Introduction

Hydraulic fittings can be found in almost all industries, but not all hydraulic hose fittings can do the same job. Given the extent of their usage, it is important to choose the right types of hydraulic fitting to suit your application, hose size, and assembly.

Whether you are a professional in the industry or just learning the ropes, you are required to be able to identify the right hydraulic fitting for the job. We are here to make it easy for our readers with a complete guide to the kinds of hydraulic hose fittings, their applications, and how to use them. Keep continuing to learn everything you need to know.

What Is A Hydraulic Fitting?

Fittings are mechanical elements that enable two or more pipe or hose elements to be joined safely and efficiently. There are several kinds of fittings utilized in different applications and environments, each with its characteristics & benefits.

Hydraulic fittings are a special kind of fitting utilized in hydraulic systems to join pipes and hoses that carry fluids normally under high pressure. These hydraulic systems are in a wide category of applications, from heavy machinery, process industry, and construction vehicles to industrial production equipment and lifting & handling systems.

Hydraulic fittings are designed to withstand high pressures and temperatures. They offer a tight, secure connection in demanding working environments.

Hydraulic fittings are parts utilized to connect hydraulic hoses to other components. Hydraulic couplings are utilized in a category of machines and equipment across all main industries. They are basically used in manufacturing hydraulics and assembly lines, water & sewage systems, oil refineries, and construction site hydraulics.

Hydraulic fittings each one serves a different purpose. They are also manufactured in different sizes, materials, types of seals, and temperature and pressure tolerances. For instance, a hydraulic fitting can either enable or prevent the flow of fluid. In some cases, fittings are dual-utilized and can do both. But the main important quality of a hydraulic fitting is how effective it is in creating a tight seal.

The two main types of hydraulic connections are crimped fittings and field-connected fittings. As the name implies, field attachable connectors or reusable fittings consist of a socket and a nipple and can be installed anywhere without the need for a crimping tool.

A crimped connector is a permanent solution that is sealed with a crimping machine. Crimped connectors have a much higher level of security than a field attachable fitting but do require the equipment to make the seal. While different types of crimping machines are bigger units typically stationed in a workshop, there are also numerous portable and handheld hydraulic crimpers available to provide flexibility in the gap between crimp couplings and field attachable fittings.

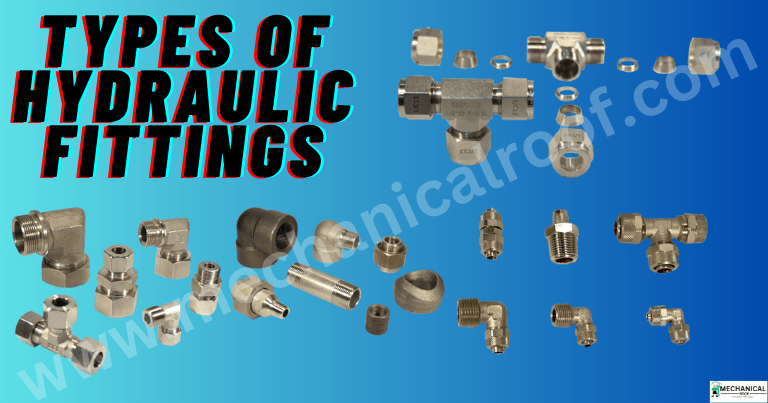

They can be made from a variety of materials, like stainless steel, brass, aluminum, or plastic. In extra, they can be available in a category of shapes and sizes to suit the requirements of each application (straight, elbow, tee, cross, etc) Let’s get blow to what is interesting, as I hope it is already clear to you what a fitting is.

Types Of Hydraulic Fittings

They are divided into two main categories: high-pressure fittings & low-pressure fittings. High-pressure fittings are utilized in systems that convey fluids at high pressure, like hydraulic systems of heavy machinery or drilling equipment.

Low-pressure fittings are utilized in systems that convey fluids at low pressure, like lubrication systems. They are jointed to pipes and hoses by different methods, like threading, compression, or mechanical bonding.

They can also have different designs, like straight fittings, elbows, tees, or cross fittings. These enable pipes and hoses to be connected at different angles and configurations. It is important to choose the right kinds of hydraulic fitting for each application to ensure a secure and durable connection.

