What are Bucket Elevators?

Bucket elevators or grain conveyors are used to move bulk materials. The use of bucket elevators is specially giant in commercial agriculture and mining, and several specialised organizations manufacture bucket elevators and components. The bucket elevator includes a double-strand curler chain that lifts hundreds in both horizontal and willing guidelines. These bucket elevators characteristic a sturdy layout and coffee power necessities, making them best for transporting hot and abrasive materials. Additionally, the blade does not tilt to release fabric. They stay within the shipping role.

These conveyor, also called bucket conveyors, are utilized to move materials and merchandise vertically from one floor of a facility to some other place. Although the terms “elevator” and “conveyor” are every so often used interchangeably, there are differences inside the production of bucket system.

The maximum not unusual call for those gadgets is bucket elevator. It uses a sequence of buckets which can be moved vertically through centrifugal force to move items or materials up and down.

In evaluation, bucket elevators flow hundreds at acute angles and are similar to vertical conveyors. The foremost distinction between the two is that cup conveyors are less complicated and are used to move sensitive items or products.

The buckets have curved ends in an effort to pull and keep gadgets, and that they rotate to maintain them upright always and save you spills. For example, bucket elevators can shipping ore, fertilizer, and grain. A easy vertical bucket elevator alternatives up bulk materials and dumps them at the top, then sends the empty bucket go into reverse to acquire new hundreds. The unloaded items are sent down chutes that are related to garage boxes, packaging bags, or different gadgets. With a bucket elevator, cloth managing is completely mechanical and calls for no human intervention apart from staring at the elevator’s operation and adjusting settings.

More superior bucket elevators may be programmed to transport along a horizontal tune in addition to drop off goods at numerous durations. In popular, elevator functionality is protected for safety reasons to prevent humans from turning into trapped interior a transferring elevator. This protection is in particular vital if the bucket is hooked up to a series in place of a strap. This is because the chain can get caught on free apparel, hair, or frame elements, inflicting severe harm to each the operator and bystanders.

Types of Bucket Elevators

The motive of non-stop bucket elevators, not like different bucket elevators, is to move delicate or mild materials. There aren’t any gaps among the buckets to prevent spills, and they pass at a reasonably gradual velocity (three to 5 toes according to 2d). The inlet fills each bucket in my view (no drilling is accomplished) after which the buckets in order that the product is affected simplest by means of gravity. This lets in you to deal with fragile or brittle substances and forestalls airflow and product harm.

Depending on the state of affairs, they can be in S, Z, or C shapes, and are to be had in plenty of shapes and ability classes. They are used in heavy-duty applications in mining, the plastics enterprise, and other sectors that require little motion.

1-Positive Discharge Conveyors

Positive Discharge Conveyor run on additional sprockets that push cloth out the discharge stop, making it a completely unique sort of centrifugal conveyor. Therefore, they pass extra slowly (2 to four feet in keeping with 2nd), preventing immoderate spillage and material harm. Each producer has a completely unique design for the cups on those conveyors, making them large to catch up at slower speeds. It is especially beneficial when maintaining product integrity is a pinnacle precedence, together with whilst transporting cereals, nuts, dried fruit, and different comparable products. However, they are regularly more luxurious than different bucket elevators and are to be had in a lot of configurations and sizes.

2-Centrifugal Bucket Conveyors

The centrifugal bucket conveyor makes use of centrifugal pressure to transport free-flowing fabric. To optimize centrifugal forces, equally spaced buckets at the chain chew into the fabric at the inlet, generally right away after the pinnacle rotation of the chain, earlier than discharging the material through the opening.

These buckets are surrounded by way of a steel casing that forestalls material from escaping everywhere aside from at the discharge quit, permitting any final fabric to fall to the bottom and restart the conveying method. It can travel as much as 350 ft per minute and has a weight potential of as much as 100 kilos consistent with a cubic foot.

