Introduction

This blog will take an in-depth look at Hydraulic and Pneumatic. The blog will bring more detail on topics such as:

- What Is Hydraulic And Pneumatic?

- How Do Hydraulic And Pneumatic Systems Work?

- Difference Between Hydraulic And Pneumatic

- Hydraulics VS Pneumatics

- Applications Hydraulics and Pneumatics

- Examples Of Hydraulics And Pneumatics

- Related FAQ’S

- And Much More…

What Is Hydraulic And Pneumatic?

Hydraulics and pneumatics play an important role in many different applications today, from industrial applications to autonomous devices that rely on fluid power to operate. But what do these two words mean and how are they different? This comprehensive guide delves into the world of hydraulic and pneumatic systems, explaining everything you need to know about their operation and use.

By definition, hydraulics refers to the use of fluids (usually oil) to transfer power within a system or machine. Pneumatic science, on the other hand, applies to systems that rely on wind to do the same thing.

In general, the fluid in both hydraulic and pneumatic systems is pressurized to store energy. The stored energy, and depending on the required task, can then be used to perform one of the following tasks.

- Raise a load

- Power a machine

- Work a lever

- Create a push

- For traction

- In a bigger range of automation processes

A hydraulic or pneumatic device can also be a small device that you hold in the palm of your hand, or it can be a large installation that can move very large loads After their meaning let’s look at how hydraulic and pneumatic powered systems generate movement.

How Do Hydraulic And Pneumatic Systems Work?

Hydraulic and pneumatic systems work by using pressurized fluid to transmit power or force. This generally involves forcing the fluid through various components to do useful work. To put that in perspective, here’s more about using fluids to transfer force.

Principles Of Hydraulics And Pneumatics

The work of hydrology and pneumatics is based on the principle of pressure transmission in liquids (liquids and gases). When a fluid is confined in space and under pressure, its force spreads in all directions. As a result, this force can be controlled (or multiplied) and used to create linear motion or rotational motion.

This can then be used to press items or perform other processing. Power transmission using fluids offers these advantages:

1- High power-to-weight ratio, especially when using fluids

2- Spark-free electrical conduction

3- Unlike electrical systems, no overheating problems

4- Ability to support multifunctional control actions

5- Without gears or chains Reduced machine complexity or belts

6- Smooth operation that is free from vibration

7- Reduced wear of parts

8- Quiet parts when using oil and other liquids

Difference Between Hydraulic And Pneumatic

The question of whether to use hydrology or pneumatics depends on a variety of factors. In most cases, application requirements regarding weight, required speed, cost, load quantity, accuracy level, and other considerations dictate the type of technology to use.

Hydraulic Systems

- If large loads have to be moved, your project will benefit greatly from the immense power of hydrology.

- Hydraulic is a good choice for greater operating accuracy.

- If quiet operation is also required, as these systems are almost silent. However, hydrologic systems are also more bulky and require more frequent maintenance.

Pneumatic Systems

- Pneumatic systems are best suited for applications that require high levels of cleaning or sanitation. That’s because they aren’t prone to spreading.

- Wind is also freely available and costs nothing, making pneumatic science a more cost-effective option.

- A pneumatic device will also not require storing spent fluid, as the gas can be safely discharged into the air.

- Hydraulic systems are slow. If your application requires fact-acting operators, pneumatic science will be your best choice.

- These systems are also lightweight and very few products or devices can be manufactured

- You can safely use pneumatic science in environments where sparks are prone to fire, such as electrical systems.

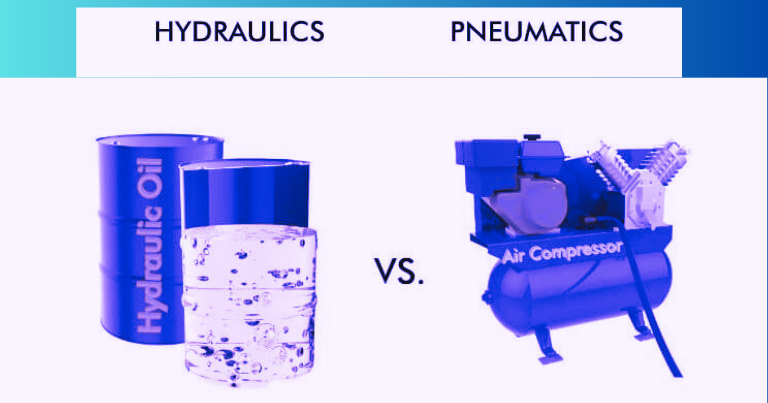

Hydraulics VS Pneumatics

Both hydraulics and pneumatics rely on the power of pressurized fluid to operate. But there are also notable differences between the two, and this should inform your decision when choosing your project. With that in mind, here are the differences and similarities between hydrology and pneumatics in more detail.