In addition, hydraulic fittings are installed and maintained correctly to prevent leaks and damage to the system. Let’s look at the different kinds in more detail.

1-Double ring fittings

A double-ring compression fitting, also called a compression union fitting, double olive fitting, double ferrule, or “Swagelok” fitting, is a kind of fitting utilized in piping and hose systems to generate a secure, leak-tight connection. These kinds of fitting is commonly utilized in medium and high-pressure fluid handling applications.

Connect them to the pipe and secure them using a wrench or open-end wrench to achieve a watertight connection.

One of the benefits of double-ring fittings is their straightforward installation process and do not require soldering glue, or special tools.

Another benefit of double-ring fittings is that they are very versatile and can be utilized with different sizes of pipes and hoses, like copper, stainless steel, and plastic tubing. Make sure that the double ring fitting is compatible with the kind of tubing utilized and that it is seamless.

And, stay tuned, due to I have all the sizes and fittings you require. Elbows, reducers, crosses, tees, valves, sleeves, and many more. Manufacture them in 316/L stainless steel. They can also be fabricated in 904, Alloy 20, Duplex, Super duplex, Incoloy, Hastelloy, Inconel, Monel

2-ASME hydraulic fittings

ASME B16.11 3000, 6000 & 9000 PSI fittings are a kind of high-pressure fitting utilized in industrial applications where secure, high-pressure resistant joints are required. These fittings are drafted and fabricated according to American Society of Mechanical Engineers (ASME) B16.11 specifications. They are available in different sizes and shapes to suit the needs of each application.

The number utilized to describe these fittings (3000, 6000, and 9000 PSI) indicates the ASME pressure rating they can withstand. ASME B16.11 3000 PSI fittings are perfect for high-pressure applications that need a maximum strength of up to 3000 pounds per square inch. ASME B16.11 6000 PSI fittings are special for even more demanding applications that need a maximum strength of up to 6000 pounds per square inch. Finally, ASME B16.11 9000 PSI fittings are the most powerful. They are utilized in applications requiring a maximum strength of up to 9000 pounds per square inch.This standard covers NPT & and Socket Weld jointed, although we also have them in BSPP.

3-Single-ring hydraulic fittings

Redfluid’s single-ring fittings are drafted for connecting pipes and tubing in hydraulic systems and comply with the Deutsches Institut for Normung DIN 2353 / ISO 8434-1 standard. These fittings are available in different sizes and shapes, from 4 to 42 mm OD, to suit different tubing and pipe diameters. Depending on the series and pipe diameter, these fittings can endure pressures of up to 800 bar.

The range of single-ring fittings includes a wide category of shapes, like straight, cross, tees, elbows, mixed male or female x-ring thread, wall bushings, or weld fittings, among others. These fittings are offered in two standard materials: 316 stainless steel and carbon steel.

In summary, Redfluid’s single-ring fittings are a suitable solution for connecting pipes and tubing in hydraulic systems and are offered in different sizes and shapes to suit the requirements of each application. In addition, their ability to withstand high pressures makes them ideal for applications that require extra strength.

4-Hydraulic quick and automatic fittings

Two types of automatic and quick fittings are available: Push-in fittings & push-on fittings.

A-Push-On Fittings:

They consist of an outer metal nut and a compact inner nipple. these components involve inserting the tube nipple and tightening with the outer nut.

B-Push-In Fittings:

The tube is inserted into the push-in fitting and an outer ring, which is basically red or blue plastic, holds the tube without the need to tighten any nuts. They are also named “Festo” type.

Both kinds of fittings are available in brass and stainless steel and can be found in a wide category of shapes and forms, and different threads, including BSP, BSPT, NPT, and metric. These are also comes in different dimensions, from 4 mm to 16 mm outside diameter (OD).

5-High-pressure hydraulic fittings

There is a wide range of products that are acceptable for working pressures above 400 bar, up to 4140 bar. For high pressures, special joints known as “cone and thread” Medium-Pressure or “cone & thread” High-Pressure are used. Medium-Pressure products normally work up to 1380 bar, while High-Pressure products can work up to 4140 bar.

