What Is A Hydraulic Ram Pump?

A hydraulic ram pump or hydrum is a rotating water pump driven by water power. It takes water with a “hydraulic head” (pressure) flow rate and produces a low flow with an increase in water head.

The device uses the water hammer power to create a pressure that allows the pump to raise the output level above the initial starting level water rams are sometimes used in remote areas where headwater energy sources are limited and more water is required to be delivered to the destination than to the destination In this case, it’s usually an advantage on the ram because it doesn’t need any external source of energy other than the flow of energy.

Working Of Hydraulic Ram Pump

Now we understand how the hydraulic ram pump actually works, step by step:

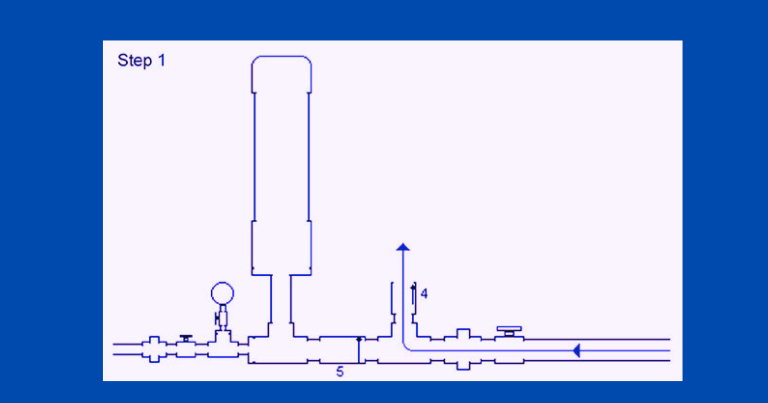

Step 1:

Water (blue arrow) begins to flow via the drive pipe and out of the “waste” valve that is initially opened. The water flows rapidly through the pipe and out of the waste valve.

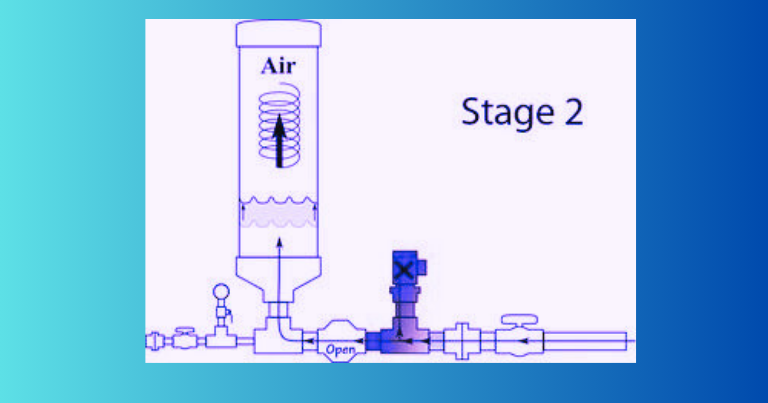

Step 2:

At some point, water passes through the waste valve so fast that it pushes the valve flap up and closes it. The water in the pipe was moving fast and had high motion, but both the weight and movement of the water stopped by closing the valve causing a high-pressure spike (red arrow) in the closed waste valve. The high-pressure gradient forces a fluid (blue arrow) through the check valve and into the pressure chamber. This increases the pressure in that room. The pressure “spike” in the pipe also begins to rise at the speed of the sound in the drive pipe (red arrow) coming from the waste valve and is released at the inlet of the conduction pipe.

Step 3:

When the high-pressure wave reaches the back of the drive pipe inlet, a “normal” pressure wave (green arrow) descends through the pipe back to the waste valve Depending on the back pressure check the valve still slightly open, allowing water to enter the pressure chamber can be.

Step 4:

Once the normal pressure wave reaches the waste valve, the low pressure (blue arrow) flows across the drive pipe, reducing the pressure on the valves and releasing the waste valve to open and close the check valve.

Step 5:

When the low wave reaches the drive pipe inlet, the normal pressure wave moves down the drive pipe into the valve. Because the discharge is high above the ram, the regular flow follows this pressure wave, and the next cycle begins.

Hydraulic Ram Pump Operation

Hydraulic ram pumps operate using pressure generated by shock waves of “water hammer”. Every object in motion has an inertial force. It takes energy to keep an object moving, it will also take energy to stop motion, and starting or stopping motion quickly will require more energy.

The fluid flowing in the pipe also has inertia (or strength) to resist sudden changes in velocity. Closing the valve slowly causes this inertia to decay over time, resulting in a small increase in pressure in the tube.

Closing the valve too quickly creates a pressure build-up or shock wave as the flow stops, which returns to the pipe – such as used at a railway station, where individual rail cars strike a front coupling in quick succession like brakes.

The faster the valve is closed, the larger the shock wave. Faster flow will also create a larger shock wave when the valve is closed because there is more inertia or movement involved. A longer tube will create more shock waves for the same reason.

