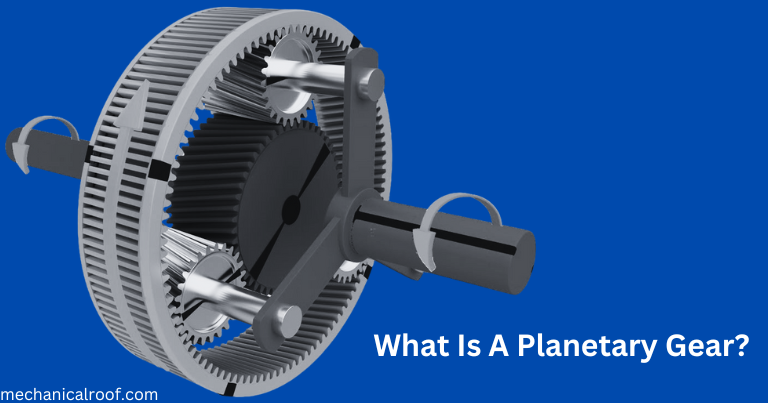

What Is A Planetary Gear?

A planetary gear is a kind of planetary gear in which 3 or extra gears, known as planets, rotate round a significant tools (solar gear) that acts because the input gear. The planetary gears surround the solar tools and planet gears and mesh with a ring equipment within the form of an inner spur equipment. Planetary gears are very strong due to their design and may be without problems transformed to different equipment ratios.

Planetary gears are reduction gears used in car and stale-avenue vehicle transmissions, wheel drives, and business conveyors. They are known for his or her excessive translatability, compact layout, and durability, making them best for uncommon and particular programs. The robustness of planetary gears is primarily based on the even distribution of load among the sun and planet gears. Planetary gears can manage greater torque and equipment ratios due to a couple of tools meshing.

Types Of Planetary Gears

Different styles of planetary gearboxes vary in overall performance, efficiency and versatility. Each kind can convert two input alerts into one output signal, making them complex to build and examine.

The counter-intuitive conduct of planetary gears makes them hard to investigate, however they are also captivating and interesting. They offer brilliant torque with corresponding stiffness and occasional noise in a compact footprint. Planetary gears are available in loads of shapes and designs, which is one of the reasons they’re so broadly used.

A short listing of planetary gears consists of:

- Single-stage

- Multi-stage

- In-line

- Offset

- Coaxial

- Right angle

- Harmonic drive

- Differential

- Simpson

- Ravigneaux

These 10 planetary gearboxes are only a small portion of the entire list of planetary gearboxes, which additionally consists of area of expertise gearboxes for particular and unusual packages. It is vital to notice that every form of planetary gearbox has blessings and disadvantages. Their use is decided by using how they meet the wishes of the utility.

Single Stage Planetary Gear

The Single Stage Planetary Gear consists of a sun gear, three planet gears, a service, and a ring gear. As the input shaft rotates the solar tools, the planet gears rotate the provider and output shaft. Gears of various sizes and exclusive number of teeth vary the output pace and torque. Single stage planetary gearboxes are utilized in transmissions of heavy machinery, business system and cars. Like maximum planetary gearboxes, single degree planetary gearboxes are used due to their compact design and weight.

Two Stage Planetary Gearbox

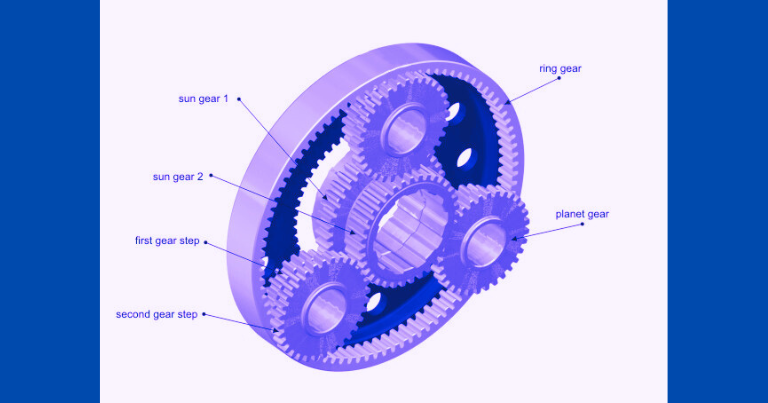

Multi-degree planetary gearboxes have or greater planetary gears to gain the specified velocity and torque. It has the same structure because the single stage planetary gearbox, but numerous more gears are delivered to the input shaft of the primary set, linked to the solar tools of the primary set. The first set of companies is connected to the second one set of solar gears and this pattern maintains for all the planet gears in the multi-degree planetary gearbox. Multi-degree planetary gearboxes are used in packages requiring high torque and more than one output speeds. They provide high equipment ratios in a compact, lightweight package deal.

