What Is A POP Rivet?

Pop rivets, additionally referred to as blind rivets, are a form of rivets. They are utilized in programs where there may be limited or no access to the rear aspect (blindside) of the parts to be joined.

Pop rivets are a unique kind of blind rivet designed to be hooked up from one aspect of a joint, making them extremely valuable for fabrication and assembly applications where you can’t access each side of the workpiece.

Pop rivets are an especially easy layout which includes a shank that is inserted right into a pre-drilled hole and a mandrel that suits through the shank. To install the rivet, the mandrel is pulled out with a blind riveting tool, which compresses the shank on the blind aspect of the workpiece, pulling the material collectively.

Once the joint is entire, the mandrel is snapped off at a pre-set nick for an easy end. These rivets are known as “pop rivets” because of the sound you pay attention to whilst the mandrel breaks off.

Installation is typically finished with an unmarried, mild pulling motion, however, the force required for installation relies upon the size of the rivet and its software. For simple maintenance or in case you simply want to add a few rivets, you could use a guide pop rivets tool.

For heavy packages that include manufacturing or production, you need to use a pneumatic or electric-powered pop riveting tool that gives greater pulling force.

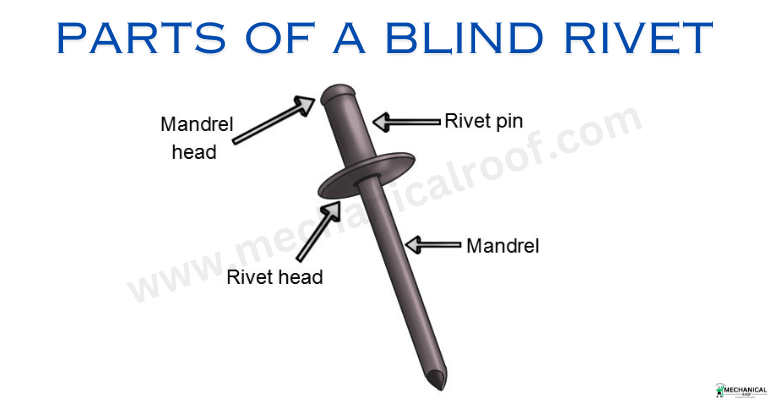

What Are The Parts Of A Blind Rivet?

Pop rivets, additionally known as blind rivets, are a type of rivet. They are used in applications wherein there’s a restricted – or no – right of entry to the rear aspect (blind side) of the components to be joined. Parts of father rivet

- Rivet pin: The pin is the principal body of the rivet so that you can slot through the portions of cloth being joined collectively.

- Rivet mandrel: The mandrel is slotted into the rivet gun when it’s miles fastened. The rivet gun pulls the mandrel partly through the pin (frame) of the rivet and deforms the pin to shape a 2nd head, after which snaps the mandrel off.

- Rivethead: The head will sit down on the outdoor of the fabric to stop the rivet from sliding out of the material.

- Rivet mandrel head: The mandrel head expands the frame of the rivet and then leaves itself buried in the rivet, creating a 2d head to steady and fix the portions being joined.

How Does POP Rivet Work?

Pop rivets include two elements. The first part is called the rivet body (also called the shell or hat) and the second detail is referred to as the mandrel (moreover called the stem).

In situations where access to both facets of a factor is confined, a hollow is first drilled through the elements to be joined. A pop rivet is then inserted through the drilled hole and the rivet frame is added into contact with the parts.

A rivet gun is located at the rivet and pulls the mandrel into the rivet body, inflicting it to expand and preserve the components to be joined. Once gripped, the mandrel snaps and holds the rivet permanently in location. This results in a localized connection.

What Are The Different Types Of Blind Rivets?

A blind rivet, once in a while called a pop rivet, has a hollow cylindrical pin (body) this is attached to the pinnacle. A mandrel, an extended, slender pin with a head, is going through the recess of the frame, with the head serving as a forestall at the other end of the frame to the rivet head.

Blind rivets are available with unique kinds of our bodies and heads. They are crafted from special substances.

1-Standard Blind Rivets

Standard blind rivets are typically used to stable metallic to metal. They have domed heads and simple our bodies. If you pull the mandrel in part via the rivet frame, the frame will make bigger at its “blind” stop, creating a second head that may be used to permanently be part of the substances collectively.

Standard rivets are utilized in some of industries along with automotive, creation, metals, electrical home equipment, boxes, fixtures, air con, and heating.

2-Peeled Blind Rivets

Peeled rivets provide a locking head with a larger diameter, providing them with a more bearing floor (underside of head). As the mandrel is drawn through, the frame expands, leaving the head in the form of a flower with four petals. This form of rivet is well suited to fastening metallic to softer substances.

The aspects (petals) of the rivet fold over, developing a head to fasten the substances together. Peeled rivets are ideal to be used in the automobile industry, and construction paintings (plasterboard, coatings, and insulation) and may be used on trailers, plastic components, electric appliances, and upholstery (padded overlaying on furnishings).

3-Multi-Grip Blind Rivets

Multi-grip rivets are just like trendy rivets but have indents located at the rivet frame. The indents expand and offer a couple of grips while the mandrel is pulled via the body. These rivets are for bonding metal to plastic, plastic within plastic.

