-Excellent | Good | Excellent |

| Petroleum Oil | Excellent | Excellent | Poor | Excellent | Excellent |

| Flame Resistance | Poor | Good | Poor | Good | Excellent |

| Vegetable Oil | Good | Excellent | Good | Excellent | Excellent |

Extrusion

During the extrusion method, the elastomer is fed into an extruder that heats the material and forces it thru a die. The method produces the preferred configurations to be located inside the mold in lengths of wire. The die decided on for the extrusion system is selected in line with the diameter of the finished O-ring

Molding

There are three molding strategies used in the manufacturing of O-rings, which are compression, switch, and injection.

Compression

Compression molding is used when there’s a need for a high volume small non-fashionable O-ring. With compression molding, the extruded cloth is placed in the mould hollow space and held at a high temperature under pressure, which forces it to take the form of the mildew.

Transfer

Transfer molding is a center ground among compression and injection molding. In the transfer manner, material is pressured into the mildew, at the same time as the mould is closed ensuing in better dimensional tolerances and much less environmental effect. Uniform stress is used to completely fill the mildew. The fabric for molding may be stable and be positioned in the switch pot from which it is pressured into the preheated mildew.

Injection

The injection technique involves pre-heating the fabric, that’s pressured below pressure via an injection nozzle. The material enters the enclosed mildew via a series of sprues. The molded material is left to chill and harden to the configuration of the mold cavity.

Post Mold Curing

Post-mildew curing enhances the physical houses and overall performance of the molded O-ring. Post-curing exposes the O-ring to expanded and increased temperatures as a means of enhancing its characteristics. It assists with the cross-linking procedure and improves tensile energy, flexibility, and the heat distortion temperature above what could occur if it had been cured at room temperature.

Spliced and Vulcanized Extrusions

Another procedure used for the manufacture of extruded twine is spliced vulcanization that does not use a die to create O-rings. Spliced vulcanized O-ring are crafted from extruded twine this is cut and bonded. They are used for static sealing applications, short manufacturing runs, or whilst only some O-rings are wished. They are made from a extensive kind of elastomers and come in any length.

To form a spliced and vulcanized O-ring, the extruded wire is reduce to the right duration and then the cut ends are joined the use of a bonding agent. The bonded and joined ends are placed in a excessive-temperature mold to form a molecular bond at the joint.

Spliced and vulcanized O-rings are for static use handiest and ought to no longer are available contact with transferring components. They aren’t endorsed for dynamic packages. Spliced and vulcanized O-ring are produced in small quantities and are perfect for quick production runs.

Finishing

After the O-rings are molded, they’ll have extra cloth around the aspects wherein the molds meet. This cloth, known as flash, has to be removed for the O-ring to have the right shape and length. Flash may be removed the use of 3 techniques to provide the O-ring its perfectly round form.

- Drumming – The O-rings are placed in a hastily rotating drum that includes stones. As the drum turns, the extra material is removed with the aid of rubbing towards the stones.

- Cryogenic – Cryogenic deflashing is a laptop managed technique that uses nitrogen fuel to freeze the O-rings inflicting the flash to freeze and later be removed with grit. It is a secure smooth system that removes outer diameter (OD) and internal diameter (ID) flash.

- Buffing – For large O-rings that can not be located in a drum, the flash is eliminated by means of the abrasive motion of a buffer.

Curing

Once the O-rings are deflashed, they want to be cured. How lengthy the O-rings are in the curing oven depends on the kind of elastomer and might range from some hours to an afternoon. The cause of this step is to stabilize the completed O-rrings and drive off any with the aid of contaminants from the production procedure.

Proper Care of O-Rings

Though O-ring are very sturdy and reputedly indestructible, depending on the software, they should be closely monitored for viable alternative. To extend the existence of an O-ring and make sure that it maintains its maximum level of overall performance, there are quite a few preservation moves which could preserve the O-ring and increase its usage.

For O-rings to work smoothly, they have to be freely of dirt and debris. Any form of foreign contaminant interferes with the O-rings capacity to squeeze into the groove or gland. To make sure that the seal is being maintained, it is crucial to look at, smooth, and lubricate an O-ring.

Installation

The first step in O-ring maintenance is at the time of installation. During the installation procedure, care need to be taken to make certain the groove or gland is free of any metallic piece which could reduce or pierce the O-ring. The O-ring need to be well positioned without twisting or torquing it, which could bring about a uniform seal. Proper lubrication and the addition of a tape overlaying will provide extra safety and increase the usefulness of an O-ring.

Cleaning

O-ring want to be frequently wiped clean with cleaning soap and water. Solvents inclusive of trichloroethylene and carbon tetrachloride can damage an O-ring and are dangerous. Soap and water in addition to methylated spirits are the least dangerous and help maintain an O-ring included. For obvious reasons, any form of sharp tool, even brushes should be avoided while cleaning an O-ring.

