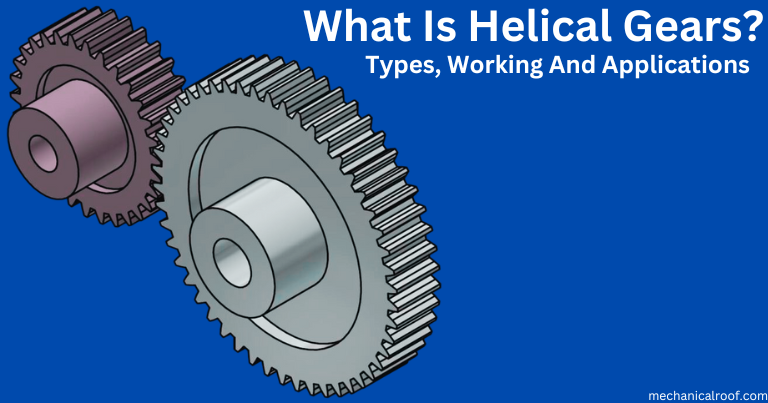

What Are Helical Gears?

Helical Gears are a special type of simple system that controls the strength and direction of force. A gearbox includes several gears which can be joined and linked via tooth. These gears switch energy from one thing of the system to any other. Modern business equipment gears demand high best helical gears and are used in maximum system constructing, production and creation machines.

The important purpose of helical gears as power transmission gadgets is to increase the torque and reduce the velocity among rotating shafts. They can be broadly divided into two types: gears that switch mechanical strength among parallel parts, and crossed-axis gears that switch strength among non-parallel components. Their functions and benefits are comparable to spur gears, however spur gears may be preferred whilst better speeds are required.

Helical gears are cylindrical gears with spirally curved teeth. These enamel are arranged at an angle, referred to as the helix attitude, relative to the gear axis. On common, helical gears have the identical involute teeth shape as spur gears, even if they may be cut. When properly designed, helical gears could have a bigger standard contact ratio, decreasing vibration and noise. Helical gears have more potent enamel and better load capacity than spur gears. Modular layout and manufacturing of transmission helical gears gives several technical and performance advantages because of the high interchangeability of additives and subassemblies. This permits for value-effective builds whilst keeping the highest levels of component integrity.

Types Of Helical Gears

The forces required to overcome the axial thrust can be neutralized or balanced with the aid of double helical gears. The complete cease face is split into same elements with contrary inclinations and the identical helix attitude. As the axial thrust forces cancel every different out, the forces stay inside the gear and are not transmitted to the bearings. These gears consequently have the benefit of high load capacity and dependable transmission. Due to their benefits, double helical gears are widely utilized in electricity transmission in fuel generators, turbines, high movers, pumps, fanatics, compressors, and many others. In ships and production equipment.

Specialized generators are commonly used to manufacture huge helical gears. However, due to the fact the enamel association limits the machining of the gears, engineers ought to very precisely manipulate the section difference of drawing near gears. The invention of gadget gear with many manage axes and a couple of capabilities made machines with complicated geometries feasible.

This improvement manner turned into proposed as a method for manufacturing bevel gears.

Many unmarried and double helical gears with huge enamel widths require helix attitude adjustment to make amends for enamel bending and twisting because of working hundreds. These are deliberately cut otherwise so that after the layout load is carried out at some stage in adjustment, the helix angles of the two mating gears are the equal.

Herringbone Gear

Herringbone gears are a special form of double helical equipment. Herringbone gears have two units of gears on one equipment, one on the right and one at the left. With sets of gears, the thrust of one set cancels the thrust of the alternative set. When you examine this tools from above, the spiral grooves resemble a V, growing a herringbone pattern. Due to this pattern, herringbone gears do not generate any additional axial load.

These gears have the benefit that they are able to transmit strength quietly, smoothly and at higher speeds because or greater enamel constantly mesh concurrently. In addition, they have a bonus over helical gears due to the fact the side thrust of every half is balanced by means of the alternative half. Herringbone gears may be used for torque gears with out the want for massive thrust bearings. Double helical planetary tools sets are therefore widely utilized in heavy excessive-velocity mechanical transmissions, in particular in marine generators and internal combustion engines.

Helical Rack and Pinion

A special sort of linear actuator called a helical rack and pinion converts the rotary motion of a round pinion into the linear movement of a rack.

In aggregate, they convert rotary movement into linear movement. When the pinion rotates, it drives the rack in a linear motion, while while the rack is moved in a linear motion, the pinion rotates.

Helical gears are quieter and more green than straight enamel gears. This is due to the more progressive way in which the enamel mesh with the rack. Helical gears can also deliver larger loads due to their longer contact duration. Also, rack and pinion have a shear aspect because of the opposite inclination of the helical gears on their parallel axes. Rack and pinion gears are most customarily used for automobile steerage. In a car, the rotational movement of the steerage wheel is converted into linear motion that turns the wheels.

