Introduction

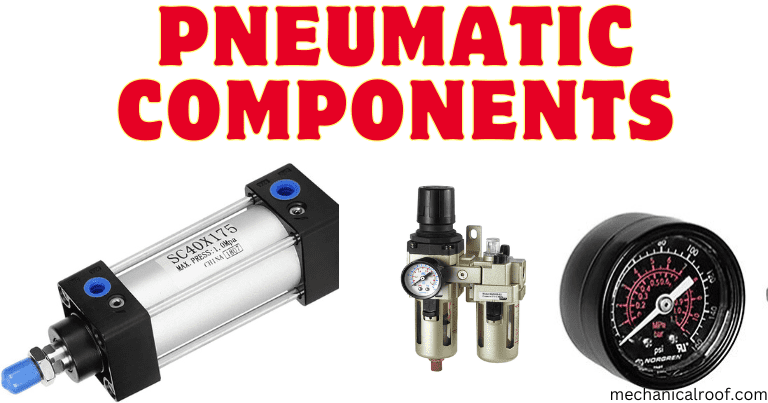

This blog will take an in-depth look at Pneumatic Components. The blog will bring more detail on topics such as:

- What are Pneumatic Components?

- Where is Pneumatics Used?

- Components of a Pneumatic System

- Working Principle of Pneumatic System

- Pneumatic System Components and Their Function

- Related FAQ’S

- And Much More…..

Pneumatic systems represent the most widely used technology today, with applications ranging from the automated systems of various industries to personal equipment In this overview, we look at the various components of pneumatic systems, how it works, and how it is commonly used in detail.

What are Pneumatic Components?

Pneumatic components refer to the interchangeable components that make up a pneumatic system or device. In other words, they are designed to take air from the atmosphere clean it and compress it, then send it through an opening control to an active mechanism for triggering.

Before we look at what these parts of the pneumatic system are and what they do, here is a brief introduction to how pneumatic-based systems work. This will give you an idea of what is involved at each stage of the process and help you better understand the role of each stage.

Where is Pneumatics Used?

Pneumatic systems are used in a wide variety of applications because of their versatility and ease of use. They are generally the basis of industrial equipment and various industries such as manufacturing, oil, gas, and electricity automation.

For example, a variety of pneumatic components are used to operate the robotic arms of manufacturing tools to move, sort, assemble, or hold materials They also find value in safety systems as it is located within these areas and can even be used to operate electrical systems remotely.

Pneumatic products and systems are popular for many reasons. It makes it easier and cheaper to fly because the air is not free and accessible. Air-powered machines also operate without the risk of fire and explosion. That’s clean, in addition to being suitable for use in the food, beverage, pharmaceutical, power, and electrical industries.

Components of a Pneumatic System

The function of the parts is important in the above air system. These are called pneumatic systems appliances or devices. The segments include the following—Note that this list of gases represents the major segments.

- compressor and air reservoir

- Functional air conditioning system (FRL) consisting of filter, regulator, and (mostly), lubricant

- Fittings for connecting valves and other parts

- Tubes for flying

- Valves for directing air to the driver in a controlled manner

- actuator which is usually a piston-cylinder mechanism.

Working Principle of Pneumatic System

Pneumatic systems operate on the principle that compressed air applies and transports energy. When air is exposed to space under high pressure, it stores energy. With clever devices, this power can be controlled and channeled into useful work. Here is the main trend:

- The compressor extracts air from the atmosphere and stores it in a reservoir or air storage tank.

- From here, the gas is pumped through a tube into what is known as a gas separation and cleaning unit.

- This unit consists of these parts: separator, filter, regulator, and lubricant.

- A separator uses centrifugal force to remove water from the air, while a filter removes anything like particles.

- The regulator adjusts the air pressure. But the grease adds some lubricant before the air moves to the next step.

- Clean, dry compressed air now enters the inlet.

- From here it enters ports on its way to the actuator where it will be used for motion.

- A piston is usually mounted in the cylinder to create motion of the compressed air. The actuator may also be a vane mechanism or a diaphragm.

Pneumatic System Components and Function

Now that you apprehend the programs of pneumatics, permit’s take a look at elements that such systems are composed of. These range from the compressor that to begin with draws air from the ecosystem, to the actuator that converts the transmitted force into motion. Here is a list of the main pneumatic components and their functions.

- 1. Pneumatic Compressors

- 2. Air Separator Units

- 3. Pneumatic Filters

- 4. Pneumatic Regulators

- 5. Pneumatic Lubricators

- 6. Pneumatic valves

- 7. Pneumatic Cylinders

- 8. Pneumatic Actuators

- 9. Pneumatic Fittings

1. Pneumatic Compressors

Pneumatic compressors take air from the encompassing space and compress it right into a smaller tempo. The compressed air then incorporates saved strength. This power is utilized by the pneumatic gadget to do beneficial work. Most regularly, the compressor shops the compressed air in a garage tank or reservoir.

2. Air Separator Units

These are components of pneumatic systems that assist in separating water (moisture) from the already compressed air. They are vanes that rotate rapidly around the wind. The centrifugal pressure exerted by the windings reduces the gas, which can then be removed without problems.

3. Pneumatic Filters

The air getting into the device from the compressor may additionally comprise impurities. These could grow to be clogging the gadget over time. To attain that, the filter out uses a two-stage machine including vanes and a filtration element. The vanes spin the air around, whilst the element acts as the sieve to remove particles.