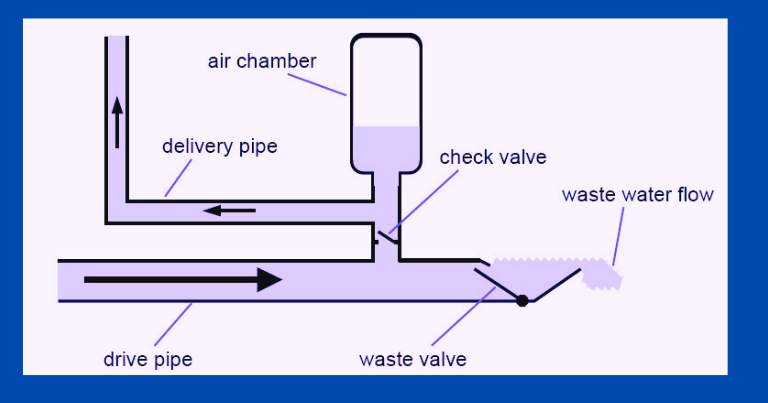

A hydraulic ram relies on a pressure-free flow of water in a pipe carried from a water source to a pump (called a “drive” pipe).

This flow is achieved by placing a hydraulic ram some distance below the water source and running a drive pipe from the water source to the pump The hydraulic ram uses two check valves, which are the only movable parts of a pump in the 19th century.

Hydraulic Ram Pump Efficiency

Basically energy efficiency is 60%, but up to 80% is possible. This should not be confused with the volume efficiency of the total amount of water supplied to the water received from the source. The water portion of the distribution system shall be reduced in proportion to the distribution head and supply head.

Thus, if the source is 2 m above the ram and the water level is raised 10 m above the ram, only 20% of the supplied water is available, the remaining 80% being discharged through the waste valve This formula assumes an energy efficiency of 100% .

Real water will be supplied by an efficient catalyst. In the above example, if the energy efficiency is 70%, the supply of water will be 70% within 20%, i.e. 14%.

Assuming a 2-to-1 supply head-to-distribution head ratio and 70% efficiency, the water supply would be 70% within 50%, ie. 35%. Very high delivery and delivery rates generally reduce energy efficiency. Lamb suppliers often provide tables that give the required numbers based on actual tests.

Starting Operation Of Hydraulic Ram Pump

A ram that has been reassigned or cycled should start automatically if the weight or spring pressure of the waste valve has been correctly adjusted, but it can be started more frequently e.g.

- If the waste valve is in the high (closed) position, it should be released by manually pushing it down to the open position.

- If the flow is sufficient, then it will cycle at least once.

- If he doesn’t cycle, push him down repeatedly until he cycles himself, usually with three or four hand cycles.

- When the ram leaves the waste valve in the floor (open) position, it must be manually lifted for as long as necessary to fill the supply pipe with water and allow any air bubbles to ascend the pipe to the source .

This can take some time, depending on the length and diameter of the pipe being supplied. It can then be started manually by pushing down a few times as described above. Having a valve on the distribution pipe in the ram makes it easier to start.

Close the valve until the lamb begins to cycle, then slowly open it to fill the feed pipe. If it opens too fast, the cycle will stop. Once the distribution pipe is full, the valve can be left open.

General Operation Problems

Insufficient water supply can be due to inadequate changes in the litter box, too little air in the pressure vessel, or simply trying to lift more water than the sheep can handle.

In winter, frost can damage the sheep, or cause a loss of air in the pressure vessel to put additional pressure on the walls. These failures will require welding or other repair procedures and possibly part replacement.

It is not uncommon for the operations ram to need to be rebooted from time to time. Cycling can stall because of improper adjustment of the waste valve, or inadequate flow of water to the source. If the dispenser is not at least a few inches above the end of the dispenser, air can enter.

Other problems include valves being blocked by debris, or improperly installed, such as the use of incorrectly sized pipe delivery or materials, the use of sharp or loose internals, or too long or too short to fall to the ground, or not used enough solid objects. For some installations PVC supply pipe will work but steel pipe is better.

Related FAQ’s

Can a ram pump run continuously?

Answer: As the water fills the distribution pipe, the higher it is pumped, the higher the pressure will be. As long as the water flows freely into the pump and flows out of the distribution pipe, the pump will continue to operate after start-up.

Can a ram pump uphill?

Answer: Over time, this water can eventually travel a long distance upward. One example is, our pump pushes about 1/2 liter of water per minute through 1 kilometer of hose, about 25 meters higher (vertical measurement) than where the pump is located

How far can a hydraulic ram pump push water?

Answer: With the proper size of hydraulic ram pumps, flow rates of 14 gallons per minute or 20,000 gallons per day are possible. Water can be raised up to 400 feet, depending on the amount and velocity of flow at the source.