Introduction

This blog will take an in-depth look at Cotter Joint. The blog will bring more detail on topics such as:

- What Is A Cotter Joint?

- Cotter Joint Types

- Cotter Joint Application

- Cotter Joint Assembly

- Failure Of Cotter Joint

- Advantages And Disadvantages Of Cotter Joints

- Related FAQs

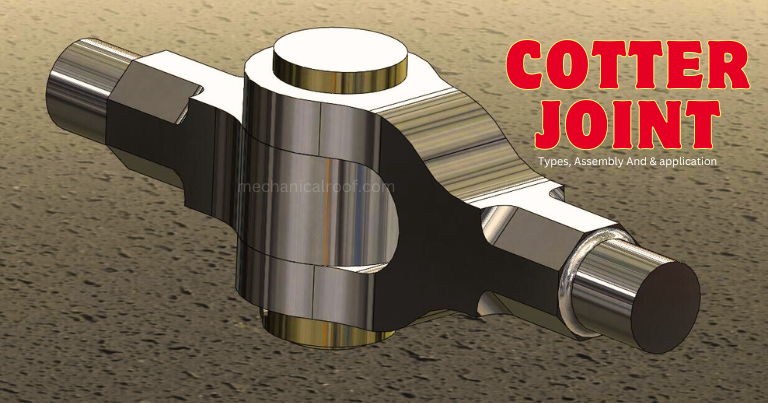

What Is A Cotter Joint?

A cotter joint, also known as a socket and spigot joint, is a quick connection between two coaxial rods. One rod has a spigot, which fits the intern kit in one place on the opposite rod. The slots in the socket and spigot align so that the cotter can be inserted to secure the 2 rods together.

Cotter joints are used to transfer axial loads between two rods, either rigid or compressive. Although the cotter joint will face the rotation of 1 rod to another, it should not be used to register rotating shafts. This is due to the fact that the cotter will no longer be balanced and can be unfastened under the aggregate of vibration and centrifugal force.

Cotter Joint Types

Following are the 3 varieties of cotter joints to attach two rods via a cotter:

1- Socket and spigot cotter joint 2- Sleeve and cotter joint 3- Gib and cotter joint

1- Socket and spigot cotter joint

A cotter joint called a socket and spigot joint, is a method of briefly becoming a member of two coaxial rods, one stop of the rod furnished with a socket type and the opposite cease of the alternative rod inserted into the socket. The end of the rod goes right into a socket also called a spigot.

A rectangular hole is constructed into the socket and spigot. A cotter is tightly working via a hole to make a transient connection between the 2 rods. The load is normally appearing axially, but it modifications its route. And so, the cotter joint should be designed to carry both tensile and compressive loads. Compressive load is taken by means of the caller at the spigot.

2- Sleeve and cotter joint

A sleeve and cotter joint is a type of joint used to connect parallel coaxial cylindrical rods. It includes sleeves and tapered checker-shaped cotters. Suitable slots are cut inside the sleeve and inside the cylindrical rods.

The cotter is mounted in those slots. The taper of the cotter is commonly 1 in 24. It may also be noticed that the taper aspects of the two cottars need to face every other. The clearance is so adjusted that once the coaters are driven in rods, they arrive close to every other and as a result tighten the joint.

The sleeve and cotter joint is the only cotter joint in existence. It is quite rigid and may take both tensile and compressive hundreds. It can be effortlessly assembled and dismantled. The joint can also be used to attach comparable pipes and tubes.

Rectangular rods and diverse cylindrical rods can’t join using this joint. A sleeve and cotter joint no longer allow angular misalignment among its cylindrical contributors. It can not join cylindrical contributors which undergo rotation.

3- Gib and cotter joint

A Gib and cotter joint is usually utilized at the strap end or the massive cease of a connecting rod. In some cases, when the cotter along i.e Ewithoutt gib is administered. The friction between its ends and the inside slot inside the strap reasons the rims of the strap to open outward.

To prevent this, Gib is used that hold the ends of the strap collectively. In addition, the gator gives a larger bearing floor for the cotter to slip because the preserving strength will increase. Thus, the friction of the cotter reduces the tendency to slack lower back. Gib additionally allows parallel holes to apply.

Gib and cotter joints are used for rods of square or square pass-sections. The quit of one rod fits the top of the alternative rod which is made in the shape of a strap. A gib is used in conjunction with the cotter to make these joints. Gib is probably a cotter but with gib heads at its ends.

- When one gib is used, the cotter with one aspect tapered is furnished and the gib is constantly on the outside.

- When gibs are used, the cotter with each aspect tapered is supplied.

- Sometimes to prevent loosening of the cotter, a small set screw is used via the rod jamming against the cotter.

Cotter Joint Application

Cotter joint applications are as follows.

- It is used to connect piston rods to the crosshead in a steam engine.

- It is used to connect the piston rod to its extension.

- It is also used on bikes to connect pedals to sprocket wheels.

- Foundation bolt

- Joint between slide spindle and valve mechanism forks

- Cotter and dowel arrangement for joining the two halves of the flywheel.

- Use to connect the tail rod to the piston rod of the wet air pump.

- It is used to connect two rods of the same diameter under axial forces.

- The cotter joint is used to connect the extension of the piston rod to the crosshead in an automobile engine.

- Historically, steam engines used cotter joints to connect connecting rods and pumps to drain mines.

