What Is A Flat Belt Pulley?

Flat belt pulleys are used in transmission systems driven by flat belts, and can generally be used in high-speed, low-power textile, paperwork, and office equipment such as computer printers, flat pulley idlers have also been used for the rear of a traditional V-belt.

When the flat belt is off-centered on such a machine, and the belt rotates, the belt moves rapidly to the greatest distance above the crown and stays there.

Thin belts are designed for lightweight strength and efficiency. They are best suited for applications with small pulleys and large center diameters. Flat belts can connect pulleys internally and externally and can be available in infinite and joint construction.

Flat belts are also used for carriers. Compared to plied belts of the same horsepower, flat belts are 25% or more narrow, making a flat belt pulley smaller than a V-belt pulley Flat belts are also less expensive than those used with a snake belt in the pulley.

One safeguard is that the belt is able to slide in situations of over torque, preventing damage to equipment other than the belt itself. Thinner belts require thinner straps and thinner pulleys. Flat waistbands are not required. Flat belt driving pulleys apply a motive force to the belt.

Types Of Flat Belt Pulleys And Used

Following are the different types of pulleys for flat belts:

- Steel Pulleys

- Cast-iron Pulleys

- Fast and loose Pulleys

- Wooden Pulleys

- Paper Pulleys

1-Steel Pulleys

Steel pulleys are made of steel fabric and have great strength and durability. These pulleys are lighter (approximately 40% to 60% less) according to steel pulleys of the same capacity, and are drafting to run at higher speeds The coefficient of friction of a leather belt has not improved completely equivalent to that of a cast iron tube.

Typically, a two-sided steel bridge is constructed. The clamping action of the hub protects its shaft pulley; So no key is needed except in the most important service. Steel pulleys are usually equipped with adjustable frames that have different sizes of frames to accommodate their use.

2-Cast-iron Pulleys

The pulleys are usually made of cast iron. The rim is mounted on the grid from the center boss by arms or spokes. The arm is straight or convex, and the cross-section is usually rounded. Cast iron pipes are usually circular in shape.

If the mold slips in the mold, the handle is in a stronger position and more likely to break. The rounded arms loosen rather than break. There is a weapon near the hub. It is known as a slightly rounded crown. The crown centers the belt around the pulley as it moves. Mouth width can range from 9 mm to 300 mm.

Cast iron pulleys can be solid or split. When it is necessary to use a pulley that holds on old pulleys, etc., or the ends are swollen, it is convenient to use a split tube spaced between the faces and easily bolted, and fastening it firmly to a rod on two sides will be used. Submersible wrenches are used to move heavy objects

3-Fast And loose Pulleys

Quick and easy mounting switches allow the switch to be switched on or off. A high-speed pulley is mounted on the rod, while the soft pulley works independently.

The belt operates on a fast pulley to transmit power through the machine, when it does not need to transmit power through the machine it is sent to a slack pulley so the release of one machine does not interfere with other machines running on the same line shaft is it the way of the work.

A cast iron or gun metal pile is collared at one end to prevent the shaft from rotating in the light pulley. The diameter of the high-speed pulleys is larger than that of the smooth pulleys so the belt runs slower on a smooth pulley. Lighter pulleys generally have longer cabs to reduce wear and tear and need proper lubrication.

4-Wooden Pulleys

Wooden pulleys are lighter and make them more susceptible to scratches than wrought iron or steel pulleys. This machine has 2/3 of the same size cast iron. Typically, it is made from selected maple that is placed in slots and glued together under high pressure. They absorb water with a protective shell or varnish to prevent them from fighting.

These pulleys are rigid or divided by a screwed iron hub or have adjustable bumps that prevent frictional resistance from being set up between them and the shaft These pulleys are used for motor drives where contact pressure between the pulley face and the belt is prohibited.

5-Paper Pulleys

Paper pulleys are made from reinforced paper fibers and have metal centers. These pulleys are generally used to belt transmission from electric motors when the center-to-center shaft distance is limited.

Related FAQ’s

What are flat pulleys used for?

Answer: Flat belt pulleys are designed for all types of flat belts. It is commonly used in compressor drives, pumps, blowers, machine tools, textile machinery, paper, chemical and automotive industries, and many other industries.

What material is used for flat belts?

Answer: Flat belts are usually made of leather, rubber, and fabric. Leather belts have a high coefficient of friction (can transfer more force) and are therefore ideal for thinner belts. Several belt components are cemented together to give the desired belt thickness.

Why are flat belt pulleys crowned?

Answer: The purpose of a crown pull (or narrow tube) is to help check the belt. Under most operating conditions, the belt will follow the most complicated path. Therefore, it makes sense to have a larger diameter of the pulley at the center than at the edges.

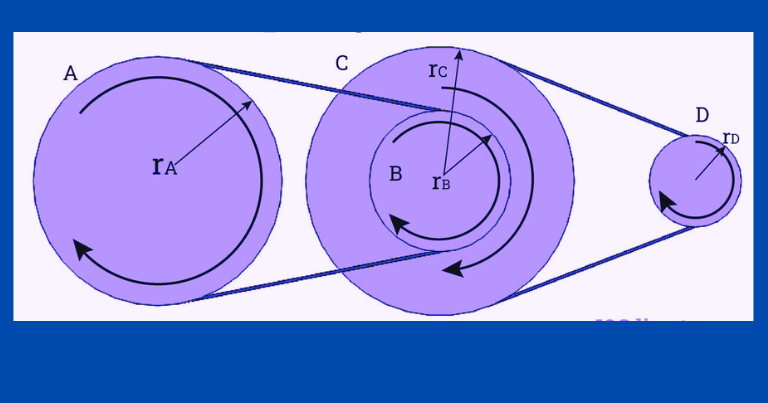

How do belt pulleys work?

Answer: Chains and gears, like belt pullers, transfer energy from one blade to another through belts and wires as the distance between the two wires increases.

What is the belt pulley problem?

Answer: A belt that is too loose on the pulley will cause it to slip, increasing the heat due to friction. This heat will damage your rubber boots and cause the boots to crack and break. A belt that is too tight can add stress to your bearings and cause your motor to over-amp, leading to motor failure.