Introduction

Also referred to as “little power flowers,” pistons are small however powerful components that play a important role in many mechanical systems, from vehicle engines to business pumps. But what exactly is a piston and the way does it work? Let’s find out.

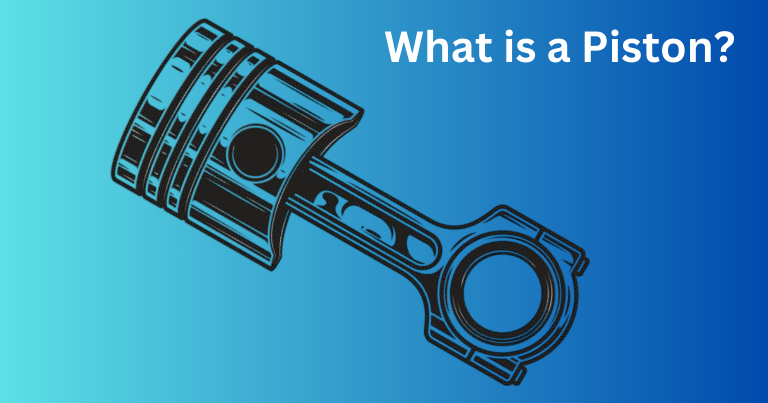

What is a Piston?

A piston is a component in piston engines, piston pumps, gasoline compressors, hydraulic cylinders, pneumatic cylinders, and different similar mechanisms.

It is the moving element housed within a cylinder and made hermetic with the aid of piston rings. In an engine, its task is to transfer the pressure of the increasing gases inside the cylinders via piston rods and/or connecting rods to the crankshaft.

The pistons are linked to connecting rods, which are related to the crankshaft. The pistons, connecting rods, and crankshaft paintings collectively to transform the up and down motion of the pistons into rotational movement that drives the wheels of the car.

Internal combustion engines have from 1 to 12 cylinders, with most automobiles having four, 6, or eight cylinders. They are also used in outside combustion engines, additionally known as steam engines, where steam created from boiling water drives a piston in an external cylinder.

Wankel engines haven’t any pistons, cylinders or valves, but a triangular rotating rotor. However, Wankel engines are now not produced. The closing became within the Mazda RX-eight, which ceased production in 2012.

In a 4-stroke engine (petrol or diesel), the consumption, compression, combustion and exhaust approaches take area on the piston crown, which causes the piston to transport up and down inside the cylinder, compressing the air-gas mixture, that’s then ignited by means of a spark plug.

The explosion pushes the piston down, growing exhaust gases that depart the engine through the exhaust device.

What are pistons made of?

Engine components ought to be long lasting for lengthy-time period use and light-weight to enhance performance.

Thus, pistons are typically manufactured from aluminum alloys, while piston earrings (normally which include a compression ring, wiper ring, and oil ring from the pinnacle) are fabricated from solid iron or metal.

The oil ring wipes oil from the cylinder walls because the piston moves, however through the years the oil ring and different rings put on out and oil can leak from the crankcase into the combustion chamber.

Excessive oil consumption and white smoke from the exhaust tailpipe imply worn piston jewelry.

Internal combustion engines can operate with a unmarried cylinder, i.E. One piston (motorcycles and fuel lawnmowers), or with as much as 12 pistons, even though maximum automobiles have 4 or six pistons.

Radial engines, normally utilized in propeller aircraft, have an bizarre wide variety of cylinders and pistons for smoother operation.

Pistons also are used in outside combustion engines, also referred to as steam engines, which contain heating water in a boiler and the use of the steam to strength a couple of pistons (usually in an outside cylinder) that pressure the wheels.

Parts of a piston

The piston, because the shifting part of the combustion chamber, is responsible for converting this launched electricity into mechanical paintings. The basic structure of a piston is a hole cylinder closed on one side with segments of piston crown, piston hub and piston skirt with ring phase.

Important Parts of Piston and Their Functions:

1. Piston Rings

Piston earrings hold the compression of gases between the piston and cylinder wall. Piston rings seal the cylinder so that the combustion gases generated for the duration of ignition do now not input the opening among the piston and cylinder.

A common car engine normally has 3 forms of piston jewelry:

- Compression ring: This is the top ring and is positioned closest to the combustion chamber. It is also known as the gas ring or pressure ring. The ring prevents the break out of combustion gases. The compression ring additionally enables in the switch of heat from the piston to the cylinder wall.

- Wiper ring is a piston ring with a conical floor that sits in an annular groove among the compression ring and the oil ring. The wiper ring serves to further seal the combustion chamber and wipe extra oil from the cylinder wall. The combustion gases that pass via the compression ring are stopped via the wiper ring.

- The oil ring is the piston ring inside the annular groove closest to the crankcase. The oil ring wipes extra oil off the cylinder wall at some stage in piston motion. The excess oil passes thru the hoop commencing and is back to the oil reservoir in the engine block.

2. Piston Skirt

Piston skirt is a cylindrical piece of cloth that suits over the circular segment of the piston. This element is typically made from forged iron because it’s miles put on-resistant and self-lubricating.