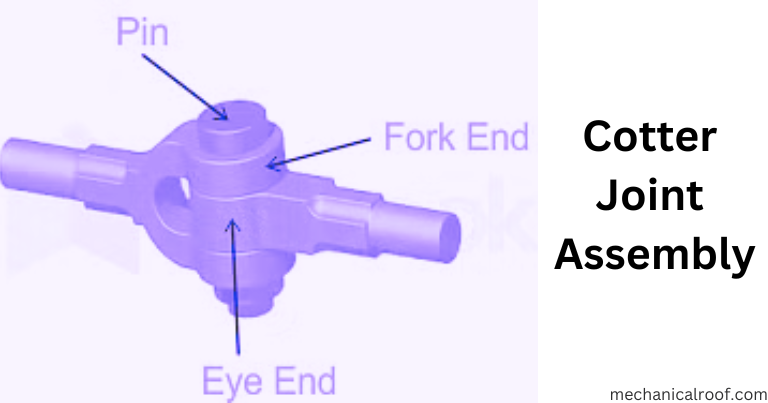

Cotter Joint Assembly

The Cotter United has 3 components:

- Spigot:

- Socket:

- Cotter:

1-Spigot:

This is the male part of the joint and has a rectangular slot to pass the coater through. The spigot has a collar that rests on the end of the coil.

2-Socket:

This is the female part of the joint, it also has a rectangular slot for passing the cotter. It has a circular hole into which a spigot fits.

3-Cotter:

This is a wedge-shaped piece of metal that actually connects two non-rotating parts.

A cotter is a flat wedge-shaped piece of metal, used to connect two rods that transmit force but do not rotate. The force may be axial or tensile in nature or compressive.

The cotter is mounted in a tapered slot and remains in place by the wedge action. This happens because of the cone. Normally the cost of a taper on a coater ranges from 1 in 48 to 1 in 24 and offers two main

Advantages: First, this taper is easy to remove and disassembling joints is a simple process.

Failure Of Cotter Joint

When the cotter joint tightened between the socket and spigot slots, it was exposed to shear stresses. Then if the cotter is loose, the cotter will be bent. The various failure modes of cotter joints are discussed below.

1- Failure of rods in tension

2- Spigot failure in tension across the weakest section

3- Rod or coater failure in crushing

4- Socket failure in tension across the slot

5- Coater failure in shear

6- Inside socket collar failure Crushing

7- Socket end failure in shear

8- Shear rod end failure of the collar Failure

9- Failure of the bending coater

Advantages And Disadvantages Of Cotter Joints

Advantages Of Cotter Joints

- Cotter joints can be easily made, and after re-joining the parts are always in the same position.

- Cotter joints can be used to connect the same pipe.

- Assembling and disassembling the cotter joint parts is quick and easy and requires no special effort.

- Cotter joints are simple and easy to manufacture and reach the markets.

- Very tough and can take both hard and compressive loads.

Disadvantages Of Cotter Joints

- Rectangular rods and odd cylindrical rods cannot be connected using this joint.

- Sleeve-cotter joints that cannot connect cylindrical members are rotated.

Related FAQs

What is cotter joint?

Answer: A cotter joint is a form of temporary joint where coaxial rods are linked the use of a spigot and socket assembly. The rod with the spigot quit is inserted inside the socket hollow space. There is a square slot on the spigot and socket via which the cotter is handed. Cotter acts as a key to block the slippage.

Where cotter joint is used?

Answer: Cotter’s joint is used to enroll in shafts which are in Rotation. Cotter’s joint is used while the contributors are subjected to Axial Tensile or Compressive Loading. It isn’t used to connect the shafts which are rotating or transmitting torque. E.G. Joint among the piston rod and the crosshead of a steam engine.

What is cotter joint and its application?

Answer: Basically Cotter joint is used to connect to co-axial rods, that are subjected to axial tensile or compressive pressure. Applications of cotter joint are: Joint among the piston rod and crosshead of steam engine. Joint among the slide spindle and the fork of valve mechanism.

Types of cotter joint?

Answer: Following are the 3 forms of cotter joint to attach rods via a cotter:

• Socket and spigot cotter joint.

• Sleeve and cotter joint.

• Gib and cotter joint.

How a cotter joint is made?

Answer: In a cotter joint, two coaxial rods are joined the use of additives, socket, and spigot. One rod is outfitted with a spigot and this assembly is outfitted right into a socket on one end of every other rod.

What is the motive for the failure of the cotter joint?

Answer: A cotter joint is subjected to tensile load and corresponding tensile stresses are evolved inside the meeting. Different additives of the cotter joint experience either compressive or crushing stresses. These stresses can set off failure of the joint.

Which kind of healthy is used in cotter joint?

Answer: A cotter-primarily based joint comes with another call a socket or spigot joint. It comes with a way of briefly becoming a member of among two coaxial rods and out of two rods; one is outfitted with a spigot that suits inner a socket on one cease of the alternative rod.

Is cotter joint a brief joint?

Answer: Cotter and pin joints are temporary joints. A cotter joint is beneficial for becoming a member of two rods/shafts which can be axial for the transmission of motion from one shaft to different.

Why are cotter joints tapered?

Answer: The cotter has a uniform thickness and the width ‘b’ is given a mild taper. The taper in the cotter is furnished to take benefit of wedging movement (friction locking). Due to the tapered form, it is easy to eliminate the cotter and dismantle the joint. The taper of the cotter, as well as slots, is on one facet.

Why gibs are used in cotter joint?

Answer: Gib is a counterpart of cotter furnished to prevent the axial motion of cotter while it is being hammered into the pressure. Because of tapered area, the cotter has the tendency to slide out due to vibrations. When the cotter is used with gib this tendency is decreased.

Where is Cotter pin used?

Answer: A cotter pin is a simple fastener it really is used to secure a bolt in vicinity. Consisting of a U-shaped piece of metal, it’s inserted through the hole of a bolt, and then the ends are twisted collectively. The cotter pin secures the bolt in location so that it’s less probable to loosen and pop out.