What is a Conveyor System?

A conveyor device is a technique for shifting programs, products, components, parts, and gadgets for manufacturing, delivery, or relocation. The distinctive styles of conveying structures consist of pneumatic, screw, belt, and roller. The creation of man or woman structures relies upon on the substances to be moved, which incorporates their weight, dimensions, and capability to be transported.

Though conveying systems are important to material coping with and manufacturing, they’re also used for manufacturing packages, such as sintering, element and assembly finishing, and component washing. In the majority of instances, they may be computerized although unautomated designs the use of chutes and rollers are commonplace in retail, cloth handling, and transport programs.

Types Of Conveyor Systems

There are a mess of conveyor types, designs, and methods. The maximum not unusual types are belt, roller, and overhead with overhead and ground-mounted being the two broad categories. Conveying structures have as many advantages as there are types and are an everyday part of large-scale operations.

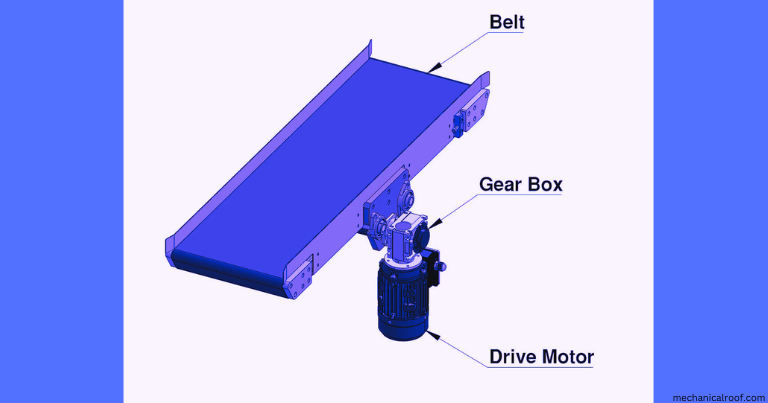

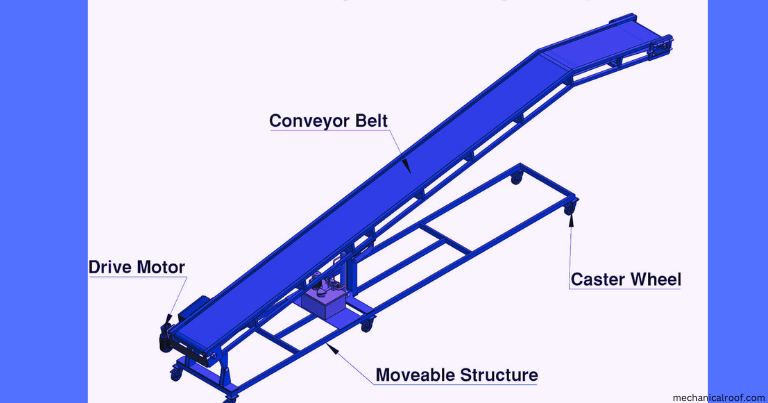

Belt Conveyors

Belt conveyors are the most common and simplest shape of conveyor and can have variable speeds. They have a transferring belt that rests on a steel frame that supports the belt and the substances being moved. Ones that have a supporting body beneath are known as sliding style. When the belt is supported through intently located rollers, it’s miles known as a roller belt style.

Gravity Roller Conveyors

Gravity roller conveyors have a set of equally spaced rollers connected to a facet frame. The function of the rollers presents floor-to-region substances for motion. If a gravity roller conveyor is tilted or installed on an angle, materials pass with the aid of gravity. Though portions of various sizes can be loaded on a gravity curler conveyor, workers need to be cautious of large substances walking into smaller ones. Gravity roller conveyors are used by shipping groups to load and unload trucks.

