What is a Coil Spring?

A coil spring is a helical-formed mechanical device fabricated from wound metal. They save ability mechanical power and launch the energy to take in shock. Coil springs are made with the aid of winding a strand of wire with the use of continuous turns to shape a helical coil. The method transforms a strand of twine into a helix that is capable of storing electricity.

The varying sizes of coil springs are used to lessen surprise and strain on a surface by permitting deliver. They change their shape when an outside pressure is applied to them however, they return to their unique shape while the force is removed. The power of a coil spring is saved and recovered whilst the spring returns to its normal shape, which depends on the quantity of pressure implemented.

When coil springs are conserving weight, they reduce in length beneath the implemented force. It shops mechanical power because of the compression. As the pressure is eliminated, the coil spring expands and releases its saved mechanical energy.

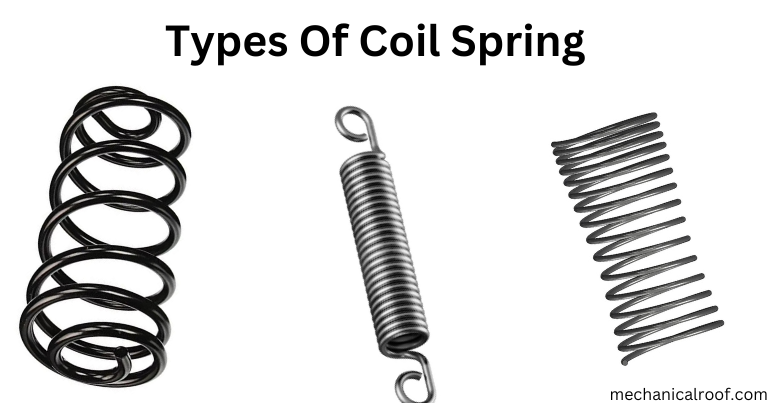

The 3 important kinds of coil springs are compression, extension, and torsion, each of which plays a one of a kind function. Of the 3 fundamental types, compression springs are the maximum common, that are produced by using hot or cold winding of spring steel. They are able to soaking up pressure and offering resistance when they may be compressed.

Rust and environmental elements cause pressure on coil springs, which results in early failure. As a further degree of safety, they may be powder, epoxy, or polyester covered, with a few being electroplated with zinc or nickel.

Types Of Coil Spring

Springs may be coil and non-coil, which is decided through their design. Coil springs have a coiled look and are crafted from a strand of steel that follows a helical route to create the coil. The most common approach to manufacture coil springs is to wrap or wind spring fabric around an arbor and coiling point.

Each form of coil spring has features that distinguish it from the opposite kinds. The preferred rule for coil springs is that they’re designed to endure some shape of strain, which may be compression or extension.

- 1- Volute Spring

- 2- Arc Coil Springs

- 3- Variable Coil Springs

- 4- Torsion Coil Springs

- 5- Compression Springs

- 6- Extension Springs

1- Volute Spring

Volute springs are crafted from flat cloth that has been coiled around an arbor into the shape of a volute, which is the shape of a spiral scroll. They resemble a tube with a small end with some sort having small ends at each end. Once the sheets of material are coiled, the spring is heated, which affects the distance that determines the shape, dimensions, and cargo homes of the spring. The flat sheets overlap and guide each other radially during compression, which will increase the stableness of a volute spring.

2- Arc Coil Springs

Arc coil springs, also called bow springs, have an arched form that does not run straight from cease to quit but has a curve in the center within the shape of the bow for a bow and arrow. They had been at first designed for use in twin-mass flywheels for power trains. Force is applied at both ceases of the spring to drag objects together.

3- Variable Coil Springs

Variable coil springs have distinctive distances between the turns of the spring. The versions inside the distance among the turns change the spring’s compression at each of its turns. When a variable coil spring is compressed, the pounds of power exchange with every compression or at an exponential curve. The design of variable springs effects in less complicated unlocking, stepped forward balk electricity storage, dampening, feeding, breaching, and lockup.

4- Torsion Coil Springs

Torsion coil springs are flat spiral coils that are used to use torque or save rotational power. They shop and launch rotational strength through torque, which causes the spring to rotate on its axis to use or withstand a load. Torsion springs are attached to components with a view to rotate around their axis. In most instances, they’re very tightly wound however additionally have variations that have pitch to lessen friction among the coils.

As with maximum springs, torsion springs may be located at angles, horizontally, or vertically to be rotated along or towards their axis. When a torsion spring is circled, its coil is wound tighter to shop or launch energy. Common uses for torsion springs are mouse traps or self-remaining display screen doors.