Three-Row Planetary Gearboxes

In-collection planetary gearboxes, the enter and output shafts are aligned and consist of a unmarried sun gear and more than one planet gears contained inside the ring gear. The planet gears are established on a provider which rotates around the solar. The input shaft rotates a relevant solar gear which in flip rotates planetary gears which mesh with a ring equipment. Rotation approximately a crucial axis transmits energy to the output shaft. In-line planetary gearboxes are used because of their performance, torque density and coffee backlash.

Offset Planetary Gearboxes

An offset planetary gearbox is referred to as a parallel axis planetary gearbox. The input and output shafts are both offset or parallel. Similar to in-line planetary gears, offset planetary gears have a solar gear with a couple of planet gears hooked up on a carrier, which meshes with a hoop equipment. The output is not in keeping with the enter, however points in a different direction relative to the enter shaft. By well choosing the diameter and range of enamel on the idler equipment, the input and output shafts can be aligned on a not unusual axis.

Right-Angle Planetary Gear Sets

In a proper attitude planetary tools set, the enter and output shafts are located at proper angles to every different. The sun gear, planet gears, service and outer ring are all mounted in the same configuration as in different gear sets. The rotation of the planet gears transmits electricity to a proper attitude bevel tools linked to the output shaft.

Harmonic Drive Planetary Gear Set

Harmonic pressure planetary gears are also known as voltage wave gears and wave generating gears. They use a bendy metallic shell and a circular splined shaft to transmit torque. The components of a harmonic drive planetary gearbox are a round spline shaft and a flexible shell referred to as the shaft generator. In addition, the gearbox is prepared with an elliptical or round gear referred to as a flexspline. The enter shaft drives the wave generator, which deforms and generates waves that travel alongside the circumference of the shell. The generated waves mesh with the teeth of the flexspline, which rotates around the vital axis of the harmonic pressure gearbox.

The flexspline meshes with the outer ring tools and transmits electricity to the output shaft. Harmonic Drive planetary gearing has no backlash, high precision, and high torque density. This makes it best for programs wherein precision and repeatability are vital, including robotics and automation.

Simpson Planetary Gear Set

Simpson planetary gears have or 3 sets of planet carriers connected in collection with one solar equipment. Simpson planetary gearboxes have three ahead gears, one reverse tools, and one impartial tools and are utilized in three or 4 speed computerized transmissions. The transmission is named after Howard Simpson, a well-known innovator in car design.

The two planetary equipment units are interdependent thru a not unusual solar gear. The first equipment set is closer to the input shaft and synchronizes with the hoop of the second one tools set.

Ravigneaux Planetary Gear Set

Ravigneaux planetary tools is an development over the Simpson planetary equipment, together with two solar gears, ring gears, and two units of planet gears on a single service, making the Ravigneaux planetary equipment smaller, lighter, and less expensive. The suns are targeted along a commonplace axis of rotation and are unequal in size.

In the Ravigneaux planetary tools, the small sun equipment meshes with its set of planets, which in turn meshes with the outer ring tools. The large outer ring tools is attached to the planets of both planetary gears and meshes with the bigger of the two suns. A carrier with various radii holds the planetary equipment set in area and is hooked up to the force shaft. It rotates together with the solar equipment and ring equipment.

Differential Planetary Gear Set

In a planetary gear with differential, each gear rotates. It is a key detail of the transmission that drives the wheels of a vehicle. Originally, automobiles have been designed so that one wheel became driven while the opposite turned into loose to move. Although this approach of propulsion was effective, it turned into no longer secure, so a manner to force both wheels had to be determined.

The improvement of the planetary tools with differential required each wheel to have its own drive shaft. Multiple bevel gears with providers are used to interchange the path of rotation of the pressure shaft. The equipment set consists of a massive ring equipment, a provider, planetary gears, and a solar gear. The ring gear is attached to at least one wheel shaft and the sun tools is attached to the alternative wheel. This lets in the rotation of the drive shaft to be varied to pressure the wheels.

Planetary Gears

Planetary gears are driven with the aid of hydraulic motors, electric powered vehicles, or combustion engines. They are the most common shape of gear and are at once related or vital to precision cars. Planetary gears are very efficient at transferring power from the motor to the output.