Motorized Roller Conveyors

Motorized roller conveyors use vehicles, positioned along the conveyor frame, to power calmly spaced rollers. The layout is just like a gravity conveyor with the addition of vehicles. The number of motors depends on the burden to be moved and the general layout of the system. The connection between the rollers can be a series or belt. In some structures, there may be a sensor that starts offevolved and forestalls the motor to avoid portions getting packed collectively.

Slat Conveyors

Slat conveyors have the same layout as chain conveyors with flat slats related to the chain. In a few methods, they may be similar to belt conveyors with slats changing the belt.

The slats have a completely easy surface that forestalls harm or harm to items being moved, making them ideal for meeting applications.

Overhead Conveyor Systems

There are numerous distinctive varieties of overhead conveyor structures, every of which has a similar function with a special design. The important purposes of overhead conveyors are to loose up ground space and make part and component movement easy and efficient.

Enclosed Track Conveyor An enclosed music conveyor has an enclosure that absolutely covers the trolley connectors with handiest a small gap for the motion of the trolley. The enclosure protects the music from wear and makes it less complicated to region bends and curves inside the device.

Open Track Conveyors – Open music conveyors do not cover the track and use I beam as the track. They are clean to install and ideal for long direct configurations.

Chain Overhead Conveyors Chain overhead conveyors use a continuously powered chain that runs alongside a song. Fitted to the chain, at everyday intervals, are pendants from which parts or products cling. In different designs where pendants are not used, pusher dogs may be used to transport trolleys along a 2d song located beneath the chain song. This form of system is referred to as electricity and unfastened.

Chain Conveyors

Chain conveyors may have or several sets of chains that make touch with the lowest of gadgets to be moved. The materials relax at the chains as they may be moved. Ones that have a heavy frame will have pallets placed immediately on them. Due to the sorts of objects chain conveyors flow, they function very slowly.

Monorail Conveyors

Monorail conveying systems have carriers to move materials and are best to be used over lengthy distances. Rails are suspended from the shape of the building and have power provided via signal traces from conductor traces within the hooked-up rails. Monorail conveyors make use of the distance above the manufacturing region. In a few designs, the companies lower to the level of production and then go up, out of the manner.

Power and Free Conveyors

Power and free conveying systems are designed to transport parts through the manufacturing and meeting procedure. Items being assembled flow from workstation to notebook. They forestall at every station to be worked on and then flow on. Power and free systems are a special shape of overhead conveying gadgets.

Unlike non-stop go-with-the-flow chain conveying systems, power and unfastened structures make it possible to prevent person masses from adjustments.

Inverted Conveyors

Inverted conveyors are floor-mounted and can be used as electricity and unfastened conveyors. They normally have a drive device that doesn’t contain a belt or chain.

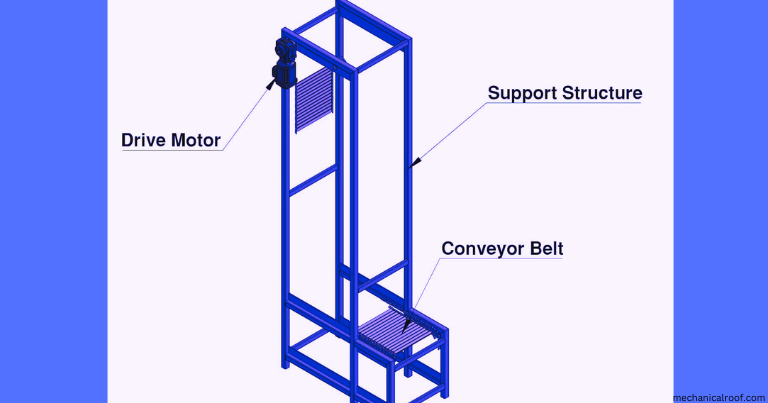

Paternoster Conveyors

Paternoster conveyors are a vertical conveying gadget that utilize identical spaced load companies related to a sequence pressure, which actions in a regular loop. They are also referred to as platform conveyors.