Lubrication

The surfaces of O-ring have to have a skinny coating of lubricant, for you to amplify their life. The greatest quantity of harm to an O-ring to save you it from providing an ok seal is while it dries out.

Swelling

Swelling can come to be sizeable when an O-ring turns into much less round and flattened. In this situation, the O-ring has taken a permanent set and is not convalescing from being compressed main to a percentage loss in compressive capability. This may be prevented by way of ensuring that the O-ring does now not grow to be over-compressed.

Extrusion

Extrusion is without difficulty noticed. O-rings are placed among surfaces as a sealant. When the surfaces meet, a part of the O-ring can get stuck in among, which is known as extrusion. If it is going unrepaired, seepage and leaks can occur. It is essential to right away replace the O-ring.

Chemical Damage

During the inspection method, an O-ring may additionally show signs and symptoms of blistering, cracking, or discoloration. This can be resulting from exposure to chemicals, which can be prevented with the aid of the use of the appropriate lubricant and O-ring cloth.

Degradation

Any form of high-power light can harm an O-ring. When this happens, there may be a discoloration of the O-ring or a blotchy appearance as seen in the instance underneath. This occurs because of an interplay between the cloth inside the O-ring and the wavelengths of the light resulting in cracking of the O-ring and leakage.

Replacements

A fundamental rule for all mechanical components is to have replacements available. In the case of O-rings, they need to be carefully saved at room temperature and faraway from ultraviolet or solar mild, that can damage the O-ring‘s outer layer.

Abrasions

One of the most not unusual damages to O-ring seal surfaces is abrasion that breaks the seal on applications. The rubbing between the ring and housing heats the O-ring floor, which increases friction and modifies traits of the O-ring’s composition. The result of the boom in friction due to abrasions results in wear and tear at the O-ring as well as the formation of lacerations on its surface.

The effects of abrasions can be averted with the software of a lubricant that can sluggish the deterioration. Since abrasive damage takes place on best one facet of an O-ring, it is easy to spot and deal with.

Industrial Uses for O-Rings

The records of O-ring is intently related to the improvement of the vulcanization of rubber. The first O-rings were used completely as sealants for pistons and cylinders, a use this is still popular nowadays. During the Second World War, the discovery of new uses for O-rings made them an crucial a part of the conflict effort.

The business use of O-rings has grown unexpectedly as new makes use of are usually being located. From dental programs to sealing the lenses of cameras, O-rings may be found in a huge variety of industrial packages.

Transportation

Buses, vans, and motors depend upon O-rings for sealing the various sorts of fluids which might be a part of those systems. The exceptional types of fluids located in vehicles include fuels, refrigerants, and lubricating oil, that have variations in temperature and the rate at which they are used. Braking systems and lubricants for engines and transmissions depend on O-rings as a sealant and preventative for leaks.

Aerospace

O-rings are extraordinarily important for the construction of aircraft on the grounds that they shield jet engines from hot temperature changes and unsafe conditions. Thousands of O-rings are used in industrial aircraft with every one designed to perform a specialised characteristic, which includes adapting to high and coffee stress situations, aggressive lubricants and fluids, and radical temperature changes.

Changes in aircraft layout have made it vital to develop new O-ring compositions to satisfy the growing demand of the brand new situations. Recent designs have raised the working temperatures of O-earrings to over 275°F with greater durable compounds being perfected.

Medical

The United States Pharmacopeia (USP) units standards for materials used by the fitness and pharmaceutical industries. The ordinary use for O-ring is to shape a seal for fluids and gases that may have radical temperature and strain changes. Though these two features are part of the scientific use of O-rings, a further layer of requirements are introduced due to the need for sanitary conditions and cleanliness.

Silicone elastomers are used for pumps, valves, pipe work, couplings, response vessels, and biomatter packing containers are capable of face up to a wide range of media and pharmaceutical components (APIs) as well as be able to undergo aggressive cleansing and sterilizing. A foremost thing for medical O-rings is the ever growing regulations and hygiene standards from the Food and Drug Administration (FDA), United States Pharmacopeia – Class VI (USP Class VI), 3-A Sanitary standards, and Good Manufacturing Practice (GMP).

Electronics

In the electronics industry, O-rings are used for electromagnetic interference (EMI) shielding the use of elastomers produced to face up to various ohms from 7 cm to 0.002 cm. These in particular designed O-rings are utilized by telecommunications, the military, and for client and business electronics. They offer a conductive interface for a wide type of packages and come in a size to in shape any situations.

Food

Silicone O-ring for the meals industry had been permitted via the FDA. Much like silicone O-rings for the scientific enterprise, meals enterprise ones ought to follow the equal requirements that practice to any fabric that comes in contact with food. The FDA has a “White List” in Code of Federal Regulations – title 21, segment 177.2600 that outlines the necessities. The majority of the substances indexed are designed for excessive compression because of the challenge placed on curing materials.