Wheel Drive

Wheel force planetary gears are the handiest shape of transmission and may be related immediately to the wheels through the system housing. The service in a planetary gearbox with wheel drive is located in the gearbox. By connecting the gearbox at once to the wheels, the dimensions of the gearbox may be decreased.

Shaft Output

As with different planetary gears, the sun gear rotates the planets which might be housed in a carrier inside the shaft power gear. The ring equipment is fixed even as the provider rotates the pressure shaft. The gearbox housing is hooked up directly to the device and the output is the rotating shaft.

Spindle Output Gear

Spindle Output Gear is precisely the same as Shaft Output Gear, the primary difference is that the output is via a flange.

How Planetary Gears Are Made

Planetary gears are a means of converting reciprocating movement into rotary movement. They had been evolved through William Murdoch in 1781 for use in steam engines as a alternative for the crank used to supply rotary movement. A not unusual utility of planetary gears is speed reduction in confined areas.

The most essential and vital components of a planetary tools are the sun or imperative tools, numerous different gears called planets, the ring tools, and the planet service. The 4 components of a planetary gear make certain balance by means of flippantly distributing mass and torsional stiffness. Torque is applied radially to the gears and is transmitted radially with out setting stress at the gear tooth.

Sun Gear

The solar tools is the relevant gear of the planetary equipment and absorbs the riding force of the gears. The solar tools is pushed by using the pressure shaft, so the planetary gear can force the hoop gear. The structure of the planetary equipment is such that the pinion of the service attached to the planetary gear meshes with the solar gear.

Planetary Gear

The planetary gears are attached to the carrier and circulate in accordance with the motion of the sun tools. As it rotates relative to the sun gear, its teeth mesh with the tooth of the ring gear. When a planetary equipment actions, it revolves across the sun and the ring gear. A planetary gear has one or extra planetary gears and controls the speed of strength transmission.

Ring Gear

The outer ring of a planetary equipment machine is the hoop gear or ring gear. It has teeth on its internal circumference and a smooth outer edge. The tooth of the planetary wheels are grew to become inward to mesh with the planet gears. The carrier and planet gears are surrounded by using a ring tools that is constant in position. All the tooth of the planetary gears mesh with the sun gear and the hoop gear. As the planetary gears rotate around the solar gear, the ring gear is pressured to rotate within the same course as the sun equipment.

Carrier

The planetary gears are established on a carrier which connects their centres to the sun equipment, making sure that the pitch circles of the planetary gears mesh collectively on the way to roll without slipping. The carrier is commonly movable and rotates relative to the sun equipment. It is connected to the middle of every planet tools and affords help. Compound planetary gears have numerous specific gears and end up greater complicated as the variety of planet gears increases.

Planetary Gear Construction

Planetary gears require more than one inputs to be described to attain a selected output. The sun tools is on the center of the meeting and meshes with the tooth of the planet gears. The planet gears are small and related to a assist frame manufactured from aluminum, cast iron, or metal. A carrier consists of the shafts of every planet equipment, and the planet gears surround the solar equipment, that’s similarly surrounded by a hoop gear.

Planetary tools designs can include spur or helical gears. The difference between the two gears is the helix perspective. Spur gears have a helix angle of 0 levels, whilst helical gears have a helix perspective of 10 to 30 ranges. In both kinds of gears, bearings play a essential position in the torque transmission of planetary gears. Needle bearings are sized accurately however can’t resist axial forces. The perfect bearing type for axial forces is a tapered roller bearing, which is larger than a needle bearing.

Conclusion

- A planetary equipment is a kind of tools machine wherein three or greater gears, referred to as planets, rotate round a principal equipment (sun equipment) that acts because the input equipment.

- Planetary gears are reduction gears used in vehicle and off-street automobile transmissions, wheel drives, and business conveyor belts. They are regarded for their high translatability, compact design, and sturdiness, making them perfect for uncommon and unique programs.

- Planetary gears are a manner of changing reciprocating movement into rotary movement. They have been evolved in 1781 with the aid of William Murdoch for use in steam engines, changing the crank used to create rotary movement. A common application of planetary gears is velocity discount in constrained areas.

- Planetary gears require multiple inputs to be defined to attain a particular output.

- Different varieties of planetary gears have distinct performance, performance, and versatility. Each kind has the capability to convert two inputs into one output, which makes them complicated to construct and analyze.