The inventory comprises needle valves, ball valves, and check valves., as well as fittings in different shapes, like elbows, tees, sleeves, and plugs. In addition, the fittings come in Male x Male, Male x Female, or Female x Female variety. It is one of the typical fittings for hydro generators and high-pressure hydrogen pipelines. The joint is watertight and high pressure. These fittings can only be joined to pipes with specially coned ends compatible with the rest of the fittings.

What Are Hydraulic Hose Fittings?

Hydraulic fittings can be made from numerous accoutrements , the most common bones being plastic, pristine sword, or brass. The type of assembly or assiduity operation generally determines what material is suitable.

Let’s take a near look at the most common accoutrements used in hydraulic fittings

1-Plastic Hydraulic Fittings

These types are much more resistant to erosion compared to their essence counterparts. still, they’re physically weaker and lower durable. This is why they aren’t preferred for hydraulic operations despite the low cost. Essence fittings are more suited for high-pressure conditions set up in artificial operations.

2-Steel Hydraulic Fittings

These types of fittings are made of sword blends which means they’re far more durable than their plastic counterparts. For case, carbon sword fittings can repel temperatures from-53 °C up to 260 °C.

3-Stainless Steel Fittings

As the name suggests, these are the pristine sword variant of sword hydraulic fittings. Stainless sword fittings are utilised in situations where they would need to repel temperatures ranging from-253 °C up to 648 °C. Their

tough nature makes them the choice of fitting for largely sharp surroundings. Fittings made from this material are generally rated up to 10,000 psi, with some special designs able to oppose up to 20,000 psi. The primary debit for these is their high price, which generally prompts diligence to consider druthers for lower hard-wearing operations.

4-Brass Fittings

These aren’t as strong or durable as their pristine sword counterparts. still, they can give a tight seal that prevents leaks and meet SAE( Society of Automotive Engineers), ISO( International Organization for Standardization), noise( Deutsches Institute für Normung), and JIS( Japanese Industrial Standards) norms, among others. Brass fittings are rated for temperatures from-53 °C up to 204 °C, and pressures up to 3,000 psi.

5-Aluminium Fittings

Hydraulic fittings made from aluminum are less common but do live and are used in certain operations. They’re lighter than swords but are resistant to erosion. These rates make them preferable in transportation hydraulics similar to the automotive assiduity.

Permanent VS Field Reusable Fittings

Permanent hydraulic fittings( also known as waved fittings) bear a releasing machine to be attached to a sock, while applicable hydraulic fittings connect to hoses using a wrench and a vice.

Permanent hydraulic fittings are much more common than their applicable counterparts. They’re easy to identify and assemble with the use of a hydraulic crimper and have a character for being the most dependable type of befitting. They’re wide in the fluid power assiduity due to their ease of use. On the other hand, applicable hydraulic fittings aren’t as popular because of their advanced cost and time- consuming process.

With the growing fashionability of movable hydraulic crimpers suitable for mobile technicians and on- point use, applicable hydraulic fittings are gradationally falling out of favor.

Fitting Ends And Connector Types

The three most common befitting ends and connector types for hydraulic fittings are the O- ring, the slept angle, and the phased thread connectors. Although these are the most popular choices, several other types are used in different and specialised operations.

Since hydraulic fittings vary in how they seal connections, it’s important to consider seeking professional or specialized advice to avoid leaks or other dangerous scripts.

The primary fittings and connector types are

1-O-Ring Face Seal (ORFS)

Hydraulic fittings equipped with this kind of sealing system give a secure and dependable elastomeric seal preferred for operations with any threat of oohing fluids. They can exclude leaks in hydraulic systems that operate at pressures that can reach up to 6,000 psi. ORFS fittings can be resolved into the following types

- Straight ORFS Fitting– A straight screw connection with a manly ORFS connection point to manly PRT, G, or metric vestments.

- Elbow ORFS Fitting– Is an elbow screw connection with an ORFS womanish connection and an ORFS manly connection at an angle.

- Tee ORFS Fitting– This is a T- shaped connection with three connection anchorages. One is a womanish ORFS connection harborage, with two other manly ORFS connection anchorages.

- Cross ORFS Fitting– This is equipped with four manly ORFS connection anchorages and is useful for distribution or combining.

2-DIN Or BSP

These stand for ‘ Deutsches Institut für Normung ’ and ‘ British Standard Pipe ’ and are a type of hydraulic befitting generally used across Europe.