The multiple grips on the body of the rivet are forced towards the fabric being riveted because the mandrel is pulled through. Multi-grip rivets are appropriate to be used in the car, production, and metal industries, and in electric home equipment, furniture, electronics, ladder manufacturing, and air conditioning and heating.

4-Grooved Blind Rivets

This sort of rivet has grooves around the frame that provide the rivet awesome gripping strength whilst installing softer materials consisting of plastic and wood. Grooved rivets are best for securing metallic to wood and steel to building materials including cement, brick, and timber.

The grooves on the rivet body are embedded within the material and hold it collectively almost like a screw. The hole it goes into doesn’t must be right through the cloth.

The tail of a grooved rivet will amplify inside the fabric because the mandrel is withdrawn, as opposed to forming a new head on the other facet of the fabric. The rivet grips the fabric with friction and now not with a second head, while the top at the alternative quit grips the item that is linked to the fabric.

Grooved rivets are quality for creation, metalworking, and furniture production, in addition to electrical device and injection, molded elements.

5-Sealed Blind Rivets

This form of blind rivet comes with a sealed quit. The mandrel head does now not protrude from the cease of the rivet like the different styles of blind rivets covered inside the sealed frame. Sealed rivets do not permit beverages to penetrate or leak and are used to secure metal to metal.

The head of the mandrel sits inside the body of the rivet even as the top of the rivet is sealed. This prevents liquid from coming into or exiting the factor. They are suitable to be used within the automobile, production, and metal industries. They can also be utilized in electric home equipment, boxes, fixtures, and aircon and heating systems.

6-Dome Head Blind Rivets

The dome head offers enough bearing floor for it for use to lock a lot of substances, besides extraordinarily clean and brittle materials consisting of plastic.

This is due to the fact this kind of head applies extra pressure closer to the hollow that has been drilled that could harm softer materials. The bearing floor is the touch among two substances. In this case, it’s miles the region beneath the top of the rivet which makes contact with the material being mounted.

7-Soft Set Blind Rivets

Soft rivets are same to conventional rivets. However, the body and mandrel are product of a softer metallic, which tends to be an aluminum alloy. The mandrel breaks off with plenty less force than other types of rivets so it applies the right amount of stress to fasten brittle materials without them turning into damaged.

These rivets are for use while fastening metal to plastic, metallic to wooden, metal to fiberglass, plastic to plastic, and metal or plastic to smooth materials with low resistance. The tender rivets may be utilized in furniture, packaging, plastic components, bins, plastic, and creation work.

8-Large Head Blind Rivets

The large head offers double the bearing vicinity of a dome head rivet. This gives brilliant resistance and is right for fastening brittle or smooth substances to rigid assist substances.

9-Blind Rivets Heads

As properly as being to be had in a number of body designs, blind rivets can also have one-of-a-kind forms of heads.

10-Countersunk Head Blind Rivets

A countersunk head suits into the material without the top protruding, preserving a flat floor.

Applications Of Blind Rivets

They are used to make high-electricity joints in a number of substances, along with metals, plastics, timber, and leather. Typically, the process is used for becoming a member of plastic or sheet metallic.

To enable pop rivets to meet the requirements of a wide type of packages, they’re available in lots of substances, which includes Steel, Stainless metal, Monel, Copper, Aluminium

Uses for Blind Rivets

- Attaching Hinges.

- Attaching Door Knobs, Drawer Pulls, and Handles.

- Building or Home Applications.

- Industrial Applications.

- Woodworking Applications.

Advantages Of Pop Rivets

- Being lighter than bolts/screws (depending on rivet fabric)

- Allowing for joining of parts whilst there may be confined rear get entry to

- Being cost powerful

- Being durable

- Lack of Aesthetic Finish

- Higher Structural Weight.

- Easy Inspection and Maintenance.

- Flexibility in Design.

Disadvantages Of Pop Rivets

- Protruding from the sheet steel surface, potentially growing a risk and decreasing aerodynamics

- Potential corrosion problems if the rivet cloth differs from the steel components to be joined

- Being tough to eliminate as soon as positioned

Related FAQ’s

1-How long should pop rivets be?

Answer: The period of a rivet is measured from the bottom of the head to the tip of the stem. The head itself isn’t always blanketed on this dimension. The duration of the rivet need to be same to the thickness of both items you are fastening, plus 1.Five times the diameter of the rivet’s stem.

2-What is a Pop Rivet and How Do They Work?

Answer: They are used to make excessive electricity joints in a number substances, consisting of metals, plastics, wood and leather. Typically, the approaches is used for becoming a member of plastic or sheet steel. To permit pop rivets to satisfy the necessities of a huge sort of packages, they may be to be had in many materials, along with: Steel.

3-Why are pop rivets good?

Answer: The first and maximum large benefit of pop rivets is that they enable you to rivet a material even if you cannot attain the again side of it. They have the additional advantages of being cheaper, and comparatively brief and clean to install, in comparison with options which includes welding.

4-How much can a pop rivet hold?

Answer: McMaster prices pop rivets in tensile energy as well as shear energy. A three/16″ aluminum blind pop rivet has a shear energy of 310lbs and a tensile power of 500lbs

5-What diameter rivet to use?

Answer: The rivet shank period has to be identical to the thickness of both layers you’re becoming a member of plus 1.Five instances the diameter of the rivet’s stem. The rivet shank diameter must be identical 3 times the thickest sheet being joined. That’s the minimum diameter.