5- Compression Springs

Compression coil springs are wound helically so as to withstand axially implemented force. They are a totally powerful spring that is manufactured in huge sort of sizes from ones for retractable pens to ones used on automobile suspension systems. There are diverse forms of compression springs, which include helical, conical, or volute, barrel, and hourglass.

- Straight Coil compression springs have coils with the same diameter at some point in their length. They are the maximum not unusual shape of compression spring.

- Hourglass compression springs are tapered within the center to a smaller diameter than the relaxation of the coils. The layout of hourglass springs continues them focused in a bigger diameter hole. They have some of the benefits of conical springs with the brought benefit of being symmetrical.

- Barrel compression springs have small diameters on their ends and larger diameters in the center. Trouble with not unusual compression springs is their tendency to buckle or bow whilst strain is applied. Barrel compression springs prevent buckling due to the fact their form makes them greater flexible, take in less area, and are able to become distinctive designs. Since a barrel compression spring is wider in the middle, strain is sent differently, creating a better balance.

6- Extension Springs

Extension springs are like compression springs however are tightly wound and loaded with tension. They have hooks or loops at either quit to apply pull pressure. Extension springs are attached at each end to the components. When the additives circulate aside, the extension spring attempts to carry them lower back collectively. The initial tension in the spring determines how tightly coiled it is and may be modified to fulfill the desires of an application. In essence, they provide go go-back force for additives that have extended to the actuated role.

Types of Coil Spring Ends

There are four unusual forms of coil spring ends: closed, open, rectangular, and pigtail. It is important to choose the proper give-up to suit a coil springs utility.

Closed End

The closed-stop model of coil springs is the most unusual shape. In closed-stop coil springs, the pitch of the top of the spring is flat with its tip in touch with the adjoining coil. The close design gives a strong coil spring that can stand flat on its own.

Square End

Square stop coil springs are a form of closed cease coil spring wherein the stop of the spring has been ground. They have more deflection than open-end coil springs.

Open End

Open-stop coil springs are continuous springs wherein the coil continues on its pitch. They are every so often called tangential coil springs. Open-stop coil springs are utilized in programs where the spring will sit down on a seat, which is commonplace in in-vehicle applications. In order for an open-stop coil spring to be used, it ought to have a seat upon which it is able to stand.

Pigtail Coil Spring

In a pigtail coil spring, the spring’s closing coil has a smaller diameter than the relaxation of the coils. The smaller diameter of the pigtail give up of a coil spring makes it feasible to connect it to a mechanism with the usage of a screw or bolt.

Uses Of Coil Springs

Coil springs are a completely broadly used device that can be located in a by no means finishing an array of additives, machines, devices, contraptions, and motors. They are a vital part of scientific devices, cars, heavy lifting systems, and small sensitive tools. Their capacity to store and launch strength is necessary for the guide and efficient operation of programs.

Uses in Doors:

Coil springs are extensively utilized in doorways to hold a door open or near it robotically. They are a critical part of the hole and closing of garage doors on the grounds that they endure the load of the door and preserve it in the vicinity until it’s miles pulled or moved to be closed. Coil springs for doors are designed to suit the load and length of the door to avoid failure. In automated doors, they exert resistance to keep doors closed but launch their anxiety whilst the open sensor is activated.

Automobile Uses:

In trucks and cars, coil springs are an essential part of the suspension system coordinated with the struts and shocks. They soak up effect from the street, support the car’s weight, make certain a smooth experience, and maintain the wheels in touch with the street. In smaller sorts, they keep the hood open and manage the motion of the valves of the engine. Coil springs are the purpose that automobile seats are cushty.

Firearms Uses:

Coil springs are a necessary a part of the function of a firearm inside the shape of mag springs, cause springs, and recoil springs. When utilized in detonators, they’re flattened and held in a compressed country till precipitated. Coil springs are used because of their reliability and capacity to resist the constant use required from a loaded weapon.

Springs in Construction:

Coil springs are a critical part of all production projects from being anchors for brand spanking new creations to reinforcing present foundations. They offer help for sidewalks to govern motion and movement. Coil springs are covered in protection launch valves to open and near pipelines and launch pressure in a machine. They are used as help for railroad cars and engines as well as for bridges and overpasses. In conditions in which vibrations or motion can harm a utility, they’re used as dampeners and sound-absorbing devices.

