What Is a Wire Rope Assembly?

A Wire Rope kit includes a wire rope and quit fittings, clamps or lanyards attached to various sections of the cord rope that can be used to hoist, raise or flow masses. Different varieties of kits are designed for a variety of lifting applications, from small gadget to positioning elements for upkeep to supporting suspension bridges.

The key to a wire rope set is the kind of wire rope, which relies upon on the development and how the cables are prepare. A unmarried cord does now not have the power to withstand a load, however while multiple wires are twisted together and twisted together, they emerge as a sturdy lifting tool that can resist heavy loads.

Types of Wire Rope Assemblies

Different forms of wire rope assemblies are designed for precise applications and are specifically constructed to raise precise masses. Wire rope assemblies are warmness and abrasion resistant, acting nicely under all situations. The key with cord rope assemblies is to pick the proper assembly on your software, as selecting an assembly with a decrease load capability can result in software errors.

Wire rope comes in a number of thicknesses and metals, every thickness determines its load capacity. Manufacturers provide clean and concise records and personalised support on cord rope assemblies.

Single Strand Wire Rope Sling

Single strand cord rope sling is a common sort of wire rope assembly utilized in lifting and rigging packages. Wire rope slings are connected to lifting hooks or different attachment factors and used to boost heavy hundreds including machinery and creation substances. Single strand wire rope slings can be made from a whole lot of cord rope substances together with galvanized or chrome steel.

Multi-Strand Wire Rope Sling

Multi-Strand Wire Rope Sling is much like a unmarried strand sling, but has more than one strands or branches attached to at least one lifting point. This design improves load distribution and will increase the lifting capability of the entire assembly. Multi-strand wire rope slings may be made from loads of substances and come in a lot of configurations relying on the unique lifting utility

Wire Rope Lines

wire rope traces are used to stable gear, system, or employees at elevated positions inclusive of on scaffolding or construction websites. Typically crafted from galvanized or chrome steel wire rope, they’re designed to hold heavy loads and prevent gadget and gear from falling. Wire rope strains may be custom designed to precise lengths and attachment factors, making them versatile and adaptable for a number of applications.

Cable Railings

cable railings are a type of cord rope assembly normally used on residential and industrial production web sites. They are synthetic by attaching horizontal or vertical wire ropes to a supporting body or shape to provide a secure and durable railing gadget for balconies, staircases and different expanded places. Cable railings may be made from stainless steel or other substances and custom designed to fulfill unique layout desires.

Guyline Assemblies

guyline assemblies are used to provide stability and aid to tall structures such as transmission towers and antenna towers. They are made via attaching wire ropes to anchor points at the floor and the supported structure, creating a tensioned machine which can withstand wind and different forces. Guyline assemblies can be manufactured from a variety of wire rope substances and are generally designed and hooked up by using experienced specialists.

Control Cables

Control cables are utilized in a number of programs to transmit motion or force among two factors. They are usually manufactured from a aggregate of wire rope and a flexible protecting tube, which protects the wire rope from outside damage and maintains its strength and versatility. Control cables can be used in a number of programs inclusive of business equipment, automotive systems, marine system, and so forth.

Winch Rope

Winch Rope is a sort of cord rope meeting commonly used in the marine, creation and transportation industries. They are designed to withstand heavy loads and provide dependable pulling energy for winches and other towing structures. Winch ropes are crafted from numerous substances, along with galvanized or stainless steel wire rope, and are commonly equipped with eye hooks or other attachment points.

Sugarcane Cable

sugarcane cable is a type of wire rope assembly used inside the sugarcane harvesting industry. It is made by attaching cord rope to harvesters or tractors and is used to drag harvested sugarcane from the sector to the processing plant. Sugarcane cables are normally crafted from galvanized or stainless steel wire rope and are designed to resist the cruel conditions of the sugarcane field.

Wire Rope Sling Assembly

cord rope sling meeting is a versatile form of wire rope assembly used for lifting and rigging packages. They are made with the aid of forming cord rope into a sling and attaching it to a lifting hook or other attachment factor. Wire rope slings may be synthetic in quite a few configurations which include unmarried strand, multi-strand and infinite slings and may be custom designed to fit your specific lifting necessities.

Rope Hoists

Rope hoists are used in quite a few industrial and creation applications to boost and circulate heavy loads. Typically powered via an electric motor, they use wire rope to elevate and lower hundreds. Wire rope hoists can be custom designed to fit your precise lifting wishes and are to be had in a variety of capacities and configurations.