Blouse carries grooves for mounting the piston oil ring and compression ring. Piston skirts are available in plenty of patterns to fit specific applications.

There are major varieties of piston shirts:

- Full shirt: Also known as stable shirts, full shirts are tubular in form. They are commonly observed in huge car engines.

- Slipper skirt: This sort of piston skirt is used on motorcycle and a few car pistons. A part of the shirt is cut away, leaving best the back and front at the cylinder wall. This reduces weight and minimizes the touch region among the cylinder wall and the piston.

3. Piston Pins/Piston Pins

Piston pins are also called wrist pins or piston pins. They join the piston to the connecting rod and act as a connecting rod bearing that rotates as the piston actions.

In very early engine designs, along with steam-powered engines and many very huge desk bound or marine engines, the piston pin turned into positioned in a sliding crosshead that turned into related to the piston through a rod.

Piston pins are generally quick, solid hole rods made from a metallic alloy with high strength and hardness, and can be bodily cut loose both the connecting rod and the piston or crosshead.

Piston pin layout is a challenge, specifically in small, high-revving car engines. Piston pins must operate at some of the highest temperatures encountered within the engine and their vicinity makes them tough to lubricate. At the equal time they have to continue to be small and mild to fit inside the piston diameter and not increase the piston mass an excessive amount of.

The requirement of lightness and compactness necessitates small diameter rods which are subjected to high shear and bending masses and which revel in the best compressive loads of any bearing in the complete engine.

To clear up those problems, the cloth and manufacturing technique of the piston pin are some of the most stressful of all mechanical components in an inner combustion engine.

This gives upward thrust to the subsequent bolt kinds:

- Fixed/constant bolt: The bolt is attached to the piston hub through a thread. The piston rod rotates at the bolt.

- Semi-floating: The pin is attached to the primary connecting rod and the ends of the pin are loose to transport within the piston bearings and on the hub.

- Fully floating: In this kind of pin, the pin is not connected to the piston pin or connecting rod. Instead, it is held in region with the aid of a plug, clip or circlip attached to the piston boss. The bolt is allowed to swing on each the hub and the rod.

4. Piston Head/Piston Crown

The head of the piston, additionally referred to as the piston crown or dome, is its higher floor. It is the part that comes into touch with the combustion gases. This reasons it to warmness as much as very excessive temperatures. To save you melting, the piston head part is product of unique alloys, including steel alloys.

Piston heads generally have channels and cavities. This creates swirl and aids in combustion.

Different engines use special forms of piston heads. The motives for the variations vary. The preferred piston head design depends on many elements, inclusive of the anticipated performance and engine type.

5. Connecting Rod

A connecting rod, additionally called a connecting rod, is part of a piston engine that connects the piston to the crankshaft.

6. Piston Bearings

Bearings are components of the piston which might be positioned on the factors in which the pivoting movement takes location. Usually they are semi-circular pieces of metallic that fit into holes at those factors.

Piston bearings contain a cup on the large quit wherein the rod connects to the crankshaft. There is likewise a bearing at the small end where the rod connects to the piston.

Piston bearings are generally made of composite metals which includes lead-copper, silicon-aluminum, and so forth. Bearings are often coated to improve hardness and to take in the masses due to piston and connecting rod motion.

Types of Pistons

There are three sorts of pistons named after their shape: flat pistons, dome pistons, and disc pistons.

1. Flat Pistons

As simple as it can sound, flat pistons have a flat top. A flat piston has the smallest floor location. This lets in it to generate the maximum energy. This form of piston is best for efficient combustion.

Flat valves produce the maximum uniform flame distribution. The hassle with that is that a small combustion chamber can purpose excessive compression.

2. Disc Piston

Disc pistons gift the least issues to engineers, extra because of where they’re used than due to their homes.

It has the form of a plate with a mild upward curve at the outer edge. Typically poppet pistons are utilized in supercharged applications that do not require high carry camshafts or high compression ratios.

3. Dome Pistons

In comparison to plate pistons, those form a bubble in the middle just like the top of a stadium. This is finished to boom the floor place to be had on the pinnacle of the piston. The extra floor area, the much less compression there’s.

The higher the compression ratio, the greater energy is produced, however there may be an top limit to the performance of each combustion chamber. Reducing the compression ratio in this way essentially prevents the engine from falling aside.

Different Types of Pistons

Following are the Types of Pistons:

- Trunk pistons

- Crosshead pistons

- Slipper pistons

- Deflector pistons

- Racing Pistons

1. Trunk pistons

Plungers are long as compared to their diameter. They act as each the piston and the cylindrical crosshead. Because the connecting rod is at an attitude for most of its rotation, it additionally exerts a lateral pressure along the aspect of the piston against the cylinder wall. The lengthy piston contributes to this.

Plunger pistons have been a common piston layout since the early days of reciprocating internal combustion engines. They have been utilized in each gasoline and diesel engines, however lighter sliding pistons are now utilized in higher speed engines.

A exclusive feature of maximum plunger pistons, specially in diesel engines, is that they have a groove for an oil manipulate ring under the piston pin similarly to a ring among the piston pin and the piston crown.