Similarities between Hydraulics and Pneumatics

The hydraulic and pneumatic systems are similar in a few ways. First, they harness the power of the compressed liquid. In other words, both systems are fluid-based and similar in principle of operation.

Another similarity is that the two systems require the use of various similar components to work: parts to pressurize the fluid, prepare and disperse the fluid, valves to control the flow, and actuators energy to mechanize the flow. In terms of application, systems that rely on hydrology and pneumatics are used in many of the same settings, with both offering almost the same advantages These include construction, manufacturing, and automotive.

Hydraulics and Pneumatics Difference

Despite the dependence on fluid energy to produce motion, there are notable differences between the two systems. The main difference between hydraulics and pneumatics is the type of fluid (or medium) each uses to transfer power. Aqueous means a liquid is being used.

This is usually petroleum-based oil or even water. These liquids are barely compressible, which means that their volume will not change noticeably under pressure. The result is that the application of force can increase their pressure tremendously. Pneumatic systems, on the other hand, rely on compressed air (such as gas or an inert gas like nitrogen) to operate.

Unlike fluids used in liquid-based systems, air is compressible. Despite providing faster speeds, it means less energy compared to liquid-based systems. It also means low accuracy.

Applications Hydraulics and Pneumatics

The applications of hydraulics and pneumatics are extensive and sundry. In other phrases, their use is sort of endless. Here, we’ve simplest listed a number of the maximum common of those make use of nowadays.

1. Manufacturing Industry:

Hydraulic and gasoline-operated systems are used to execute one-of-a-kind industrial procedures, from people who require simple actuators to those who involve complex automation.

2. Power Tools:

Today, hydraulic and pneumatic tools make responsibilities simpler to carry out. These encompass electricity tools like pneumatic drills and hammers or air cars.

3. Automotive Applications:

In the automotive zone, hydraulic and pneumatic circuits shape the premise of many systems, from brakes and shocks to guidance mechanisms.

4. Mining and Construction:

The mining and production enterprise benefits from the use of hydraulic structures. These are typically visible in heavy-responsibility machines along with excavation gadgets.

5. Aerospace:

Hydraulics and pneumatics assist carry out vital capabilities in aircraft structures, from landing equipment and brakes to other structures.

Examples Of Hydraulics And Pneumatics

Today, hydraulic and pneumatic gadgets are being used in simply every enterprise. This can vary from simple gadgets that use a single, linear actuator to huge multi-actuation systems. Common examples for every technique of transmitting fluid force are listed underneath:

Hydraulics Examples:

Business automation and different systems, heavy-obligation lifts, excavation device, car braking and guidance additives, plane elements, and different structures in which large forces and higher running precision ranges are necessary requirements.

Pneumatics Examples:

Industrial actuators to transport or keep merchandise, power gear like air hammers and pneumatic drills or wrenches, actuators for switching electric circuits, and different mild applications that require fast-acting and safe or clean mechanisms.

Related FAQ’S

What is hydraulic and pneumatic?

Answer: Pneumatics use without problems-compressible gasoline like air or pure fuel. Meanwhile, hydraulics utilize quite incompressible liquid media like mineral oil, ethylene glycol, water, synthetic sorts, or excessive temperature hearth-resistant fluids to make energy transmission viable.

How do hydraulics work?

Answer: The reservoir holds hydraulic fluid. The hydraulic pump pushes the fluid through the system and converts mechanical power into hydraulic fluid energy. The valves manipulate the glide of the liquid and relieve immoderate stress from the gadget if wanted. The hydraulic cylinder converts power again into mechanical power.

Why can we use pneumatics?

Answer: Pneumatics is a simple and reliable manner to make matters circulate, simply by way of the use of easy, dry air. Pneumatic systems use this compressed air to create mechanical motion and power applications to ‘do paintings’ in manufacturing facility automation structures.

Does hydraulics use air?

Answer: Pneumatics use easily compressible fuel like air or pure fuel. Meanwhile, hydraulics utilize surprisingly incompressible liquid media like mineral oil, ethylene glycol, water, synthetic sorts, or excessive temperature hearth-resistant fluids to make electricity transmission feasible.

Which is more powerful hydraulic or pneumatic?

Answer: In a nutshell, hydraulic systems are bigger and slower, but provide better precision and more strength, while pneumatic systems are better acceptable for packages requiring quicker, extra compact structures with lesser pressure and precision.

Conclusion

Today, hydraulics and pneumatics are popular technologies. Each type has its place in different industries, depending on the tasks required. When choosing whether to use a liquid or pneumatic system, be sure to know the advantages and limitations of each. I hope this blog has provided you with in-depth information about both technologies, including their many uses.