Residential Use:

The common domestic has a huge range of coil springs in nearly every room. They are discovered in mattresses, chairs, and couches to offer aid and reduce the impact on the furnishings. Modern kids’s toys use springs to prompt them and keep them going for walks. They are a critical part of switches, storage door openers, cabinets, appliances, and a limitless wide variety of programs. In many ways, homes are very depending on coil springs for easy and convenient dwellings.

Springs in Pens:

Compression coil springs are used to push the ballpoint of a pen out and go back it. Springs for ballpoint pens must have enough elasticity to compress to a solid top. For it to work well, the spring ought to have a free index and enough coil in proportion to its unfastened length and twine diameter. The extra open its diameter and more coils, the lighter the spring will be.

How Coil Springs are Made?

Coil springs are elastic gadgets that shop and launch mechanical energy and are synthetic with the use of a whole lot of substances, which might be selected according to the design of the spring. They can be a closed-wound or open-wound with close-wound coil springs having coils that contact even as open-wound coil springs have open ends.

The sort of cloth and method used to fabricate coil springs depends on whether or not the manufacturing run is small or excessive volume with small runs being finished on a lathe while large quantity runs are produced on computerized coiling machines or computer numeric managed (CNC) machines.

Coil Spring Materials

The maximum common metals used to produce coil springs encompass excessive and medium carbon metallic, chromium vanadium steel, chromium silicon steel, various grades of stainless steel, copper alloys, and nickel. The choice of metallic is dependent on the utility in which the coil spring will be used. Since not all springs are products ofa cord, the metal for the manufacture of coil springs cabere available in exceptional forms to fit the type and style of spring.

In a few manufacturing instances, metals are introduced as metallic bars that are heated and drawn into twine to the proper diameter.

Coil Spring Manufacturing Processes

Stress Relief

When a spring is synthetic, its twine is stretched and coiled with pressure to make it take the form of a spring. During the coiling manner, the molecules of the metal have their natural stability disturbed leaving the spring with residual stress. If the residual strain is not relieved, a spring will have defects, cracks, and a brief lifespan. Stress comfort brings the molecules of the wires of a spring back into equilibrium.

Stress remedy is carried out by way of heating a spring to a degree below its deformation degree such that the cord becomes malleable but does not soften. Once the heating manner is finished, the spring is permitted to very slowly go back to room temperature, and the molecules rearrange.

Alloy steels, including chrome silicon or chrome vanadium, are pressure relieved between seven hundred° F and 800° F (371° C and 426° C). The excessive tensile energy of chrome silicon requires that it endure strain alleviation for one hour or greater. Stainless steel 17-7 is stress relieved at 900° F (482° C) for over an hour, as nicely. Stress comfort at better temperatures and over longer durations of time appreciably lowers the inner stress of a spring.

Hot Winding

Mandrel – The heated metallic is coiled round a mandrel in the identical method as bloodless coiling however with greater care. A CNC system controls the rotation of the mandrel and the pitch distance.

Wire – Wire for warm coil winding may be thicker, with thicknesses varying between 3 inches or seventy five mm up to 6 inches or one hundred fifty mm. The wires for hot winding are heated to 1700° F, that is why producers can paintings with larger diameter cord.

Cooling – The immediately subsequent step for decent coil winding is to chill the wound coil as quick as viable, a process called quenching. Several one of a kind techniques are used to quench metallic elements with oil being one of the more famous. The purpose of cooling is to harden the coil’s steel and reduce the formation of thermal and transformational gradients that would result in cracking.

The severe cooling modifications the crystalline structure of a metal component and freezes the changes, which makes the metallic tougher. When cooling begins, a vapor blanket forms across the component because the first stage of the manner. The vapor blanket is removed via heating the quenchant, after which the convective degree in addition removes warmth to cool the component.

The recognition of cooling or quenching oil is because of how unexpectedly it quenches a part in comparison to other techniques. A great deal of care has to be taken in the course of the quenching process, which may be very closely monitored to ensure the produced coiled spring performs up to expectancies.

Cold Winding Process

Heat Treatment – Cold winding starts with warmness treatment of the twine or running to reach its highest electricity level. The process of cold winding can only work with wires that have a diameter of 0.75 inches or 18 mm or much less.

Mandrel – A mandrel is certainly one of two strategies used to supply coil springs. The manner can be completed using a lathe, winding machine, or hand crank gadget. A manual mechanism is used to align the twine to the desired pitch, the distance among the wires because it wraps.

Computer Numerical Control (CNC) – CNC spring coiling machines are extra complicated and complicated than the traditional mandrel layout and entail a set of components that efficaciously feed, wind, and configure the coils.

- Feed rollers pull the cord from the reel and feed it into the cord guides.