3-DIN hydraulic fittings

Are exchangeable with different brands of fittings. They’re used in artificial, construction, and oil painting operations and diligence.

4-BSP hydraulic fittings

These fittings are used primarily for hitching pipes and sealing, which is achieved by interlocking the external( manly) with the internal( womanish) thread. These fittings are generally set up in plumbing diligence and are extensively accepted worldwide except for North America due to the American National Pipe Tapered Thread( NPT) standard.

5-Mated Angle

Hydraulic fittings with an angle seat equipped with either straight or resemblant vestments for sealing. When the manly and womanish counterparts are threaded together, the vestments don’t form the seal. rather, the befitting mechanically creates a seal by bringing the lovemaking angle seats together, making the seal.

6-Tapered Threads

This type of hydraulic fitting has a manly and womanish thread. manly fittings have their vestments on the outside, while womanish fittings have theirs on the inside. The phased thread deforms when the manly and womanish fittings are threaded together.

This accordingly applies pressure on the couplings, which produce the seal. Unfortunately, these fittings are prone to shredding and polluting sensitive areas, which frequently causes them to be banned for use in hydraulic and curvaceous systems. In addition, the lubricity of these fittings has also been known to be over-torquing.

What Does JIC Mean In Hydraulic Fittings?

JIC stands for Joint Industry Council, defined by SAE J514 contraction fittings that have a 37-degree flare seating face and resemblant vestments. These fittings are generally manufactured using nickel blends, brass, carbon, and pristine swords.

JIC hydraulic fittings and connections are generally used in fluid power systems. Both the manly and womanish fittings have 37-degree seats, whose seals are made by creating a contact between the flare of the manly element and the coned seat of the womanish element. Connections of this type are considered mechanical.

Advantages of JIC Hydraulic Fittings include:

- Have a wide range of fittings to feed to all diligence

- Are created with SAE regulations and fittings in mind, making them largely compatible and protean

- Work impeccably in high- temperature operations

- Are largely durable. They can be disconnected and reconnected constantly without damaging the fitting.

Disadvantages of JIC Hydraulic Fittings include:

- These fittings have a lower pressure standing compared to other types. This makes them infelicitous for operations with high climate

- Their operation is limited only to hydraulic fluid and non-critical operations due to the essence-to-essence design.

- They’re veritably susceptible to cracking performing from over-tightening.

How To Identify Hydraulic Hose Fittings

To right identify the hydraulic sock fitting for the operation determine the type of fitting match the harborage connection with that of the sock and determine the type of seal and befitting design and size of the thread.

1-Determine the type of fitting

Check to see if the fitting is waved or applicable. Newer outfits and connections are generally waved.

2-Match the port connection with that of the hose

Another important part is to make sure that the harborage connection matches the one on the hydraulic sock. relate to the table below.

| Port Connection | Hose Connection |

|---|---|

| BSPP (JISPF) | 60 degree NPSM Swivel |

| BSPT (JIS-PT) | 30 degree Flare (Metric) |

| DIN Metric | 30 degree Flare (Metric) |

| ISO 6149 | O-Ring Face Seal (ORFS) |

| JIS-B2351 | 24 Degree Flareless (DIN) |

| Metric Taper | 45 Degree Flare |

| NPT-NPTF | 37 Degree Flare |

| SAE Straight Thread | 24 Degree Flareless (SAE) |

3-Determine the type of seal

Pertaining to the physical confines and specialized characteristics, identify whether it’s using an O- Ring, a Mated Angle, or a Phased Thread. slept Angles are grounded on straight and resemblant thread types, in which the manly and womanish units will form the seal. Phased vestments will have the vestments on the outside if it’s a manly unit and on the inside if it’s womanish. Incipiently, O- Rings( ORFS) will formerly include the seal.

4-Determine the fitting design and size of the thread

Relate to the list below for the most common and extensively used hydraulic fittings.

- NPT/NPTF- This is the most generally used type of thread in North America and is recognisable by its phased inner periphery and external periphery. This creates a tone- sealing fitting.

- BSPT (JIS-PT)- Also known as the British Thread type is standard fittings espoused internationally for making connections and sealing pipe ends.