Chute Conveyors

Chute conveyors have a smooth flat surface manufactured from wood, steel, or plastic this is set on an angle in a frame, which may be immediately, spiral, or round. Items are slid down the surface.

Screw Conveyors

Screw conveyors are used to transport bulk substances consisting of granular merchandise, chips, and free substances. The important part of a screw conveyor is a rotating helicoid on a shaft inside a pipe. The blades of the screw flights are designed to hold the cloth upwards.

Pneumatic Conveyors

Pneumatic conveyors transport bulk substances using pressurized gasoline that pushes the material through a sealed pipeline. As the strain builds within the pipeline, powders or granular substances are lifted and moved through the pipe.

Vibratory Conveyors

A vibrating conveyor uses vibrations to transport substances alongside a conveying trough and is right for substances which includes grains, numerous solids, veggies being picked in an area, and quarried rocks. The agitations and constant movement gently move merchandise via vibration cycles. Each shape of the vibratory conveyor has a specific layout to match its characteristics with ones for mining being radically exclusive from those made for harvesting and meal manufacturing.

An essential benefit of vibrating conveyors is their awesome performance in the harshest conditions and environments.

Chain on Edge Conveyors (COE)

A chain-on facet conveyor is an unmarried strand chain conveyor that runs on its aspect and makes use of a roller chain that runs in a plate-supported channel. The severa sorts of twists & turns a COE made allow it to be more versatile than conventional chain-driven conveyors.

Skid Conveyor

Skid conveyors are some other form of floor-installed conveyor that move products on furnishings that have longitudinal runners known as skids with journeys being longitudinally and transversely. There are numerous elements to a skid conveying machine that consist of electricity rollers, pivot tables, travel carriages, and two-strand chain systems. Skid conveyor structures are valued for their performance and quiet mode of shipping. The versions in skid conveyor structures are because of the numerous components and manipulate systems that may be protected.

Friction Conveying System

A friction conveying system makes use of a motor to pressure a friction wheel made from nonmetal fabric to create driving pressure. The device includes a friction force, load bearing song, transfer, stopper, trolley, elevator, and steel structure. Friction-conveying structures is a safe opportunity to power and unfastened structures with the main advantage of a working purifier and quieter. They have a flexible format, unit production, clean velocity converting, can without problems be accelerated, and low general fee.

The most important purpose for friction conveying systems is to help with operations that have an excessive production price. They may be inverted or overhead relying on their fundamental design. Friction conveying structures transmit pressure without delay to a skid, slide, pallet, or provider the usage of a friction wheel.

How does A Conveyor System Work?

Conveyor structures paintings as an indispensable part of a bigger system. When explaining the function of a device, it’s far essential to observe all factors of the overall production method and the way the numerous pieces suit collectively. Much of the willpower of the workings of the device is set at some stage in the design section. Once the system is in region, its internal workings turn out to be a complicated shifting process that is essential to the efficiency and success of an operation.

Conveyor System Works

To restriction the discussion of conveying systems, the statistics below makes a speciality of belt conveying systems considering they are the most commonplace.

Belt

Belt conveyors use a device of motorized pulleys which have a belt made from thick long lasting cloth looped over the pulleys.

Support System

The aid system lets in the belt to transport easily. It is specifically designed to hold the shifting fabric without sagging. In the design segment, the burden ability of the frame is decided and the body is built to fulfill the desires of the operation.

Pulleys

Conveyor belt systems have at least two pulleys to manipulate belt motion, a pressure pulley and tail or return pulley. In among them are loafer or dummy pulleys which can be moved by using the belt. The force pulley pushes or pulls the weight, whilst the tail pulley returns the belt. As can be seen within the diagram, loafer pulleys serve quite a few functions in guiding the belt, which include controlling its anxiety.

Belt Cleaner

The motive of a belt purifier is to get rid of any carryback that can remain on the belt after the burden is discharged from the belt. Carryback is not unusual in all belt structures and is one of the fundamental troubles that causes belt malfunctions.