Screw Gear

When engaged, the screw wheel does not exhibit a simple rotational movement, however a screwing movement, i.E. A permanent sliding of the lateral sides. As a end result, no point at the reference body of the helical wheel may be attributed to a basically rotational process, and the peripheral speed of the wheel is not identical at any factor. The reference body of a helical tools is a hyperboloid of revolution. The oblique line is turned around approximately the axis of rotation to create a hyperboloid. Screw gears are designed for medium speeds and torques, for instance in gadget device drives.

Helical wheels only produce low noise at moderate loads and pace degrees. To keep away from further wear resulting from frequent facet slippage, hypoid gear oil is generally used as a special lubricant for helical gears. However, the screw enamel additionally generate strong lateral forces, which should be absorbed with the aid of the precise bearing design.

In addition to the inclined axle arrangement and occasional-noise operation, helical wheels can also circulate axially within a highly extensive range without considerably affecting the electricity transmission. However, the usage of helical wheels reduces the transmission efficiency because of aspect slippage. Worm gears are an unusual kind of pass-hitch equipment. In comparison to standard screw gears, bug gears create a line touch between the teeth flanks and are consequently capable of transmit higher torques.

Helical Worm Gears

A helical worm equipment is a cylindrical object with an outside helical thread that meshes with and rotates any other tools. In this specific gear system, the bug or thread moves the tools. In numerous industries, computer virus gears are used to increase torque or whilst a enormous discount is required.

Helical bug gears often have high discount ratios and showcase self-locking. The trojan horse can rotate the tools, but the gear can not rotate the worm. The shallow bug perspective prevents friction from rotating the bug as the tools attempts to show. Helical bug gears are regularly utilized in high pace reducers. Conveyor structures are an example implementation wherein the locking mechanism additionally acts as a brake.

Differentials are torque loaded and operate with out loss of traction by way of dispensing torque throughout the tires and directing greater torque inside the maximum useful route. It works by using controlling the friction as a result of making use of torque to helical gears.

The worm wheel in this gearbox is of large diameter and is hooked up to the external tooth of the computer virus shaft. The non-intersecting perpendicular axis of the trojan horse wheel lets in the motor to generate rotational power. Intermeshing gears can cause a great speed discount as they interpenetrate, that is useful for a variety of applications. They also are frequently used to calibrate gear, elevators, and gates.

Helical computer virus gears also are perfect for conditions where shock loads are gift. Heavy responsibility device along with conveyors, packaging machines, shredders, and so forth. Fall into this class. Worm gears are known for low power, low pace packages, however they are able to most effective transmit low power.

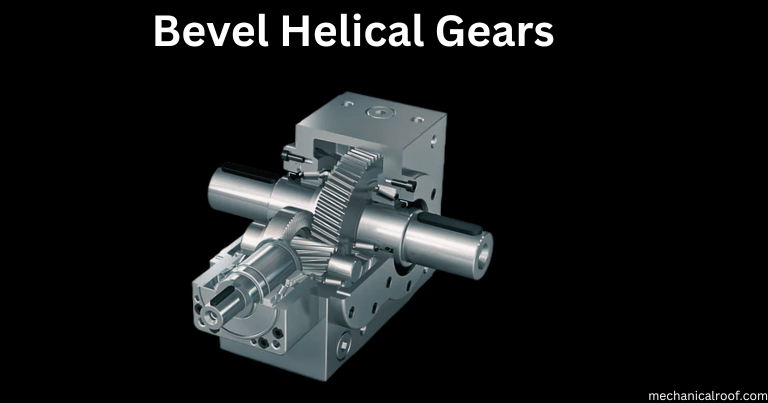

Bevel Helical Gears

lthough they can be designed to function at different angles, a bevel-helical gearbox is a proper-angle gearbox in which the gearbox output shaft rotates 90 degrees to the motor rotor shaft. The corrugations can be stable or hole. Bevel gears are available in on hand whilst the shaft wishes to rotate in a special course. Gearboxes with bevel-helical gears must be used for right-perspective geared motor applications that require excessive electricity density and excessive output torque. Bevel gears characteristic curved enamel surrounded through a tapered base on the cease of the device.

They create a strong and quiet movement via generating rotary motion between non-parallel shafts. As usually, helical enamel mesh with different helical tooth. Starting at one stop of the equipment, contact steadily increases for the duration of the length of every teeth.

Applications requiring high torque and excessive performance make those gears ideal. Bevel gears are also programmable. This industrial gearbox is widely used inside the concrete, metallic, plastic, automotive and mineral industries due to its power and durability. Bevel helical gearboxes are frequently used in business mixers, cable lifters and bags coping with systems. The meshing tooth allow for a strong transmission of strength and strength. Bevel helical gearboxes enable a huge sort of packages. They transmit strength greater correctly than bug gears. Bevel gears also offer high efficiency.

How Helical Gears Work?