- Metric Taper- This is the most generally used thread type in Europe and is known for its precise spherical inner and external compasses.

- SAE Straight Thread- A thread type known for its trustability and reusability- has excellent sealing due to its 90- durometer O- rings.

- ISO 6149- This is equipped with a straight thread O-ring harborage useful for individuals harborage operations.

- JIS-B2351- This thread type is primarily used as a sock appendage for outfits manufactured in Japan or Korea. These generally come with BSP threads.

- DIN Metric- Since this thread type uses the German Industrial Standard, they’re popular throughout Germany and the maturity of Europe.

- BSPP (JIS-PF)- These are BSPP connectors that follow the standard British thread confines.

- 4-Bolt Flange- These come in a variety of types, feeding to either standard or heavy- duty operations.

How Choose the End Fittings For a Hydraulic Hose?

The criteria for choosing the right end fittings for hydraulic hoses are size, material, temperature, pressure, operation, and assembly. The proper assessment of these criteria is critical to ensure the safety and trustability of the connections. Each of the factors mentioned over is detailed below

1-Size– When it comes to the size, the important measures to consider are the internal and external compasses of the hydraulic fittings. The compasses have to be compatible with that of the hydraulic sock. Fittings over or under- sized won’t be sealed duly and beget the connection to fail or blunder.

2-Material– Different accoutrements have different parcels, which affect and determine the comity with the fluid. As similar, making sure that the fitting is compatible with both the hydraulic fluid and the working terrain is critical. Determine both and choose between brass, aluminium, sword, or pristine sword. The most extensively- used sealing accoutrements are O- rings made from NBR( Nitrile).

3-Temperature- Away from icing that the different accouterments that make up hydraulic fittings are resistant to the operating temperatures, the type of fittings should also be considered.

4-Pressure- The quantum of pressure the hydraulic fitting is subordinated to differ across varying diligence and operations. Make sure that the fittings are rated for the pressure range needed. Operating beyond the rated pressure may beget leaks and indeed peril to people in the working terrain.

5-Assembly– Hydraulic systems that bear frequent connections and dispositions of the sock or tube should consider hot- connect fittings. For case, hydraulic contraction fittings can also remove the need to weld or solder the fitting. It uses a contraction nut that tightens against the ferrule, creating a tight seal.

6-Application- Depending on the assiduity or operation, the fittings could be used for either mixing or distributing. As similar, hydraulic fittings similar as the T- shape and the cross-shape come into consideration.

7-Permanence– Demanding an endless fitting or bone that can be removed and changed constantly will affect the befitting style you choose. However, a field attachable fitting will work just OK, but if you need commodity endless and strong, If this fitting is going to be changed frequently.

Not all fittings are compatible with all hydraulic fluids. The primary hydraulic fluid types are petroleum- predicated, water- grounded or synthetic- grounded fluids.

How To Install Hydraulic Hose Fittings

Proper hydraulic sock fittings bear opting the right fitting, knowing the insertion depth, and using a hydraulic crimper.

A- Identify the correct hydraulic sock fitting by considering the size, temperature, pressure, style, material, and exposure. The type of hydraulic fluid used in operation should also be reckoned.

B- Ensure that you have the right type and size of length for the hydraulic sock needed for the operation. You can conclude to use sock knives to cut it to the correct length with clean ends. This will reduce the threat of assembly failures or impurities.

C- Determine the fitting’s depth of insertion, and place a mark on the hydraulic hose. However, apply lubricant and fit the sock into the fitting using the mark as a companion, If necessary.

D- Using a crimper, acclimate to the fitting’s periphery – relate to the applicable crimp map for specific instructions. The end of the sock should be placed within the releasing machine for releasing.

E- After vindicating that the crimper is set to the suitable periphery, clean the sock assembly. This will help any impurity.

How Connect Two Hydraulic Hoses Together

Before connecting hydraulic hoses, make sure you wear defensive apparel and allow pressure out of the hydraulic system first. You could be connecting hydraulic hoses due to damage on the former one, or you could just be connecting hoses of a new hydraulics system. However, follow the step-by-step companion below, If so.

Step 1 – Make sure that both hydraulic hoses are identical and have the right fittings.However, pipes, or factors, If the element is placed so that there will be disunion with other machines.