Wire Rope Catenary System

Wire rope catenary machine is used for numerous programs inclusive of catenary. A wire rope is suspended between factors and sags under its very own weight creating a curved shape known as a catenary. Wire rope overhead line systems are designed to resist heavy hundreds and provide reliable guide for land systems.

Each type of twine rope meeting is designed for a specific utility and synthetic using particular construction methods and substances. Understanding the exceptional types of twine rope assemblies and their packages allows users to pick out the right assembly for each software and ensure secure and green operation.

Components of a Wire Rope Assembly

A wire rope meeting combines a twinerope with quit fittings, clamps, and lanyards that are connected to the wire rope to shape a entire unit. End fittings, clamps, and fasteners are selected depending on the cause of the assembly. End fittings are positioned at any termination factor in which the wire rope is to be connected, inclusive of gadget or an item.

Hooks

hooks are used to attach a twine rope meeting to a load or anchor point. They are available a number of styles and sizes, such as eye hooks, clevis hooks, and grappling hooks, and are often crafted from substances consisting of alloy metallic and stainless steel.

Eyelet

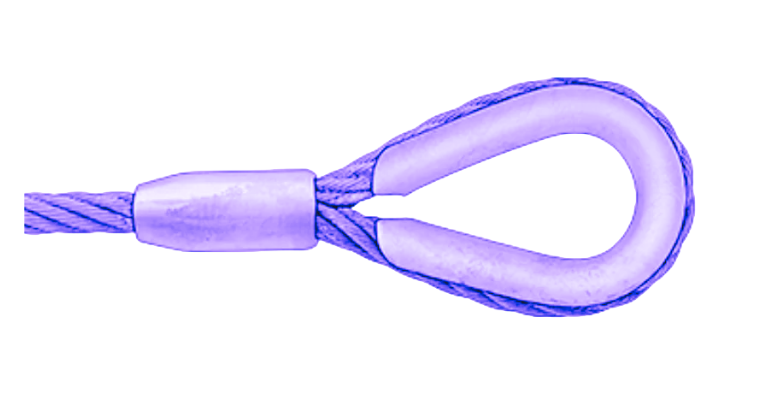

eyelet is basically a loop fashioned on the stop of a twine rope. It is used to create an attachment factor or to form a loop thru the rope itself. Eyelets can be made from substances like aluminum, stainless steel, carbon metallic and many others.

Thimble

thimble for wire rope assemblies paperwork an eyelet that boosts the loop or looped twine rope. It prevents fraying of the wire rope due to friction at the anchor point and increases the lifestyles of the wire rope assembly.

Thimbles are available in a variety of sizes and strengths and are presented in light responsibility and heavy obligation versions. Light duty thimbles are utilized in static programs no longer issue to widespread strain. Heavy duty thimbles have thicker coatings and are used in applications where wire rope assemblies must be often linked and disconnected.

The desire of wire rope thimble is determined by means of the environment in which it will be used. Stainless steel thimbles are used in corrosive and salt water environments. Galvanized metal, warm-dip galvanized metal, and grade 316 stainless steel are used within the manufacture of maximum wire rope thimbles.

Ferrule or Ferrule

Ferrules, additionally called ferrules, are used to connect cord ropes with the aid of crimping the ferrule onto the rope. This creates a strong and sturdy attachment point that can be used for numerous programs. Sleeves can be made from materials which include copper, aluminum, and stainless steel.

Shackles

Shackles are used to connect cord ropes or connect a cord rope to a load or anchor factor. They are available a variety of shapes and sizes, which includes D shackles, U shackles, and bolt shackles, and are often crafted from substances which include alloy steel or chrome steel.

The desire of give up fittings, fasteners, and clamps depends at the utility, surroundings, and requirements of the utility. For instance, a lifting sling may additionally connect to the weight the usage of a hook or shackle at one quit and a thimble or sleeve at the opposite give up to create a steady attachment point.

Wire Rope Clamps

Wire Rope Clamps are used to steady the twine rope after it’s been coiled. This additionally applies to wrapping the wire rope around a thimble. After the

twine rope is threaded thru the thimble, the loose end is connected to the rest of the twine rope the usage of a clamp. This clamp includes a U-bolt threaded on each ends, a bracket that slides over the threaded ends, and two bolts that hold the clamp in place.

Tension Screw or Tension Bolt

tension bolt has eye bolts at either quit of a metal frame, used to alter tension and reduce slack in the twine rope. The center of the anxiety screw is a metallic body that connects threaded fittings of diverse shapes like hook, jaw and eye.