- Block guide ensures that wire keeps to the coiling point. The groove of the block guide is the precise same diameter as the twine.

- The arbor is the portion of the machine that winds the wire as a mandrel does and has 3 points of contact.

- The pitch device is programmed to position the wire on the proper pitch to meet the layout. It slides up and down the arbor, transferring alongside the sloped floor.

- Wire courses are flat with one-of-a-kind sizes of grooves to match the feed rollers however they are not exactly in shape the wire lengths are inside its variety.

- The coiling point pushes the twine into its coiled shape by deflecting its trajectory. The deflection point is programmed into the CNC system and determines the deflection perspective.

The cutter slices the twine whilst it has reached its preferred period. It can be positioned above or underneath the arbor relying at the CNC machine’s design.

Finishing a Coiled Spring

The completion of a coiled spring depends on its design, which could range consistent with the way it should be shaped, and lined, have its pitch set, and how it is reinforced.

Grinding – Some springs require grinding to flatten their ends to fit their design. The grinding manner is completed manually or automatically relying on the manufacturing method. For guide grinding, the coil spring is held in the area by way of a jig and ground using an abrasive tool. With computerized grinding, the spring is held in the area even as both ends are floor according to system programming. Some lubrication is important for the grinding process to keep the metal cool and convey away the waste.

In many cases, the grinding of a spring is vital so that it can fit into a utility or be capable of taking a seat flat. The technique makes it viable for the spring to face upright.

Shot Peening – Shot peening consists of impacting the surface of the coiled spring with a shot, small spherical steel balls, glass, or ceramic debris. The impact of the many photographs produces a compressive pressure layer and modifications the coil springs mechanical homes. The barrage of pictures smooths the floor of the spring and compresses it.

Set Pitch and Length – To set the pitch and period of spring, it’s far compressed until the wires contact. This can be repeated till the required dimensions are executed. Measuring the pitch can be tough. Initially, the pitch can be expected by way of measuring the distance between the loops of the spring. It is a clean method but now not the maximum correct. The exceptional approach for buying the genuine pitch is to use a spring pitch formulation, that is available in pc packages.

The length and the pitch may be visible within the diagram. There are one-of-a-kind views concerning the pitch of coil springs. Many specialists agree that specifying the wide variety of lively coils is a higher degree than pitch.

Applying Coatings

Coatings are carried out as a shape of protection against corrosion seeing that most of the metals used to provide springs are susceptible to the outcomes of the factors. The complete floor of the spring is covered by the usage of diverse methods, along with spray painting, dipping in rubber, or electroplating with zinc or chromium.

- Zinc coatings offer exceptional corrosion resistance without the hazard of hydrogen embrittlement. The zinc is implemented in a solution of resin this is sprayed, dipped, or spun onto the floor of the coil spring.

- Electroplating is one of the most common paperwork for making use of a coating in view that it’s miles low value and very powerful. Materials that may be implemented through electroplating include zinc, chromium, tin, and nickel, with tin and nickel used where electric conductivity is essential.

- Powder coatings are available in a whole lot of colors for corrosion resistance and are usually used on big springs since the thickness of smaller springs can be too excellent.

- Pre-plated wire is used to fabricate coil springs as the raw fabric. The galvanized cord is the maximum commonplace form of pre-plated twine as it has excessive corrosion resistance. Pre-plated twine ensures that the complete surface of the spring has been fully handled.

- Plastic coating is a flexible material lined on springs for expanded corrosion protection. The unlucky aspect of plastic coating is that it could be damaged by using constant compression and different elements.

Metals Used to Make Coil Springs

The first step in the manufacture of coil springs is the choice of the best steel from which to manufacture the springs. Critical to the selection system is the tensile electricity of the metal such that it conforms to the demands of the software. The majority of springs are crafted from metal alloys due to their abundance and fee. Copper and nickel alloys also are used for particular packages.

The sort of metal selected to provide a steel spring is so that you can maintain and launch the necessary mechanical electricity for a protracted period without failure. The most important homes of nicely made coil springs are their ability to deliver force among contacting surfaces and being capable of taking in surprise and pressure.

Use materials to make a coil spring given below:

- High Carbon Steel

- Chromium Vanadium Steel

- Chromium Silicon Steel

- Stainless Steel

- Silicon Manganese Steel

- Copper Based Spring Alloys

- Nickel Based Spring Alloys

Conclusion

We hope that we have cleared all yours questions about Coil Spring. If you have any queries about the “Coil Spring“ you can contact directly in my contact us page. Thanks for reading.