The call “diving piston” comes from the “diving engine”, an early layout for marine steam engines.

To make it extra compact, it turned into the primary gadget to miss the piston rod with a separate crosshead that became not unusual in steam engines, and rather place the piston pin directly at the piston.

Otherwise, these pistons with piston rods bore little resemblance to piston rod pistons. They had very big diameters and have been double acting. Their “rod piston” turned into a thin cylinder installed in the center of the piston.

2. Crosshead Piston

In big gradual speed diesel engines, extra assist in opposition to lateral forces acting at the piston can be required. These engines normally use crosshead pistons.

The major piston has a large piston rod that runs from the piston to a 2nd smaller diameter piston. The main piston is chargeable for the fuel seal and carries the piston earrings.

The smaller piston is a simply mechanical manual. It operates in a small cylinder as an airframe guide and is also geared up with a piston pin.

Crosshead lubrication has blessings over trunk pistons because the lubricating oil isn’t always uncovered to the warmth of combustion. The oil isn’t always infected via combustion soot debris, isn’t always damaged down through warmness, and thinner, less viscous oils may be utilized.

The friction among the piston and the crosshead is simplest 1/2 that of the plunger. These pistons aren’t utilized in excessive speed engines due to the accelerated weight.

3. Slipper Piston

A slipper piston is a piston for a gasoline engine that is as small and light as possible.

In intense cases it’s miles reduced to just the piston crown and piston ring holder, leaving enough of the piston skirt to leave two webs to prevent the piston rocking backward and forward within the bore.

The facets of the piston skirt around the piston pin are decreased faraway from the cylinder wall.

Its most important purpose is to lessen the reciprocating mass to make the engine easier to stability and to allow better speeds. In racing programs, slipper piston shirts can be built to be very lightweight whilst maintaining the stiffness and power of a full shirt.

The reduced inertia also increases the mechanical performance of the engine. The forces required to boost up and decelerate the reciprocating elements create more friction among the piston and the cylinder walls than the fluid pressure on the piston head.

Another advantage is that the place of the shirt sliding up and down inside the cylinder is decreased by using half of, so friction with the cylinder partitions is barely decreased.

However, most of the friction is from the piston rings, the components certainly closest to it in the bore, and the walking surfaces of the piston pin, decreasing the benefit.

4. Deflector piston

Deflector pistons are utilized in crankcase-compressed two-stroke engines wherein the fuel waft inside the cylinder must be cautiously directed to make sure efficient scavenging.

In cross scavenging, the transfer (front to the cylinder) port and the exhaust port are located on directly contrary sides of the cylinder wall.

To prevent the incoming aggregate from flowing directly from one opening to the other, the piston has a raised rib at its base, the cause of that’s to direct the incoming mixture upwards around the combustion chamber.

Much attempt and plenty of piston crown designs went into growing progressed flushing structures. The crown evolved from a simple rib to a massive asymmetrical bulge, usually with a steeper surface at the inlet side and a greater sluggish curve on the opening side.

Nevertheless, pass-flash become now not as powerful as hoped; most engines now use schnoodle porting rather. This involves setting a couple of transfer ports on the perimeters of the cylinder so that the gasoline drift rotates approximately a vertical axis in preference to a horizontal one.

5. Racing Pistons

In racing engines, pistons generally have an awful lot higher power and stiffness than passenger car engines, and much decrease weight to reap the high engine speeds required in racing.

Piston Function:

The most essential tasks that the piston has to fulfil are:

• Power transmission to and from the working gasoline

• Variable restrict of the working area (cylinder)

• Sealing of the running space

• Straight guide rod at the relationship (plunger piston engine)

• Heat dissipation

• Support of gas trade with consumption and exhaust (4-stroke engine)

• Support of combination formation (with the aid of appropriate form of the piston surface on the combustion chamber facet)

• Controlled gasoline trade (in two-stroke engine)

• Guide of sealing factors (piston jewelry)

• Guide of the connecting rod (in top-set up connecting rod)

As the particular energy of the engine increases, the needs on the piston also growth. .

Piston Properties:

The piston have to be sturdy enough to withstand:

- The striking effect of combustion gas pressure,

- The fluctuating load and high temperature of fuel.

- The piston must:

- Be light in weight

- Be quiet in operation, and

- Be routinely stable.

- Light in weight,

- Reduces inertial losses and

- Changes in movement, decreasing the inertial masses on the bearings.

Piston Advantages:

The foremost advantages of piston are:

- Mechanical simplicity

- Flexibility and reliability

- Power to weight ratio

- Multi fuel functionality

- Low turbine running temperature

- Less vibration and noise

- Reduced preservation

- Easy piston beginning

- Very appropriate for waste heat recovery

- High drivability

- Low manufacturing cost

- Low NOx emissions

- Provides HCCI combustion technique

- Internal balance

- Modularity Disadvantages of

Piston Disadvantages:

- Poor gas financial system

- Stability of fuel deliver

- Poor component load performance

- High combustion charge

- Need for reduction gear