Drive

The force for the belt may be located in various positions inside the conveying device. For most belt conveyors, the drive is placed at the release or head of the belt. Other locations can be anywhere alongside the belt depending on the layout. AC vehicles are normally used to electricity the pulley that actions the belt.

Applications Of Conveyor System

As automation and manufacturing have emerge as extra technologically advanced, conveyors have rapidly evolved into an vital a part of cloth processing and motion as well as improving the rate of various production operations.

Conveyor System Applications

Sintering

Sintering is a production system used to significantly lower the temperature of a piece just beneath its melting point to form and shape the piece.

Packaging

A packaging conveyor is designed to help with product packaging, along with placing finished merchandise in containers, efficient labeling, or practise of products for delivery. The characteristic of a packaging conveyor gadget is to move products from finishing touch and assembly for shipment. They offer a safe technique of shifting materials and avoid the need for employees to carry heavy items.

Production Line

A manufacturing line conveyor is designed to bring paintings to employees, which avoids the need to move an assembly group. The blessings of a production line conveyor is to without difficulty move products thru the meeting system for each task to be correctly accomplished. What begins as uncooked substances at the start of the assembly method is a completed product at the quit.

Pharmaceutical

The pharmaceutical industry requires specifically designed conveying systems that can be established in a sterile environment but be bendy, dependable, and easily reachable to prevent infection. Pharmaceutical conveyors flow products inside and out of sterilization tactics that use toxic chemicals. This requires conveyors made from materials able to withstanding such exposure.

Metalworking

The demands for metallic production has improved the use of conveying structures to enhance productivity and performance. The numerous processes of metalworking can be finished correctly and exactly by means of the use of a conveying machine. Cutting and molding for the manufacturing of huge portions of merchandise may be completed faster. Press out conveyors are used to cast off molded portions from the urgent line or on to other operations.

Airport

Though airports have human beings transferring conveyors, the principle conveying machine is for bags dealing with, which accelerates the method of having bags from the checkin counter to the plane and off the aircraft to bags pickup. Highly sophisticated and complex structures restriction guide involvement and pass applications and baggage. Airport conveying structures rent several different styles of conveying structures, which can be on an attitude, vertical, or horizontal.

Mining

Conveyors are critical for mining operations to move uncooked substances however ought to be long lasting enough to face up to extremely harsh conditions. Most mining operations are in secluded regions that make it difficult for vans to get entry to. Mining conveyors do away with the need to create a method for vehicles to reach the operation. Though mining conveyors range in length and period, the bulk of them are on an incline and flow several heaps of cloth. They should be frivolously loaded to avoid spillage or empty spaces. Depending at the design, they perform very unexpectedly as much as a hundred fpm.

Automotive

The automotive industry uses numerous sorts of conveyors for cloth coping with. Parts and vehicle bodies can be without problems moved from one operation to the following. They are especially beneficial in transferring heavy objects such as doorways, bumpers, chassis, and frames.

Food Processing

Food conveyors flow meals and organic materials correctly and quickly at a lower fee than that of guide labor. The time period meals conveyor covers a variety of systems that includes rollers, belts and dumpers or anything used to transport food merchandise thru the producing technique. As with all conveying systems, meals processing conveyors are customized to match the needs of the producer and the utility. The one aspect that makes them precise is the requirement to satisfy governmental policies for sanitation and cleanliness.

Printing

Printing conveyors, for display screen printing, use a conveyor dryer system for drying screen revealed material. Though there are different techniques for drying display prints, conveyor dryers are used for big extent manufacturing and come in several varieties.

Conclusion

• Conveying structures are an vital a part of automation and manufacturing.

• Each conveying device is developed to match a particular utility.

• Though belt conveying systems are the most and easily recognizable, other sorts include screw, pneumatic, chute, and roller.

• As with any shape of gadget, conveying structures require regular upkeep.

• Safety is critical with conveying structures. OSHA and ASME provide suggestions and policies concerning the use and construction of conveying structures.