Suitable for both low and high speeds. Some variations of centrifugal elevators can journey up to at least,000 feet in line with minute, but those are handiest suitable for light-weight materials. Centrifugal bucket elevator paintings are satisfactory with pleasant substances and are appropriate for high-velocity programs, making them the preferred choice for grain, mineral, sugar, and chemical programs.

3-Chain Bucket Elevators

Chain Bucket Elevator can be used successfully for dry paintings despite numerous put on and tear elements. However, for dry paintings, thick grease need to be applied to lessen the impact of sand. Their competencies are constrained best with the aid of the scale of the bucket they can deliver. Certain variants can combine the roles of elevator and conveyor belt, allowing loading and unloading at specific points alongside the path, presenting clean advantages.

Chain bucket elevators benefit from conveyor belts as they can ship heavy loads and lift materials vertically. The specific shape of the bucket affords excessive balance and occasional chance of spillage. A chain bucket elevator makes use of chains to drag a bucket from factor A to factor B. The looked-after cloth is lifted using a series bucket elevator and returned to the primary circulation.

The sorted material is lifted by way of a sequence bucket elevator and again to the main circulation on a C-fashioned tune. The Z-stroke and Z-fashioned music of the bucket chain elevators are intended to return the looked-after fabric to the mainstream.

Chain bucket elevator includes an inlet hopper, vibrating conveyor, bucket, gear motor power, inspection hatch, and go-out chute. A geared motor continuously moves the bucket while it’s far attached to the chain. The bucket is poured into a distribution chute on the pinnacle of the device. There is a drawer at the lowest for easy cleansing. The chain may be adjusted manually.

4-Belt Bucket Elevators

For lifting ore, whether or not wet or dry, belt bucket elevators are the most commonplace equipment. In moist operation, they provide advantages over chain bucket elevators in that they do no longer require complicated or luxurious lubrication and they revel in less floor wear and friction. However, the ability of a specific belt is confined by way of its adhesion to the head pulley. This is advanced with the aid of wrapping the pulley in a non-slip cloth.

They occupy significantly less floor space than willing conveyors and might raise skinny pulp. If upkeep are required, it is critical to have a way to drain the elevator trunk, preferably someplace where the cloth may be speedy washed off or conveyed to any other elevator.

5-Bucket Lifters

Bucket Jack (BL) is used to transport fabric from factor A to point B using one or extra buckets. Bucket lifters are specifically designed to raise smaller substances than chain bucket elevators or belt bucket elevators. Bucket jacks are an smooth and less expensive way to transport matters from one place to every other.

The Bucket Lifter includes a geared motor, one or more buckets, a chain or belt, and a metal frame. A backside loading station ensures accurate dosing of the bucket. Tilting it lifts the bucket and empties it. After a positive quantity of time, the bucket tilts to the ground and is ready for the subsequent filling. If the bucket lifter has more than one bucket, they all return to the lowest for my part after emptying. The bucket lifter is manufactured from stainless steel or painted metallic and has a stable body structure.

6-Multiple-Discharge Bucket Conveyors

Multi-Discharge Bucket Conveyor can be used to raise and ship products to loads of places, inclusive of: B. Supply a huge wide variety of bagging or packaging machines nearby. This bucket conveyor design permits for many feed points, making it a extra cost-powerful option than more than one conveyors.

7-Indexing Bucket Conveyors

Intermittent Bucket Conveyor has a special form and purpose. A unique quantity of product is despatched from every bucket to an index bucket conveyor, which unloads the product into a packaging device.

8-Skid Steer Conveyor Buckets

Skid Steer Bucket may be used to fill up litter, lay down mulch, or sand your panorama property with a facet discharge bucket. These buckets often come in exceptional diameters in step with the model. Compact conveyor fashions are to be had in different widths and in sand or sawdust variations. Mulch is every other utility of the sawdust paradigm. All of those gadgets provide benefits to users. Everything is managed via a joystick within the cab and included in the system’s regular waft hydraulics.