4. Pneumatic Regulators

Just as their call suggests, these pneumatic additives regulate the drift of air as it goes into the device. The basically pneumatic regulator is a spring-loaded unit that, utilizing a variable valve, increases or decreases the airflow as needed.

A growth way extra strength is transmitted to the actuator, at the same time as decreased airflow approaches the other. A stress gauge is likewise frequently added to the regulator. This lets the device’s operator ensure the proper control of its operation.

5. Pneumatic Lubricators

Sometimes, and depending on the type of device or machinery, a lubricator is one of the components of pneumatic systems. This is generally visible in air automobiles and strength gear that use pneumatics to paint.

The section sprays lubricant into the compressed air coming out of the separator unit, helping to lubricate the moving parts of the system to reduce friction

6. Pneumatic valves

The air sections have valves that properly direct the air and perform essential functions. These serve to control the flow and pressure of air in the ventilation system and have a collection of mechanisms for opening or closing as required Air valves can be of various types e.g.

- manually operated valve

- The leg support

- Manual operated valve

- push button machine

- Solenoid actuator

Air valves are often used as solenoids. The solenoid is a plunger that controls air flow to perform the desired function.

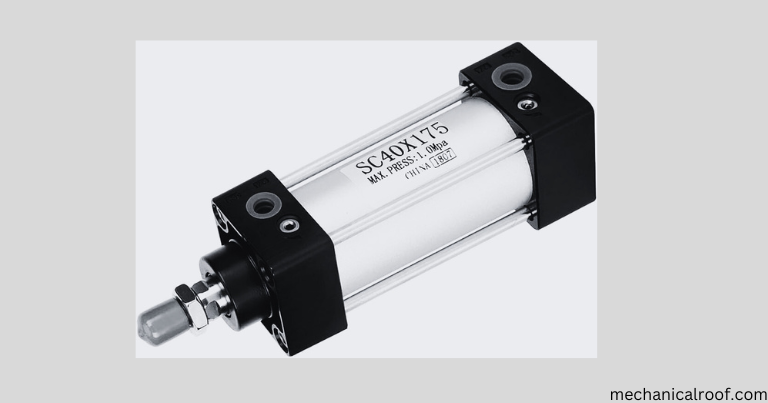

7. Pneumatic Cylinders

These parts of the pneumatic system have a piston which goes to convert the pneumatic energy into energy. The cylinders are fed by tubes carrying compressed or fresh air. A piston in the cylinder moves back and forth to create a cannula.

The pneumatic cylinder can be single-acting or double-acting. Single-acting cylinders use compressed air to push the piston in only one direction, usually with the addition of a return spring to pull it. The two cylinders allow the piston to be pushed back and forth.

8. Pneumatic Actuators

Pneumatic actuators are the parts that are going to do useful work under compressed air operation. This can be a linear motion to move or fasten a load, or it can be a rotary motion to operate a valve or other action and action.

Most actuators are cylinder based. These have a piston that can move into the cylinder. The cylinder receives compressed air from the guide valve. The force of the air then moves the piston and affects the required system or device.

9. Pneumatic Fittings

Fittings serve to connect pneumatic system components together, valves can be separate. They help prevent air leaks, making them important parts of pneumatic circuits. In addition to fittings, other important features include ducts that help move compressed air from one side of the system to another.

Related FAQ’S

What are pneumatic components used for?

Answer: Pneumatic systems capture air, reduce its volume, as it passes through the circuit, and force it to provide power for various industrial systems and everyday applications, especially small appliances often used, such as gas samplers and ventilators.

What is commonly used in pneumatics?

Answer: Compressed air is used in ventilation systems in stationary plants such as factories because compressed air can be supplied efficiently. Usually water is removed from the air and a small amount of oil is added to the compressor to prevent corrosion and to lubricate the mechanical components

Why is a pneumatic system used in industry?

Answer: Pneumatic systems offer many advantages in industrial situations as they are suitable for applications requiring high power, high speed, and accuracy. Wind systems are also relatively inexpensive because they rely on open atmospheric air and expensive supplies.

Which fluid is most commonly used in pneumatics?

Answer: Compressed air is typically used for ventilation systems, but inert gases such as nitrogen can also be used depending on application requirements. A typical air system uses a compressor to pump air into the receiver which is capable of holding large quantities of air which is then used by the system when needed

What controls a pneumatic system?

Answer: The air handler uses compressed air piped through plastic and copper pipes—from the controller to the manifold. In this way, the control system works with the help of sensors and thermostats that can bleed or hold the line pressure from the sensor to the actuator.

What is pneumatic stress?

Answer: Pneumatic stress is a strain that is exerted via a pressurized fuel. There are many varieties of gases that can be used to create pneumatic strain. One of the most normally used ones is compressed air.

What is the pneumatic problem?

Answer: The most basic troubles are probable to be a gradual-shifting, drifting actuator, inadequate stress, & issues with valves or the filtration unit. You can study extra about pneumatic systems and some of the maximum commonplace issues here.

Conclusion

In a pneumatic system, various parts of the pneumatic system perform various functions, enabling the transfer of hydraulic energy to various mechanical processes and other power tools and equipment Depending on the required task, these may be form tools active controls, power tools, and so on.