What Is Slotting Machine?

A Slotting Machine is a reciprocating system that is specifically used to create horizontal, vertical or flat surfaces. A slotting system is especially used for reducing flat surfaces, forming surfaces and keyways and so on. And is appropriate for unmarried or small batch production. A slotting machine is a gadget tool this is used to remove undesirable cloth chips from a workpiece to provide splines, grooves and so forth. Here the ram (attachment device) moves backward and forward whereas in a forming gadget the ram moves horizontally.

A forming machine can be considered as a vertical forming machine as each are very comparable in lots of ways. The forming gadget is a totally old type of system, invented with the aid of Brunel. The device we use is a single point slicing tool fabricated from excessive pace steel.

Slotting machines are used to mill grooves, wedges and slots of various shapes to create inner and external normal and irregular surfaces, as well as for milling internal and outside gears and profiles. Slotting machines can be used for all types of operations in which vertical movement of the tool is considered crucial and useful.

Working Principle Of Slotting Machine

The working of slotting device is much like planer device but the essential difference is that planer machine works horizontally and slotting machine works vertically.

Now the plunger is hooked up to the crank and the crank is connected to the tools. So if we increase or decrease the equipment velocity the rotation of the crank will growth or decrease respectively. And this will make the plunger move up and down.

Now we have linked the paintings table and manually moved the ram towards the paintings. According to the ram we need to regulate the work desk and clamp it. When we offer power according to the gear the crank will rotate and the crank and plunger can be linked and the plunger will move up and down.

There is a cutting stroke during shutdown (RAM is going down) however no cutting during energy up or recuperation. If you want to cut into a couple of sections, manually guide it to the work desk and reduce as wished.

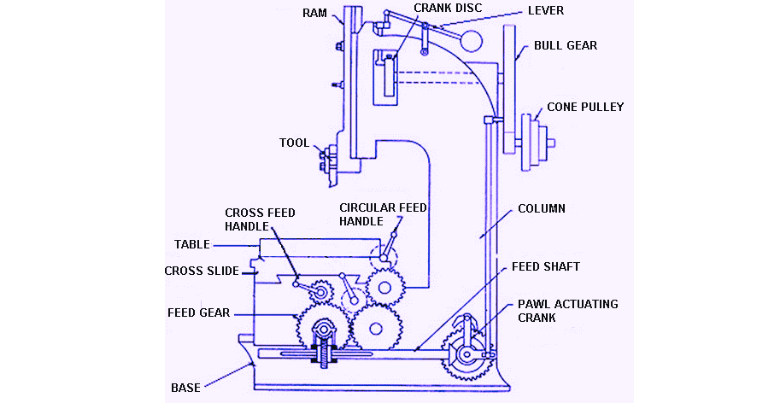

Parts Of Slotting Machine

- Base

- Column

- Saddle

- Cross-slide

- Rotating or Circular table

- Ram and tool head

- Ram drive

- Feed drive mechanism

• Base: The base is solidly built to withstand all of the retarding forces and the full load of the tool. The pinnacle of the mattress is precisely machined to provide guideways on which the saddles are connected. These are perpendicular to the front face of the column. Usually they are product of solid iron.

• Saddle: Always connected to a guideway, it is able to be moved manually or motorized in the direction of or far from the column to make certain excessive quality longitudinal movement.

• Cross slide: The pass slide is continually hooked up on a saddle manual and may circulate without delay parallel to the surface of the column.

• Ram and tool head: The ram slides on courses installed at the front vertical surface of the column. It has grooves for lifting curler adjustment. The ram feeds the device installed at the decrease end of the tool head.

• Ram force: It converts the rotary motion of the motor into reciprocating movement of the ram within the vertical plane. Idle time can also be reduced via decreasing the cutting speed or ahead stroke speed and growing the reverse stroke speed.

• Pillar: The vertical critical rigid detail to the proper of the floor is the pillar. It serves the following capabilities: It houses the drive for the ram which movements to and fro on its vertical front face. It additionally houses the desk feed mechanism.

• Rotary table or rotary desk: It can rotate on a movable carriage to circularly feed the workpiece and may be used to restoration the workpiece in clamps, furnishings, vice releases, and so forth. They are equipped with rotary feeders which can be operated manually or electrically. On a few machines the table may be divided into rows and indexed.

• Feed Drive: The desk may be advanced longitudinally or transversely, electrically or manually. It can also be superior in a circular fashion or turned around about a vertical axis. Intermittent feeding of the desk takes place on the begin of every cut or at some point of the forward stroke of the ram.