Skid steer loaders are agitators with hydraulic motors for putting sand. Three direct-drive vehicles are mounted on facet discharge buckets, all operated with the aid of fashionable hydraulics and in my opinion controlled by means of stroller switches on the facet of the cab. Depending on where the fabric wishes to move, the operator can discharge the cloth to the left or right. In this sand version, a heavy-obligation 12-inch-huge belt discharges the material (left aspect in this example). The waft of material to the bed, aspect of the house, or solid can also be adjusted with the usage of a discharge restrictor, which is an adjustable plate that moves up and down. The frame shields the hydraulic motor.

This hydraulic motor is an agitation motor and the alternative one works constantly while hydraulic motors force the belt. These shovels can also be used to load substances from the front. The slicing-edge has a weld that customers can use to load mulch, sand, sawdust, or straw. The side discharge bucket is prepared with an alternative belt put on pads and screws for normal flow hydraulics. As the belt constantly turns, fabric accumulates and wears down on those replaceable plate bolts. Both the straw and sawdust configurations have levelers or levelers that permit the cloth to fall lightly onto the belt and discharge to the desired area. The sand design has an agitator.

9-Horizontal Elevators

In assessment, horizontal elevators have no cables. Instead, they use linear motor technology evolved for magnetic levitation trains for a ropeless machine. As a end result, many automobiles at the tune flow up one shaft and down another in a single continuous loop, similar to what trains do on a railway community. The major advantage of this method is that the horizontal elevator gadget can pass as much as 50% greater weight in one shaft than a conventional elevator.

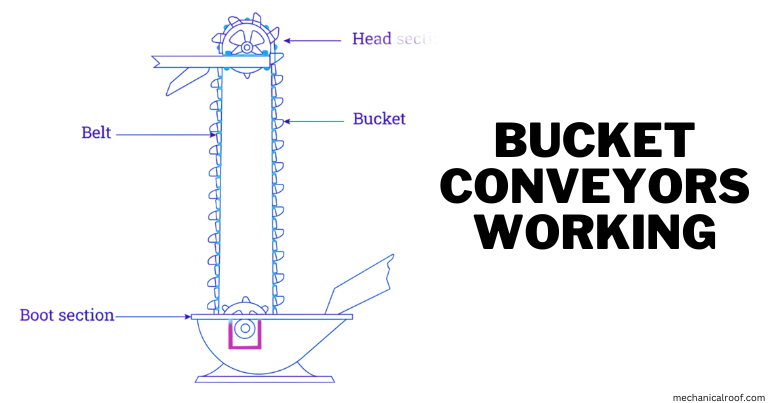

Bucket Conveyors Working

Bucket elevators use reciprocating buckets to transport objects (normally aggregates or bulk substances) vertically. A conveyor belt includes a network of troughs or cups that move vertically even while maintaining a flat floor to save you from spillage of contents. The fabric is located at the “push” or the front of the conveyor belt and every cup is emptied routinely at the unloading point or at the end of the run.

This vertical conveying approach is brief and automatic because the equal cup used to accumulate the fabric is likewise used to empty it. Additionally, whilst well synthetic, these machines are durable and effective. However, the design depends on the fabric being transported and the peak required for delivery. Ideal for transporting dry, light, or powdered materials. Wet or sludge-like substances are normally avoided as they may accumulate in the bucket and impair waste remedy potential.

TheBucket Elevator, like most other heavy system, is meant for non-stop use. The start-forestall operation will increase the danger of spills and might harm equipment and decrease efficiency. Companies can operate their bucket elevators for a fixed amount of time each day, or surely constantly if their processing desires are sufficient. The bucket elevator has an emergency prevention setting that allows the user to stop it if trouble takes place. Some merchandise are sensitive to obstructions that indicate something is caught within the device and will close down right now.