Turnbuckle frame may be opened and closed, open turnbuckle is the traditional kind with visible threads at the cease connections. Closed tension screw or pipe anxiety screw has the threads enclosed within a closed frame giving a slimmer appearance. To tighten or loosen the tension screw, rotate the frame body.

Lock nuts can be placed on the threaded ends of fittings and tightened to prevent the cease fittings from loosening or coming free.

Applications of Wire Rope Assemblies

Transportation Industry

Wire rope assemblies are broadly used in the transportation industry for diverse purposes. For instance, twine rope assemblies are used in suspension bridges to support the bridge deck and distribute the load of site visitors. They also are used in elevators to raise and decrease the elevator automobile. Cable motors use cord rope assemblies to guide the cabin and ensure protection.

Construction Industry

In the construction enterprise, twine rope assemblies are utilized in various applications like crane cables, hoists, cable rail systems and so on. Crane cables are used to boost and flow heavy masses on production web sites even as hoists are used to raise and decrease employees and device. Cable railing systems make certain safety on balconies, staircases and at heights.

Oil and Gas Industry

Wire rope assemblies are used as drill pipes as they are able to face up to the pressures, stresses and temperatures of the drilling process. They are used in all areas of drilling together with deep water drilling offshore and onshore. They provide strong support, balance and exactly managed drilling.

Power Transmission

wire ropes are extensively used in power transmission packages like lifting, towing and conveying systems because of their excessive power, flexibility and sturdiness. They are regularly used in cranes, winches and cable motors to transmit energy and carry heavy masses over long distances.

Vehicle Construction

wire ropes are utilized in car creation for numerous programs like grab and brake structures, suspension structures and guidance systems. They provide dependable and durable performance even below high pressure and heavy masses making them an vital a part of secure and efficient operation of automobiles.

Mining

Wire rope slings are broadly used in the mining industry to lift and flow heavy loads like ores and equipment. twine rope slings are flexible and sturdy, making them best to be used in harsh mining environments.

Forestry

Wire ropes are used in forestry for lots of functions, along with felling and felling. For example, cord ropes can be used to boost and move tree trunks or for the managed felling of bushes.

Manufacturing

In manufacturing, cord ropes are used to raise and flow heavy gadgets, consisting of machines and products on meeting lines. These ropes are designed to provide stability and manipulate, allowing employees to move objects precisely and effectively.

Marine Industry

Wire rope assemblies are broadly used in the marine enterprise for numerous packages like mooring traces, anchor chains, winches etc. These assemblies are designed to resist harsh marine environments and withstand corrosion.

Benefits of Wire Rope Assemblies

Strength and Durability

cord rope and cord rope assemblies are regarded for their high electricity and durability, making them high-quality for lifting and transferring heavy hundreds. twinerope is likewise abrasion and corrosion resistant, resulting in an extended lifespan and decreased renovation prices.

Load Capacity

wire rope assemblies are designed to assist heavy masses, making them perfect for applications that require immoderate load capacity. By regulation, twine rope assemblies are marked with a Safe Working Load (SWL) rating. The load capability of twine rope assemblies can range from 1-2 hundreds to 100 hundreds relying on the configuration, rope type, and design.

Safety

wire rope assemblies are designed with protection in mind. They are engineered to face as much as immoderate stresses and heavy hundreds and undergo rigorous trying out to ensure they meet corporation standards for safety and overall performance. Additionally, twine rope assemblies are frequently used in packages wherein worker safety is vital, consisting of elevators and creation web sites.

Versatility

cord rope and cord rope assemblies can be used in a wide range of packages and industries, making them a flexible and adaptable answer. From production and mining to transportation and aerospace, twinerope assemblies may be customized to satisfy the unique desires of every company and application.

Cost Effectiveness

cord rope assemblies have a better initial price in assessment to other lifting and rigging answers, but have an extended provider existence and decrease renovation expenses over time. This makes twine rope assemblies a cost-effective solution for lots applications, especially folks who require immoderate load-bearing requirements.

Environmentally Friendly

cord rope assemblies are frequently crafted from recyclable substances, which means that a lower environmental impact compared to distinctive substances. Additionally, they’ll be designed to consume a great deal less electricity to operate than distinctive lifting and rigging solutions, making them a greater sustainable choice for plenty industries.

Benefits of cord rope assemblies consist of energy, sturdiness, load-bearing functionality, protection, versatility, value-effectiveness, and environmental friendliness. Proper twine rope assemblies make sure protection, performance and reliability while assembly sustainability desires. They’re a essential a part of a considerable form of programs, from lifting and transferring heavy masses to ensuring protection in manufacturing and transportation environments.