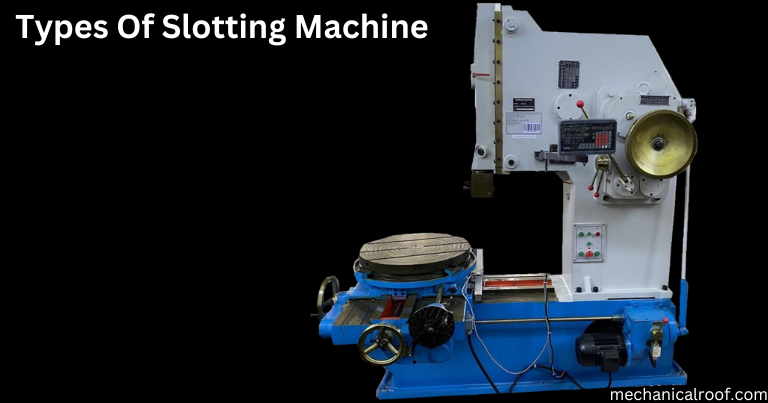

Types Of Slotting Machine

- Puncher Slotting machine

- Toolroom Sloting machine

- Production Sloting machine

- Keyseater Slotting machine

1. Punching & Slotting Machine

It is a completely strong and heavy gadget designed to put off maximum of the metal from castings and forgings. The stroke length of the punching and slotting device is satisfactorily long. It ranges from 2,000 meters to one,800 meters. The ram of the punching and slotting machine is normally pushed through the meshing of a spiral pinion with reduce rack enamel at the bottom of the ram. The pinion right here is driven by using a reversible variable pace electric motor much like a planer. Electric gears control the feed.

2. Tool Shaping Machine

It is a mild and speedy system. It is designed for very specific machining. This system lets in easy reducing and ensures specific finish. It can operate at very excessive velocity. Special devices permit the system to handle various duties on a production base.

3. Production Slitting Machine

Production Slitting Machine is a effective slitting gadget that consists of a heavy casting base and a heavy body, commonly along with parts. It is specially used for standard production operations.A slotted disc with a connecting rod is used for the reciprocating movement of the ram.This slitter employs a flywheel to prevent stroking at the stroke stop.

4. Key Setting Machine

Key setting system, also known as key setting system, is a special kind of slotter designed for slicing keyways.

The slot saddle is related to the vertical forming device. The difference is that within the slot saddle the slicing tool enters the workpiece from beneath and cuts with a downward stroke, while inside the forming machine the tool enters the workpiece from above and cuts downward.

Specification Of Slotting Machines

- Power Input

- Type of drive

- Maximum table drive

- Number of feeds

- Table feed

- Floor space required

- The maximum length of ram stroke

- Number of speeds

- The diameter of the Work Table in MM

- kW of motor

Application Of Slotting Machine

- It is used in many manufacturing devices to cut wedges, slots, seats, grooves of various shapes and to form everyday or irregular shapes. It can be used in any workshop where vertical movement of the device is required and is needed for manufacturing of diverse metallic items.

- It is used for light reducing, spline shafts, inner keyways, instantly daggers of internal spur gears, inner curved surfaces of circular elements, internal oil grooves and so on.

- It is likewise used for machining inner and external gears.

- Reaming and completing of non-circular holes bounded by a series of flat surfaces.

- Internal grooves and slots in rectangular and curved sections.

- Internal machining of geometric blind holes much like hexagonal sockets.

- Internal flat surfaces.

Advantages Of Slotting Machines

- It is a light-weight device.

- Cost powerful device.

- Low upkeep.

- Accurate floor end.

- The device used here’s a unmarried facet slicing device.

- Machine performance is increased.

Disadvantages Of Slotting Machines

- Skilled worker requires to operate.

- Rigid in construction.

Mechanism Of Slotting Machine

- Hydraulic Drive

- Variable Speed Motor Drive

Hydraulic Drive:

The speed motor drives a hydraulic pump, which feeds oil into the traces at consistent stress. A manage valve lets in the oil underneath pressure to glide alternately to each give up of the piston

. At the equal time, oil is released from each ends of the piston and back to the container. The piston is full of oil and is attached to the piston rod along with the ram, which actions the ram ahead at the same time as supporting the device.

The penetration of oil into both ends of the piston is carried out by using alternating among the motive force and control valves. As the piston actions forward and completes its stroke (forward and backward), the manage lever activates a valve that operates the manipulate valve.

The manage valve receives oil on the other aspect of the piston, reversing the piston pace. The period of the piston stroke depends on the location of the control lever. You can trade the duration of the ramp stroke through moving the manage lever to any function.

Variable Speed Motor Drive:

In this sort of slot gadget, the rate is performed by way of diverse gears in a gearbox, and the shaft rotates with the help of an electric motor. It turned into at first utilized in contemporary big slot machines.