Applications Of Bucket Elevators

- Cement: Although centrifugal bucket elevators are favored for transporting completed cement and other less abrasive materials, non-stop bucket elevators are frequently the primary preference for cement agencies handling enormously abrasive substances.

- Glass: In this example, the plant does no longer require a centrifugal elevator, as a non-stop bucket elevator is higher acceptable for handling abrasive materials that do not degrade.

- Pulp and Paper: Continuous bucket elevators are suitable for dealing with massive quantities of abrasive substances together with wooden chips and ash, while centrifugal bucket elevators are pleasant and applicable for coping with small quantities of non-abrasive substances such as fuel.

- Centrifugal bucket elevators are suitable for transporting non-abrasive, non-brittle materials within the mining and mineral processing industries. In evaluation, continuous bucket elevators are best for dealing with different materials.

Advantages of Bucket Elevators

- Innovative Design: Buckets are available a whole lot of sizes and styles depending on your overall desires. Additionally, many bucket elevators are designed to have a far smaller footprint than traditional conveying technologies. This small length saves vast amounts of energy and saves critical production and system space. Therefore, bucket elevators can often be customized to healthy individual requirements and assignment specs. Additionally, many materials can be used to manufacture bucket elevators, which include stainless steel, carbon steel, and many others.

- Ease of transportation: A bucket elevator’s ability to move gadgets substantially quicker is possibly its best benefit. Cups additionally take care of substances a lot extra carefully than workers. In phrases of transportation ability, manufacturing facilities with non-stop bucket elevators can greater without difficulty delivery huge portions of goods, giving corporations a bonus over their competitors.

- Cost-effective: To make certain that tasks are finished on time and within finances, many business and manufacturing centers constantly compare expenses and overheads. Of direction, that is also based totally on the additional benefits of bucket elevators. This is a great technique to higher control your projects as it’s miles a weatherproofing system that could handle massive volumes extra successfully. Bucket elevators also are very useful in streamlining processes and may save businesses a lot of money. Bucket elevators are utilized by many production and business groups to satisfy many of their transportation desires. With proper maintenance and normal cleansing, this machine can remaining for a long term, making it an exquisite investment to your facility.

- High Capacity: Depending on the hopper or bucket decided on by the user, the elevator’s sustained centrifugal force can flow bulk materials. Additionally, bucket elevators are extraordinarily sturdy, so there’s no chance of liquid spills. In this manner property damage can be prevented and the bucket elevator can stay upright.

- Weatherization: Not finishing obligations may be time-eating, pricey, and exertions-in-depth. Most bucket elevators function in all climate conditions, regardless of the assignment or transportation necessities. This resiliency guarantees that inclement weather does now not motivate product delays or outages.

Disadvantages Of Bucket Elevators

- When compared to similar conveyors, the installation price is at the better aspect.

- The user have to continually take note of preservation tactics. If users overlook renovation, they might must cope with an difficulty.

- Although it’s far hard, one need to preserve a ordinary take a look at on preservation.

- If one bucket fails in a bucket elevator machine, it may additionally be hard to handle the remaining buckets.

- Fibrous fabric sorts cannot be treated through bucket elevators because they need help to top off bucket area and are vulnerable to wear and strain because of their nature.

Conclusion

- Equipment abnormalities ought to be reported to the correct personnel and all relevant records recorded inside the equipment records. Unusual sounds or odors, immoderate wear, harm, or malfunctions are signs and symptoms that something is wrong.

- Make sure all guards are installed and in the correct circumstance.

- Never use a device with worn, broken, or damaged parts.

- Always follow the producer’s advocated adjustments before they’re needed to prevent harm or put on.

- Track all modifications, lubrication, preservation, and inspections. Records should consist of the date, materials used, circumstance of each element, and signature of the person who serviced the bucket elevator.

- Turn off, lock, and tag gadget controls before inspection, preservation, lubrication, or adjustment.