Mechanical advantage, additionally called the ratio of output torque to enter torque in a system, is the essential precept in the back of helical gears. The tools ratio, or the ratio of the rate of the final tools to the speed of the first tools in a transmission, determines the mechanical advantage of the gears. In gearboxes, the regulation of conservation of electricity plays an crucial function in this regard. This idea can be simplified when analyzing a transmission by means of looking at the energy saved by way of the device. Furthermore, the analysis relates the angular pace of a gear to the torque of the equipment.

The unique tooth of a helical tools are located at a selected attitude to the shaft and tools surface. When two tooth meet in a helical tools gadget, the initial touch point is at one stop of the enamel, and as the gears rotate, the contact steadily widens till the two teeth are absolutely meshed. Because a couple of teeth are in touch for the duration of operation, the gears can withstand greater stresses.

This graduated meshing design distributes the weight among the enamel, so helical gears rotate quieter and smoother than spur gears. For this reason, helical gears are used in almost all car transmissions. In addition, helical gears have curved teeth, so they’re arranged offset. H. They ought to be stacked in a zigzag or staggered role. The tooth of the subsequent tools are arranged in a exceptional route than the tooth of the first tools so they can mesh.

But the sliding touch among the tooth resulting from the inclination angle of the tooth also generates axial forces and heat, reducing efficiency. Because the tooth of helical gears are angled, they place an axial load at the gears as they mesh. Helical gears have bearings that aid the rotation and might face up to this axial pressure. Inside the equipment, bearings help the rotating shaft.

Helical gears require thrust or roller bearings, which are frequently large and extra highly-priced than the obvious bearings used with spur gears due to the fact they have to face up to both radial and axial forces. The significance of the tangent to the helix perspective determines how the axial force varies. Helix angles are typically restrained to 45 stages due to the axial forces that occur, but large helix angles provide faster and smoother motion.

Selecting a Gear Type

When choosing system for a project, crucial dimensions should be taken into consideration, together with: B. Number of tooth, part diameter, outside diameter, and middle distance. Generally, packages requiring excessive speeds, giant electricity transmission, or noise reduction require the use of helical gears. For this purpose, they’re utilized in maximum car transmissions.

Helical Gear Applications

Fast Moving Industries

Helical gears are best for high speed applications as they revel in much less put on and friction compared to different gears, yet have a massive electricity transmission capability.

Pumps with Helical Gears

The layout of helical gears will increase the overlap of next discharges from the spacing among the tooth compared to the herringbone arrangement. Thus, the output float charge is greater uniform. As a end result, higher capability gears can be synthetic with fewer big teeth with out compromising the easy flow.

Industrial Chemical

Centrifugal compressors and turbines are slowed down the usage of helical gears to attain the rated speed of motors and mills. For those gears to characteristic well, they have to be well cooled and lubricated.

Automotive

Automotive helical gears are greater long lasting than spur gears because they have got more meshing teeth, which creates a bigger floor vicinity that could help weight. This makes helical gears ideal for heavy-duty automobile packages together with transmission operations.

Manufacturing

The teeth on helical gears allow them to face up to axial forces with rotational or rotary motion. Therefore, those gears are recommended to be used in equipment that requires higher rotational speeds, transporting heavy hundreds, or in continuous operation.

Advantages Of Helical Gears

- The principal appeal of helical gears is that they may be quieter than other gears. They are in excessive call for amongst massive manufacturing organizations. They provide smoother and more managed gadget transitions and efficiently hose down vibrations and shocks.

- You must also bear in mind whether your mission calls for energy transmission among non-parallel shafts. Helical gears make this viable, but in some instances it could come at the rate of efficiency.

- The teeth of helical gears allow axial forces to face up to rotational or rotary motion. Therefore, these gears are recommended to be used in machines that require high speed rotation, transporting huge amounts of products, or non-stop operation.

- Construction tasks and heavy machinery centers frequently use this sort of system. This is due to the fact helical gears can cope with larger torque shifts than different forms of gears. This is completed way to nicely-balanced and properly-designed gears, making them best for these demanding responsibilities.

- A final benefit of helical gears over spur gears is energy. Because helical gears are arranged at an perspective and are correctly larger, they are able to resist more masses than spur gears. Helical gears offer more electricity for the identical teeth length and corresponding width.

- Helical gears are bendy yet durable. Depending on the intended use of the gadget, the shaft connections for those gears can be either parallel or perpendicular. These permit machines to be adapted to specific necessities, as a consequence maximizing productivity.

- The car industry can use these gears to transmit strength and motion among proper perspective or parallel shafts.

Disadvantages Of Helical Gears

- Due to the helix attitude of helical gears, whilst a pair of helical gears mesh collectively, they generate axial thrust masses. Therefore, transmission designers ought to use bearings which could withstand and accommodate this load.

- With helical gears, the meshing of the gears creates a sliding movement, which generates extra heat than spur gears. Therefore, helical gears require high great lubricants.

- The performance of a matched pair of helical gears is less than that of a matched pair of spur gears of the identical size.

- Operating a helical gearbox incurs extra power losses than running a spur gearbox.

- The production and design prices of helical gears are higher than those of spur gears.