Step 2 – Clean all hydraulic hoses – their connectors and fittings. Once you have removed all signs of dirt and debris, install one side of the sock into the befitting and do to rotate it clockwise to strain.

Step 3 – Install the other hydraulic sock into the connector and hold it in place using a wrench. Rotate the connector until it’s tight enough that it locks in place.

Step 4 – Place any needed coverings on the sock and test the hydraulic systems under low pressure. Once no leaks have been set up, you may do to raise the pressure or temperature to normal operating situations.

How To Seal Hydraulic Fittings

Hydraulic fittings are sealed either through O- rings, thread sealants, or tone- sealing like SAE flanged fittings. They don’t need to be manually sealed.

Use Teflon Tape On Hydraulic Fittings

Teflon videotapes shouldn’t be used on hydraulic fittings since a seal is formerly created through an O-ring, essence face seal, or vestments. Although leaks can be caused by normal wear and tear and gash due to operations and changes in temperatures and pressure, leaks are generally a sign of incorrect use or connection of hydraulic fittings.

Should your hydraulic connections show any form of leak or damage, try to suspend the inflow of any liquid or material through the sock for examination and incontinently arrange hydraulics examination and repairs.

The flashback is that choosing the right hydraulic fitting for the functional terrain is critical to a safe work terrain.

Related FAQs

What is a Double Ring Fitting?

Answer: Understanding what a double-ring contraction fitting is helps understand why it’s a favorite among most people. Simply put, a double-ring contraction fitting is a type of contraction fitting also known as a Swagelok type, after the name of the company that developed this type of befitting, which is generally used in systems that bear a perfect seal for high-pressure fluids, but with the inflexibility to assemble and disassemble the connection snappily and regularly that only this type of befitting offers.

What is a DIN 2353 single-ring compression fitting?

Answer: Since you know the double ring contraction fitting, you can fluently imagine what the noise 2353 single ring contraction fitting is. This fitting is designed according to DIN 2353 and noise EN ISO 8434- 1 with W-shaped noise 3861( 24 ° cone) and as its name suggests it has only one contraction ring to induce the sealing of the connection.

The noise 2353 fitting was developed as a volition to traditional connections that bear a lot of time, trouble, and indeed special tools for installation, making them a real headache for systems that bear regular assembly and disassembly as described above. In addition, traditional connections generally don’t offer a veritably good seal, so it’s veritably common to induce leaks, especially when working with fluids similar to brume or hydrogen at high pressures where the only volition was to weld.

How do DIN 2353 single-ring or double-ring fittings achieve sealing?

Answer: To understand how they achieve a nearly perfect seal, let me tell you the principle of operation of each befitting independently. A noise 2353 fitting is handed with a ring that serves two purposes to induce the grip to hold the connection in position and to induce the seal. In addition, a noise 2353 single ring fitting has a hexagonal nut that, as it’s tensed with a standard wrench or spanner, deforms the ring into a conical shape( biconical fitting) until it’s clamped and fixed on the tube or pipe of the system, therefore generating a veritably secure grip and a virtually perfect seal.

What should you keep in mind when using your DIN 2353 or double ring fitting?

Answer: Although a noise 2353 single-ring and a double-ring fitting are generally veritably dependable and largely durable couplings, there are certain effects to keep in mind to ensure that you won’t have any problems when using them.

- Rings and nuts tend to wear the most, so it’s a good idea to keep many reserves on hand.

- Be careful with them. However, if it were to fall off by mistake, the rings could fluently be lost, If you be to remove it to replace it.

- Pre-loading the nut may be a good idea before completing the final tightening on the pipe or tubing to ensure proper grip and sealing.

- Be sure to always use noise 2353 and double-ring fittings with the proper sizes and pressure conditions for the rest of the system. This will help your fittings from breaking and leakage problems. noway mix millimeter mm measures with inch measures.

- Although it’s veritably delicate to have leakage problems when using a noise 2353 or double-ring fitting, it’s always a good idea to perform pressure tests to ensure proper installation.

Conclusion

We hope that we have cleared all yours questions about Hydraulic Fittings. If you have any queries about the “Hydraulic Fittings“ you can contact directly in my contact us page. Thanks for reading.

Related Posts