Oil

O-ring within the petroleum, oil, and fuel industries are crucial elements of the exploration, refining, and transportation of oil products. The fundamental task for use of O-ring in the oil enterprise is the unforgiving situations below which they need to perform considering mining and extracting gas products is commonly done in harsh environments. The specifically designed O-rings have to meet all the regular conditions of temperature and strain however at tons higher requirements than is found in other industries.

Plumbing

There are a extensive type of O-rings made for the plumbing industry that are available in one-of-a-kind sizes, gauges, and designs. Typical O-rings for plumbing programs are product of NBR and can be determined in duct work and pipe furniture in addition to getting used as seals around faucets and fittings. The essential use of O-rings in plumbing is in push match fittings, the part of a pipe connection that calls for a seal to save you water leakage. It is located with a low insertion pressure and lets in the fitting to rotate. NBR O-rings are an critical factor in piping and water structures.

Scuba Diving

O-ring are a crucial and important a part of deep water diving. They provide a seal for underwater cameras, regulators, lights, and tank valves. The primary reason of scuba diving O-rings is their capacity to resist water stress and prevent leaks. In the case of deep water diving, O-ring are a life saving factor that protects the divers air deliver and water from leaking into gadget and suits.

Dentistry

In dentistry, silicone O-rings are used for dental implants, in which the O-ring is placed over the ball that secures the dental implant in vicinity. In figuring out the precise length O-ring for the software, the ball has to be measured to determine what size O-ring will fit over the ball however be stable enough to healthy inside the groove. Unlike in the beyond whilst dental implants were secured with a shape of paste or glue, present day implants have a permanently positioned ball that holds the implant in area.

The silicone O-rings, in this situation, function a buffer or help for the implant in order that it does not rub in opposition to the gum and motive infection.

Related FAQ’s

What is the purpose of O-rings?

Answer: The foremost purpose of an O-ring is to prevent fluid or air from escaping because it acts as a sealing device. When the ring is squeezed between surfaces, it takes up the clearance which prevents any fluid or air from being launched.

How do O-rings prevent leaks?

Answer: An O-ring prevents leaks by creating a long-lasting, moisture-resistant seal that locks the pressurized fuel and water interior of a machine. O-ring seal by being compressed among joined fittings, stopping any air or outdoor moisture from coming into the closed device.

What is the principle of O-ring?

Answer: The tendency of an O-ring to go back to its original shape while the move section is deflected is the fundamental cause of why O-rings make brilliant seals. The squeeze or rate of compression is a primary consideration in O-ring seal design.

What are O-rings made from?

Answer: O-ring manufacture usually is predicated on techniques like compression, transfer or injection molding, machining, or extrusion. There are a wide variety of high-overall performance materials used in the production of o-jewelry, ranging from nitrile and silicone rubber to fluorocarbons, metals, and extra.

Can O-rings be flat?

Answer: Because they’ve corners, flat O-rings may be used in addition to spherical O-earrings to seal off spaces in which the previous cannot. For example, as flat O-rings have a larger floor location and offer better coverage whilst screwed, they can be employed as a seal among an automobile’s oil filter out and oil housing.

Are O-rings hollow or solid?

Answer: The cloth from which an O-Ring is made is mostly an elastomer. For this motive, the O-Ring is likewise referred to as the rubber O-Ring or rubber rings. O-earrings can also be manufactured in LSR, different thermoplastic substances, FKM (Viton O-ring), and in metallic, each stable and hollow.

What’s the best way to store O-rings?

Answer: Temperature – O-rings need to be saved underneath 100F (38C) and saved far from direct daylight, and resources of warmth (radiators, heaters, boilers), and above 59F (15C). Humidity – Relative Humidity will be such the fluctuations in ambient temperature do no longer bring about condensation

When should you replace O-rings?

Answer: O-rings need to be replaced each years, or if after inspection it’s miles decided that the seal is broken.

Do O-rings need to be exact size?

Answer: One critical consideration you need to maintain in thoughts whilst sizing an O-ring is tolerance. Due to manufacturing boundaries, there’ll constantly be a few variance inside the O-ring’s dimensions. For example, an O-ring size of 0.103 with a tolerance of ± 0.003′, the move-phase can degree between 0.A hundred” and 0.106”.

Can I reuse an O-ring?

Answer: In many cases an O-ring can be reused, a bonus over non-elastic flat seals and overwhelm-kind gaskets.

How are o-rings labeled?

Answer: Sizes. Metric O-earrings are typically defined with the aid of the internal size x the cross phase. Typical component number for a metric O-ring – ID x CS (material)

Conclusion

We hope that we have cleared all yours questions about O-ring. If you have any queries about the “O-rings“ you can contact directly in my contact us page. Thanks for reading.

Related Post: